Long-acting cold-resistant cable material and preparation method thereof

A cold-resistant and cable technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems such as affecting service life, reducing mechanical properties, breaking, etc., to enhance cold resistance, ensure cold resistance, and reduce embrittlement temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

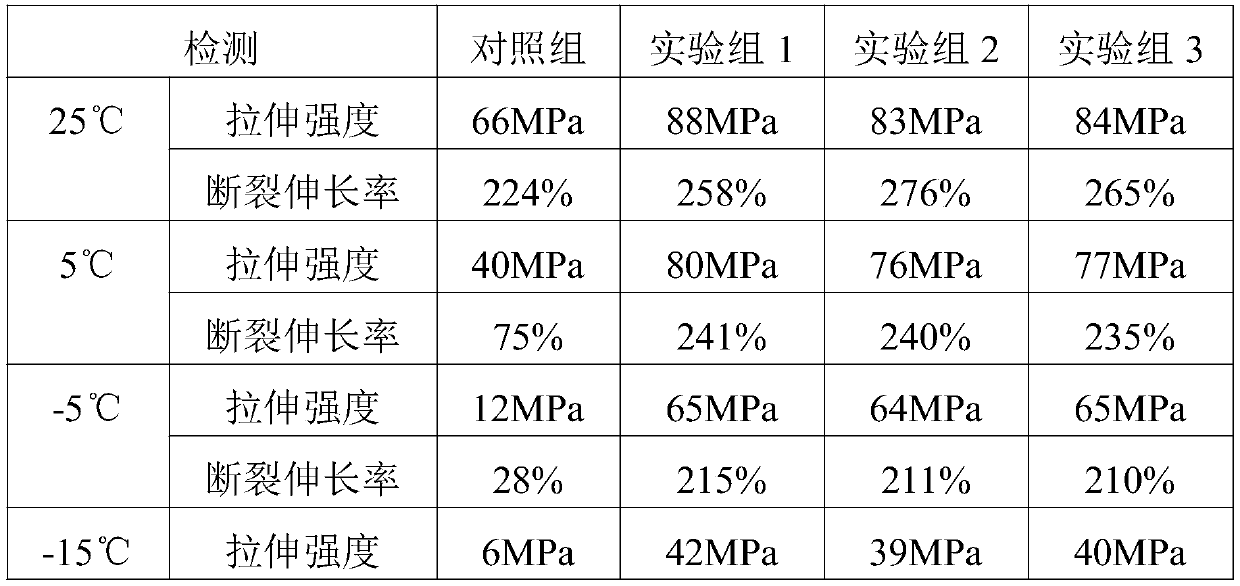

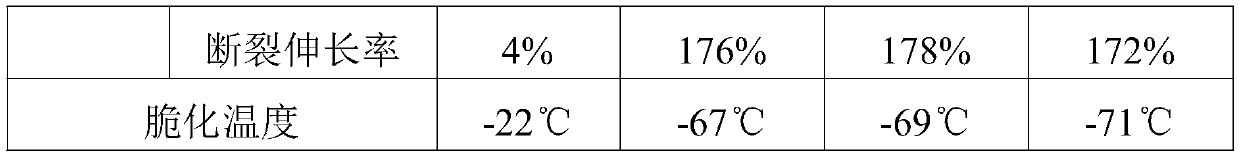

Examples

Embodiment 1

[0024] A long-acting cold-resistant cable material, the long-acting cold-resistant cable material is made of the following raw materials in parts by weight: 15 parts of ABS resin, 8 parts of EPDM rubber, 10 parts of polytetrafluoroethylene, 6 parts of fluorine rubber, poly 2 parts of dimethylsiloxane, 3 parts of dibutyl diglyceride adipate, 2 parts of ethoxyethoxyethyl acrylate, 1 part of dodecanedioic acid, 2 parts of basalt powder, fumed white carbon 2 parts of black, 1 part of crosslinking agent, 1 part of lubricant, 0.8 parts of antioxidant.

[0025] The crosslinking agent is a mixture of N, N-methylenebisacrylamide, dicumyl peroxide, and di-tert-butyl peroxide in a mass ratio of 3:1:1; the lubricant is zinc stearate , calcium stearate, polyethylene wax, ammonium bifluoride any two compositions; the antioxidant is 3,5-di-tert-butyl-4-carboxyphenyl isooctyl propionate, benzoyl peroxide, A mixture of ditetradecyl alcohol esters with a mass ratio of 3:2:1.

[0026] The prep...

Embodiment 2

[0033] A long-term cold-resistant cable material, the long-term cold-resistant cable material is made of the following raw materials in parts by weight: 20 parts of ABS resin, 12 parts of EPDM rubber, 15 parts of polytetrafluoroethylene, 8 parts of fluorine rubber, polytetrafluoroethylene 3 parts of dimethylsiloxane, 5 parts of dibutyl diglyceride adipate, 4 parts of ethoxyethoxyethyl acrylate, 2 parts of dodecanedibasic acid, 4 parts of basalt powder, fumed white carbon 4 parts black, 1.2 parts crosslinking agent, 1.6 parts lubricant, 1.2 parts antioxidant.

[0034] The crosslinking agent is a mixture of N, N-methylenebisacrylamide, dicumyl peroxide, and di-tert-butyl peroxide in a mass ratio of 3:1:1; the lubricant is zinc stearate , calcium stearate, polyethylene wax, ammonium bifluoride any two compositions; the antioxidant is 3,5-di-tert-butyl-4-carboxyphenyl isooctyl propionate, benzoyl peroxide, A mixture of ditetradecyl alcohol esters with a mass ratio of 3:2:1.

[0...

Embodiment 3

[0042] A long-acting cold-resistant cable material, the long-acting cold-resistant cable material is made of the following raw materials in parts by weight: 18 parts of ABS resin, 10 parts of EPDM rubber, 13 parts of polytetrafluoroethylene, 7 parts of fluorine rubber, polytetrafluoroethylene 2.5 parts of dimethylsiloxane, 4 parts of dibutyl diglyceride adipate, 3 parts of ethoxyethoxyethyl acrylate, 1.5 parts of dodecane dibasic acid, 3 parts of basalt powder, fumed white carbon 3 parts black, 1.1 parts crosslinking agent, 1.3 parts lubricant, 1 part antioxidant.

[0043]The crosslinking agent is a mixture of N, N-methylenebisacrylamide, dicumyl peroxide, and di-tert-butyl peroxide in a mass ratio of 3:1:1; the lubricant is zinc stearate , calcium stearate, polyethylene wax, ammonium bifluoride any two compositions; the antioxidant is 3,5-di-tert-butyl-4-carboxyphenyl isooctyl propionate, benzoyl peroxide, A mixture of ditetradecyl alcohol esters with a mass ratio of 3:2:1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com