Concrete formula for bridge construction and preparation method thereof

A bridge construction and concrete technology, applied in the field of concrete formulation and preparation for bridge construction, can solve the problems of acid-resistant and salt-resistant concrete without high performance, achieve high cohesion, improve salt-resistant performance, specific surface area, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

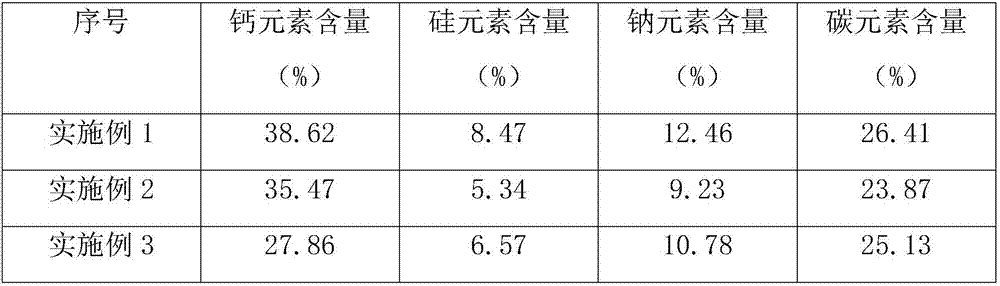

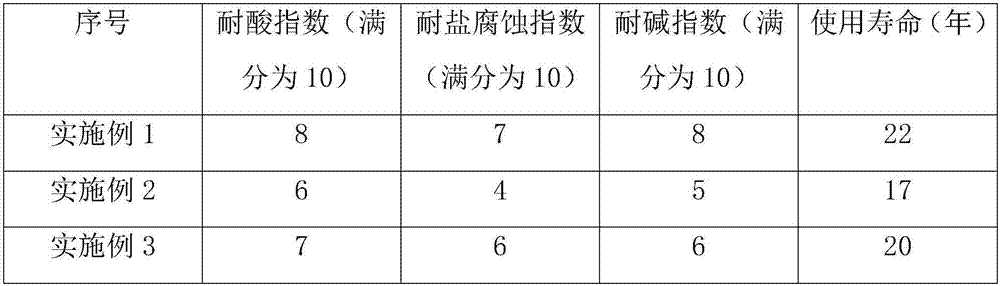

Embodiment 1

[0023] The invention provides a concrete formula for bridge construction, which comprises the following components in weight percent: 50% cement, 50% sand, 10% fly ash, 5% aggregate, 5% slag, 5% silicon powder, polyvinyl chloride 5%, water glass 5%, foaming agent 3%, foam stabilizer 0.6%.

[0024] The preparation method is as follows:

[0025] Step 1: Put the sand into the mixing chamber and stir thoroughly for 5-10 minutes, then screen the stirred sand through a screen, leaving a fineness modulus of 2.66, a bulk density of 1490kg / m3, and an apparent density of 2430kg / m3, fine sand with a mud content of 0.7%;

[0026] Step 2: Pour the fine sand and fly ash described in step 1 into the mixing bin, and fully stir for 5 to 10 minutes, so that the fine sand and fly ash are fully fused, and the particle size of the mixture is less than 5mm;

[0027] Step 3: put the aggregate into the grinding tube, and grind it fully for 15-20 minutes, so that the aggregate can form a bone powde...

Embodiment 2

[0039] The invention provides a concrete formula for bridge construction, which comprises the following components in weight percent: 40% cement, 20% sand, 3% fly ash, 3% aggregate, 3% slag, 3% silicon powder, polyvinyl chloride 2%, water glass 2%, foaming agent 1%, foam stabilizer 0.3%.

[0040] The preparation method is as follows:

[0041]Step 1: Put the sand into the mixing chamber and stir thoroughly for 5-10 minutes, then screen the stirred sand through a screen, leaving a fineness modulus of 2.66, a bulk density of 1490kg / m3, and an apparent density of 2430kg / m3, fine sand with a mud content of 0.7%;

[0042] Step 2: Pour the fine sand and fly ash described in step 1 into the mixing bin, and fully stir for 5 to 10 minutes, so that the fine sand and fly ash are fully fused, and the particle size of the mixture is less than 5mm;

[0043] Step 3: put the aggregate into the grinding tube, and grind it fully for 15-20 minutes, so that the aggregate can form a bone powder ...

Embodiment 3

[0055] The invention provides a concrete formula for bridge construction, which comprises the following components in weight percent: 50% cement, 20% sand, 10% fly ash, 3% aggregate, 5% slag, 3% silicon powder, polyvinyl chloride 5%, water glass 2%, foaming agent 3%, foam stabilizer 0.3%.

[0056] The preparation method is as follows:

[0057] Step 1: Put the sand into the mixing chamber and stir thoroughly for 5-10 minutes, then screen the stirred sand through a screen, leaving a fineness modulus of 2.66, a bulk density of 1490kg / m3, and an apparent density of 2430kg / m3, fine sand with a mud content of 0.7%;

[0058] Step 2: Pour the fine sand and fly ash described in step 1 into the mixing bin, and fully stir for 5 to 10 minutes, so that the fine sand and fly ash are fully fused, and the particle size of the mixture is less than 5mm;

[0059] Step 3: put the aggregate into the grinding tube, and grind it fully for 15-20 minutes, so that the aggregate can form a bone powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com