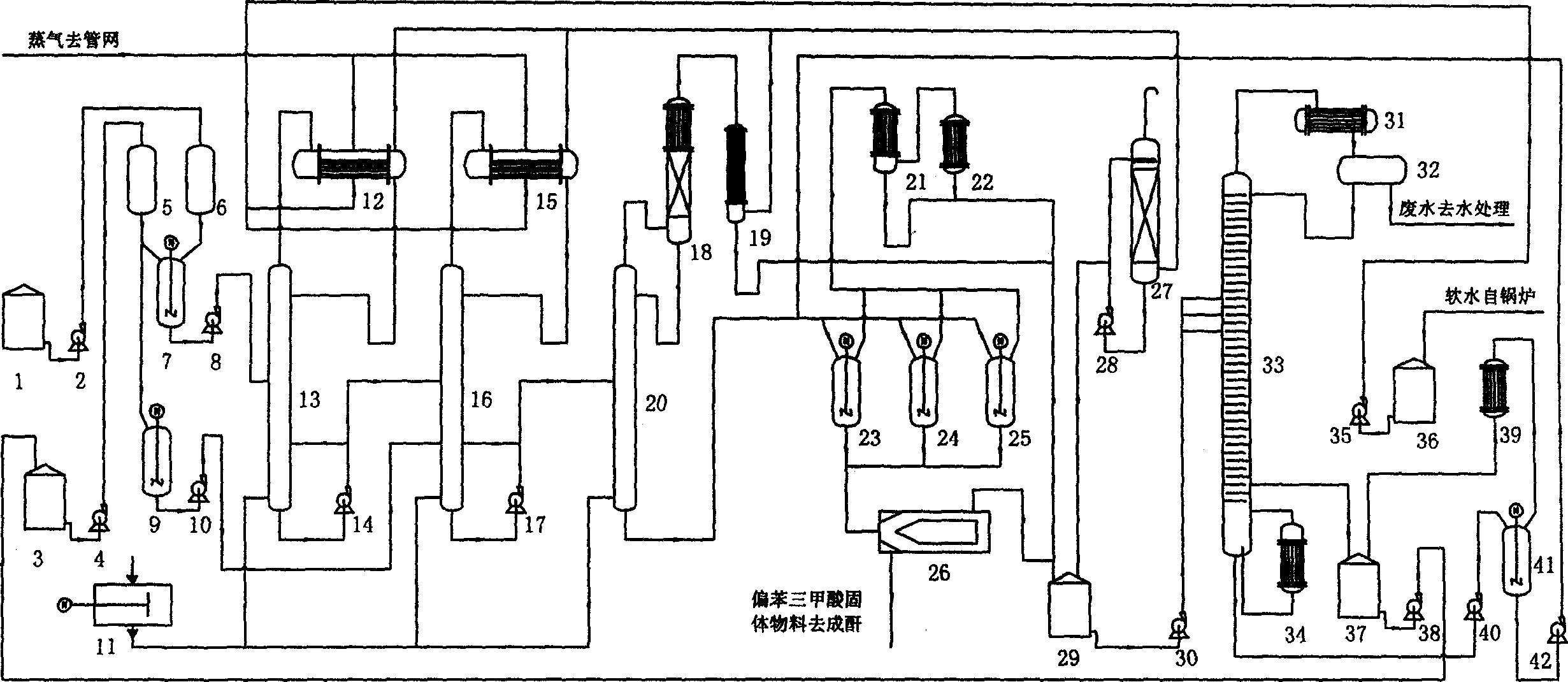

Method for producing meta benzene tricarbonic acid through sequential oxidation by using intermittent multiple cascaded Bubbling oxidation towers

A technology of trimellitic acid and oxidation tower, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. It can solve the problems of easy leakage and damage of moving sealing parts, easy blockage of crystallizer inlet, unfavorable crystal growth, etc. problems, achieve stable and reliable operation, improve energy conversion efficiency, and stabilize product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a) 1000Kg unimitylene is sent into 1# batching still 7 through metering tank 6 and 5 respectively from solvent tank 3 with delivery pump 2 and solvent pump 4 from raw material tank 1,4000Kg acetic acid solvent 4000Kg, weighs cobalt acetate, Put 4.5Kg each of manganese acetate and tetrabromoethane into 1# batching kettle 7, heat to 80°C, and stir fully at the same time until the catalyst is completely dissolved;

[0034] b) Turn on soft water pump 35 and add soft water to 1# condenser 12 and 2# oxidation condenser 15 to keep the soft water level at 60% to 80%; 3 / h is sent into 1# oxidation tower 13, stops charging when reaching setting liquid level 50%~60%, opens circulation pump 14 and circulates material in 1# oxidation tower 13, and the material in the tower is heated, simultaneously to Continuously feed compressed air 11 into the tower to gradually increase the temperature and pressure to initiate the oxidation reaction. After the initiation is successful, the tempe...

Embodiment 2

[0042] a) 1500Kg unimitylene from raw material tank 1, 7500Kg acetic acid solvent from solvent tank 3 with delivery pump 2 and solvent pump 4 are sent into 1# batching kettle 7 through metering tank 6 and 5 respectively, weigh cobalt acetate 4.5 respectively kg, manganese acetate 2.5kg, tetrabromoethane 3.8Kg drop into 1# batching kettle 7, measure acetic acid 300kg through measuring tank 5, weigh respectively cobalt acetate 2.5kg, manganese acetate 4.5kg, tetrabromoethane 3.8Kg drop into 2# The batching kettle 9 is heated to 80°C respectively, and at the same time, it is fully stirred until the catalyst is completely dissolved;

[0043] b) Turn on soft water pump 35 and add soft water to 1# condenser 12 and 2# oxidation condenser 15 to keep the soft water level at 60% to 80%; 3 / h is sent into 1# oxidation tower 13, stops charging when reaching setting liquid level 50%~60%, opens circulation pump 14 and circulates material in 1# oxidation tower 13, and the material in the tow...

Embodiment 3

[0050] a) 1000Kg unimitylene is sent into 1# batching kettle 7 through metering tank 6 and 5 from raw material tank 1, 6000Kg acetic acid solvent from solvent tank 3 with delivery pump 2 and solvent pump 4 respectively, and weighs cobalt acetate 4.0 respectively kg, manganese acetate 1.1kg, tetrabromoethane 2.4Kg drop into 1# batching kettle 7, measure acetic acid 300kg through measuring tank 5, weigh respectively cobalt acetate 1.1kg, manganese acetate 4.0kg, tetrabromoethane 3.0Kg drop into 2# The batching kettle 9 is heated to 80°C respectively, and at the same time, it is fully stirred until the catalyst is completely dissolved;

[0051] b) Turn on soft water pump 35 and add soft water to 1# condenser 12 and 2# oxidation condenser 15 to keep the soft water level at 60% to 80%; 3 / h is sent into 1# oxidation tower 13, stops charging when reaching setting liquid level 50%~60%, opens circulation pump 14 and circulates material in 1# oxidation tower 13, and the material in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com