Environment-friendly and energy-saving closed evaporative condenser

An evaporative condenser, environmental protection and energy-saving technology, applied in the direction of steam/steam condenser, lighting and heating equipment, etc., can solve the problems of easy freezing, many detours of serpentine tubes, and easy pollution of the medium, so as to reduce the continuous flow distance and improve Heat exchange effect, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

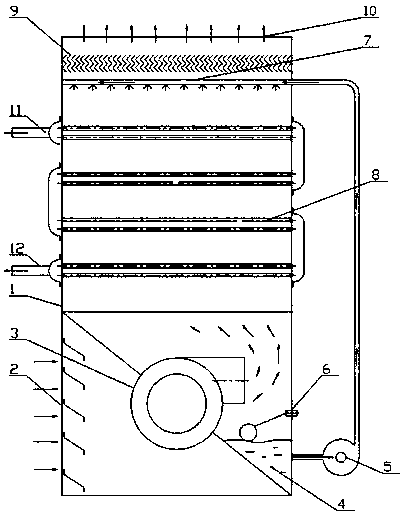

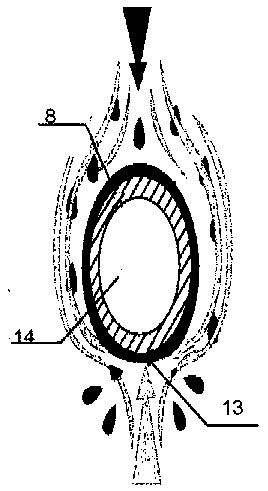

[0012] Figure 1 shows a schematic structural diagram of an environmentally friendly and energy-saving closed evaporative condenser. The figure includes box 1, air inlet duct 2, fan 3, water collection tank 4, water pump 5, float valve 6, spray water distributor 7, straight cooling pipe 8, water collecting plate 9, hot air outlet 10, water inlet 11. Water outlet 12; there is an air inlet channel 2 at the bottom of the box body 1, and a water collection tank 4 is provided on one side of the air inlet channel 2, and a float valve 6 is installed at the corresponding liquid level of the water collection tank 4, and a water pump is connected to the water collection tank 4 5. The other end of the water pump 5 is connected to the spray water distributor 7 on the top through a pipeline. The upper part of the spray water distributor 7 is provided with a water collecting plate 9, and the lower part is provided with a straight cooling pipe 8, and the straight cooling pipe 8 tube plate The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com