A microstructure mass transfer device

A technology of microstructure and equipment, applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problem that the reaction or mixing space cannot fully exert its efficiency, limit the solid content of the fluid, further increase the viscosity, and tortuous internal flow channels, etc. problems, to achieve good flexibility and adaptability, easy processing, and avoid fluid short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

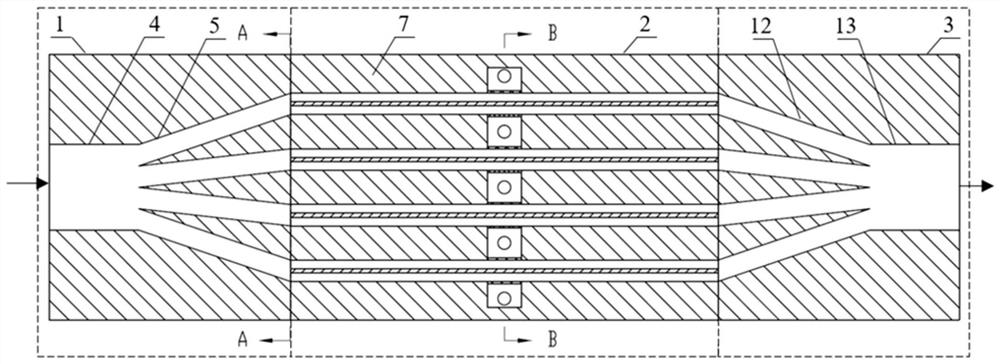

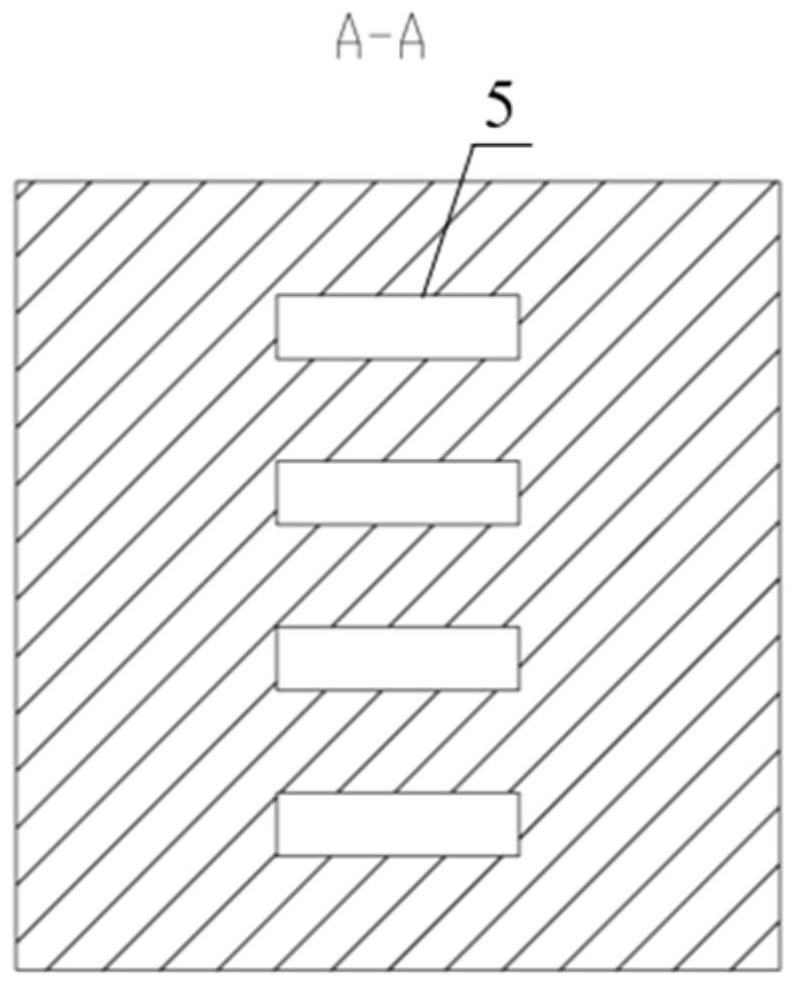

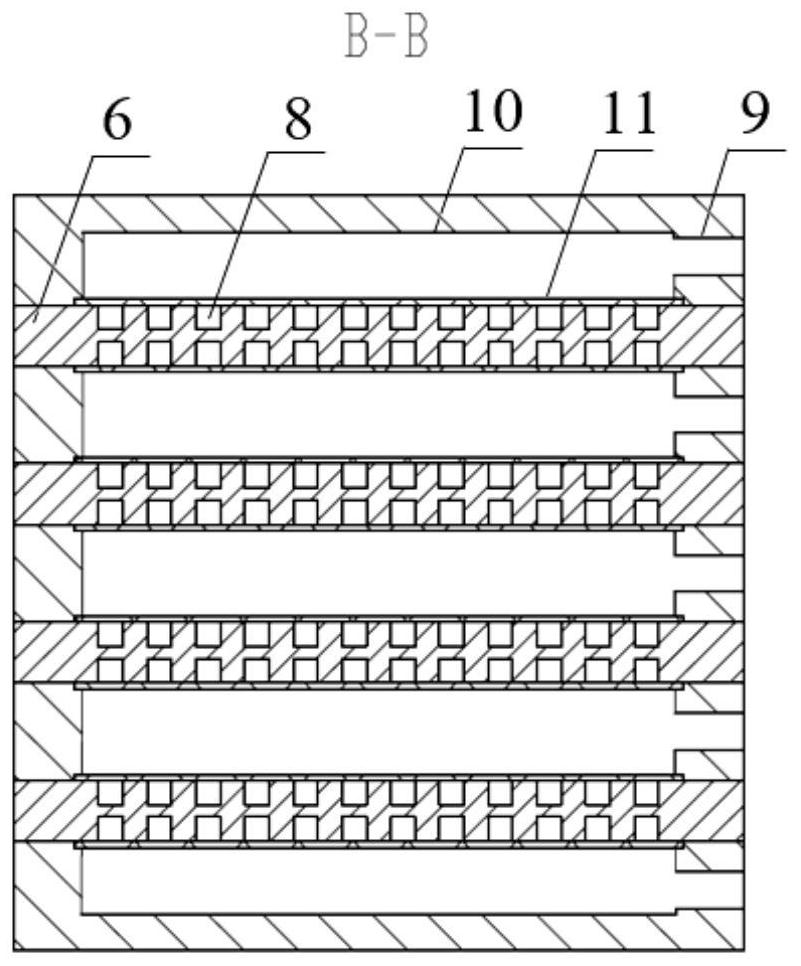

[0029] like figure 1 The illustrated embodiment of the invention comprises a fluid distribution section 1, a fluid mixing section 2 and a mixed fluid collection section 3 closely connected in sequence, wherein the fluid distribution section 1 is located at an upstream position, and the second fluid mixing section 2 is guided by N blocks of mixed fluids. The flow plate 7 and N-1 fluid separation plates 6 are stacked from top to bottom in a staggered manner, and the stacked mixed fluid flow deflectors 7 and fluid separation plates 6 are fixed and pasted by means of pressure fastening of outsourcing components. Combined to form a complete second fluid mixing section 2, the shapes of the fluid partition plate 6 and the mixing fluid deflector 7 match, and N is greater than or equal to 3.

[0030] The mixed fluid deflector 7 is a flat plate structure, and the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com