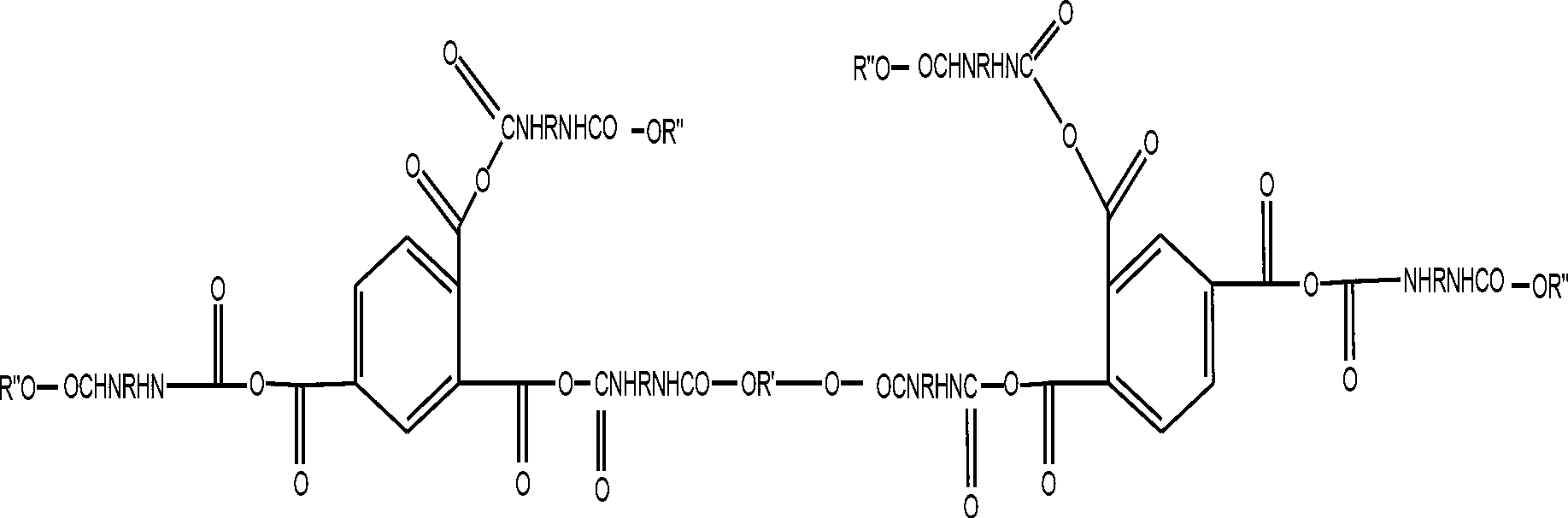

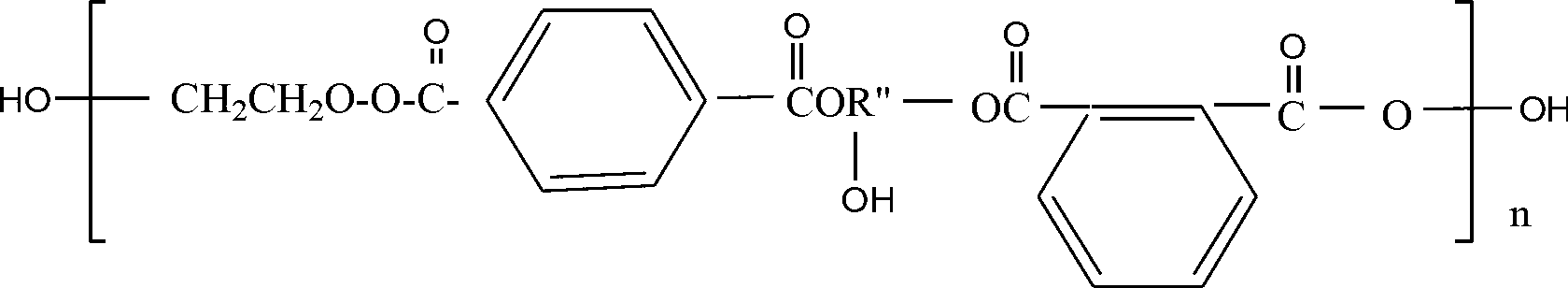

Environmentally-friendly modified heat-resistant polyester enameled wire paint and preparation method thereof

A polyester wire varnish and modification technology, which is applied in polyester coatings, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of difficult control of the coated wire surface, limited environmental protection effect, and unguaranteed enameled wire performance, etc. problems, to achieve the effect of improved flexibility, outstanding performance, and good molecular flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

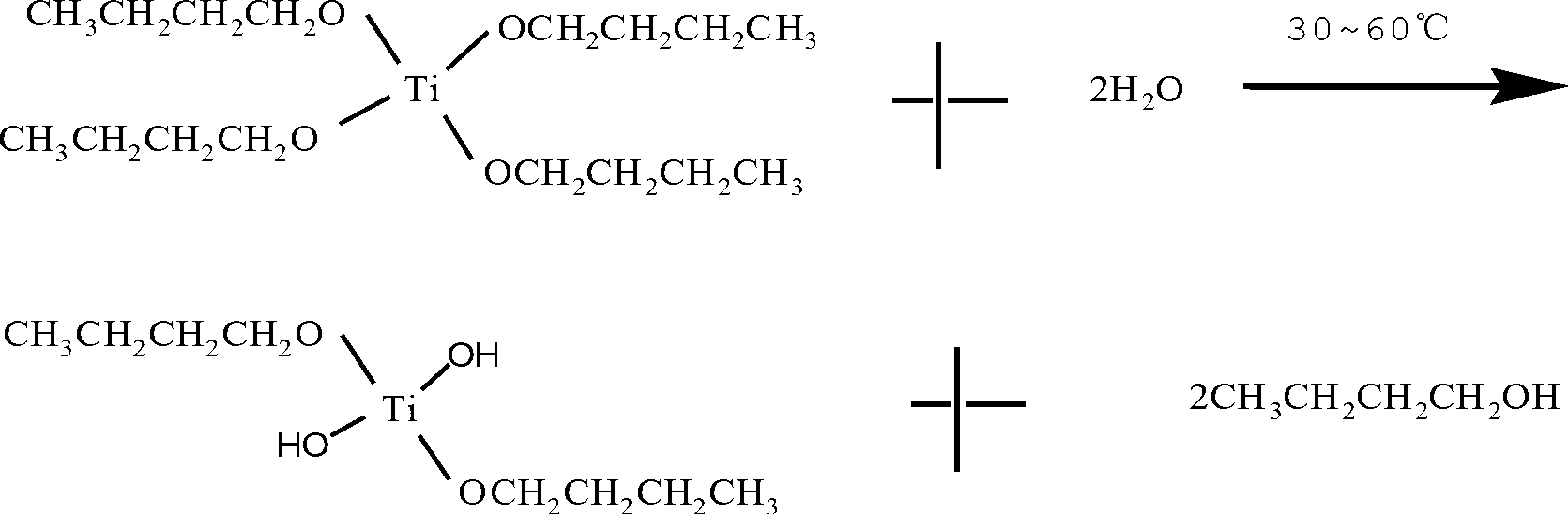

Method used

Image

Examples

Embodiment 1-1

[0066] Add 840 kg of ethylene glycol dimethyl ether into the reaction kettle and start stirring, then add 384.26 kg of trimellitic anhydride and raise the temperature to 80°C. After the material in the reaction kettle is transparent, slowly add 36 kg of water and control the temperature at 80°C to After reacting at 100°C for 2-4 hours, cool down to 60°C-65°C and add 1501.56 kg of MDI to react for 2 hours, raise the temperature to 100°C-120°C, react for 1-2 hours, then add 1,6-hexanediol 118.17 kg, heated up to 130°C to 140°C, and reacted for 2 to 5 hours; then added 432.52 kg of benzyl alcohol, and reacted at 130°C to 140°C for 3 to 5 hours. When the isocyanate content was less than 0.1%, the reaction was terminated and the When the temperature is lowered to 60°C-65°C, a TMA-D intermediate resin A with a solid content of 69.8% and a viscosity of 880mpas (30°C) is obtained.

Embodiment 1-2

[0068] Add 840 kg of ethylene glycol dimethyl ether into the reaction kettle and start stirring, then add 384.26 kg of trimellitic anhydride and raise the temperature to 80°C. After the material in the reaction kettle is transparent, slowly add 36 kg of water and control the temperature at 80°C to After reacting at 100°C for 2-4 hours, cool down to 60°C-65°C and add 1651.72 kg of MDI to react for 2 hours, raise the temperature to 100°C-120°C, react for 1-2 hours, then add 2,2-dimethyl- 104.15 kg of 1,3-propanediol, heated to 130°C-140°C, reacted for 2-5 hours; then added 436.58 kg of hydroxyl compound (phenol:xylenol = 1:1 molar ratio), reacted at 130°C-140°C After 3 to 5 hours, when the isocyanate content is less than 0.1%, the reaction is terminated, and the temperature is lowered to 60°C to 65°C to obtain TMA-D intermediate resin A with a solid content of 70.9% and a viscosity of 960mpas (30°C).

Embodiment 1-3

[0070] Add 840 kg of ethylene glycol dimethyl ether into the reaction kettle and start stirring, then add 384.26 kg of trimellitic anhydride and raise the temperature to 80°C. After the material in the reaction kettle is transparent, slowly add 36 kg of water and control the temperature at 80°C to After reacting at 100°C for 2-4 hours, cool down to 60°C-65°C and add 1080 kg of TDI to react for 2 hours, raise the temperature to 100°C-120°C, react for 1-2 hours, then add 62.03 kg of ethylene glycol, and heat up to 130°C ~140°C, react for 2~5 hours; then add 648.78 kg of cresol, react at 130°C~140°C for 3~5 hours, when the isocyanate content is less than 0.1%, stop the reaction and lower the temperature to 60°C~ 65°C, the TMA-D intermediate resin A with a solid content of 66.7% and a viscosity of 730mpas (30°C) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com