Spherical porous lithium manganate and preparation method and application thereof

A porous lithium manganese oxide, spherical technology, applied in the field of spherical porous lithium manganate and its preparation, can solve the problems of strict restrictions on manganese salts and lithium salts, potential safety hazards, complex processes, etc., to achieve good electrochemical performance, The effect of stable structure and mild preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

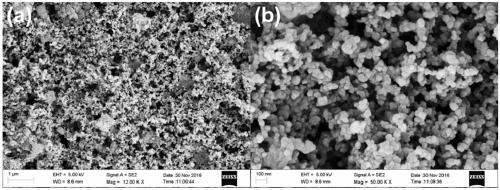

[0042] Solution A: Dissolve 0.49g of manganese acetate and 3g of polyvinylpyrrolidone in a mixed solvent of 50mL of deionized water and 50ml of ethanol, and stir until the solution is clear. Solution B: Dissolve 1.65 g of trimesic acid in a mixed solvent of 50 mL of deionized water and 50 mL of ethanol, and stir until the solution becomes clear. Then add solution B to solution A, react at room temperature for 24 hours, then centrifuge and dry to obtain an organic compound of manganese. Take 2g of lithium hydroxide and add it to the manganese organic compound, ball mill it evenly, and heat it at 500°C for 5 hours to get spherical porous lithium manganese oxide.

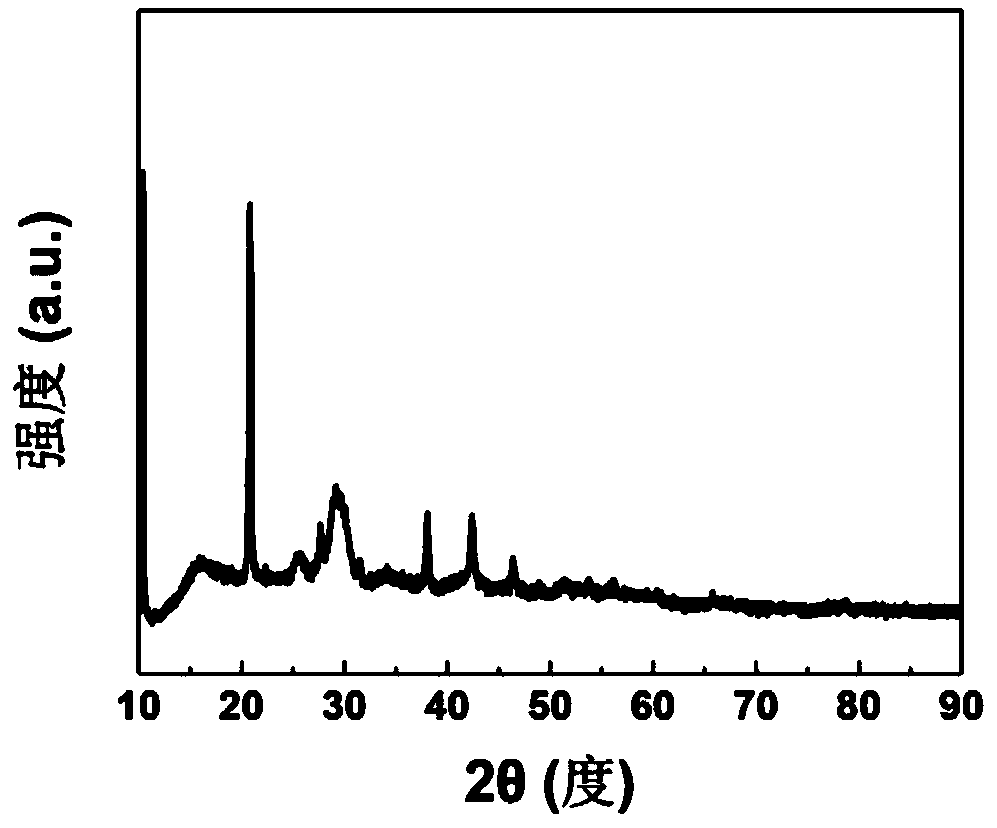

[0043] figure 1 It is the XRD figure of the organic compound of manganese in embodiment 1. It can be seen from the figure that there are no miscellaneous peaks, and the substance was successfully synthesized on the surface.

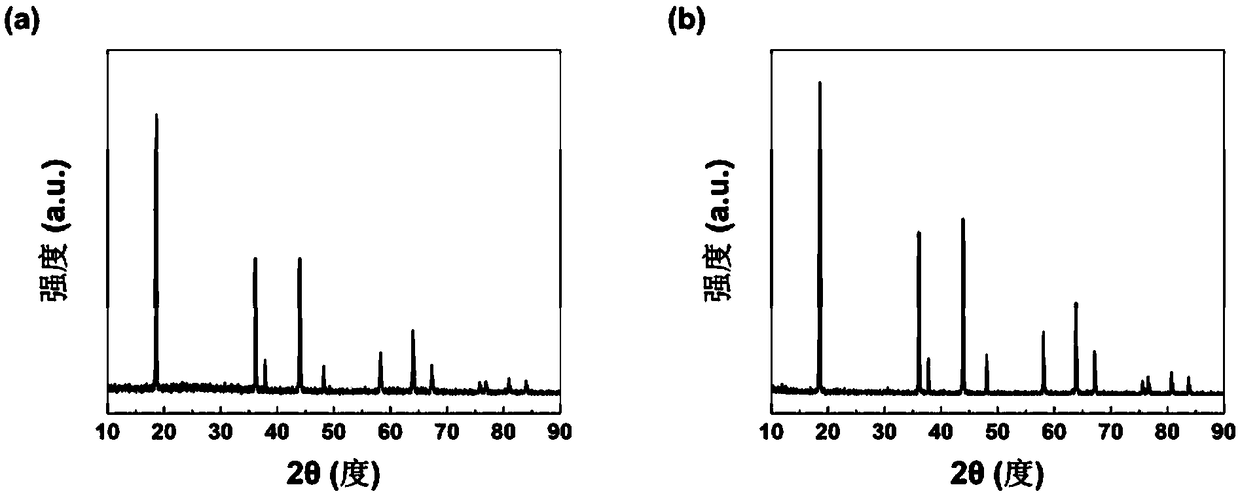

[0044] figure 2 It is the XRD figure of the lithium manganate (b) prepared in the purchas...

Embodiment 2

[0051] Solution A: Dissolve 0.6g of manganese chloride and 3g of polyvinylpyrrolidone in a mixed solvent of 50mL of deionized water and 50ml of ethanol, and stir until the solution is clear. Solution B: Dissolve 2.13g of terephthalic acid in a mixed solvent of 50mL of deionized water and 50ml of ethanol, and stir until the solution is clear. Then add solution B to solution A, react at room temperature for 10 hours, then centrifuge and dry to obtain the organic compound of manganese. Take 1.4g of lithium carbonate and add it to the manganese organic compound, ball mill it evenly, and heat it at 700°C for 10h to get spherical porous lithium manganese oxide. The particle diameter of the prepared lithium manganate is 110-160nm, and the pore diameter range is 250-300nm. Spherical porous LiMnO maintains a capacity of 102 mAh g after 100 cycles -1 .

Embodiment 3

[0053] Solution A: Dissolve 0.69g of manganese nitrate and 3g of polyvinylpyrrolidone in a mixed solvent of 50mL of deionized water and 50ml of ethanol, and stir until the solution is clear. Solution B: Dissolve 1.65 g of trimellitic acid in a mixed solvent of 50 mL of deionized water and 50 mL of ethanol, and stir until the solution is clear. Then add solution B to solution A, react at room temperature for 1 hour, then centrifuge and dry to obtain an organic compound of manganese. Take 1.2g of lithium sulfate and add it to the organic compound of manganese, ball mill it evenly, and heat it at 900°C for 5 hours to obtain spherical porous lithium manganese oxide. The particle diameter of the prepared lithium manganate is 150-180nm, and the pore diameter range is 200-300nm. Spherical porous LiMnO maintains a capacity of 99 mAh g after 100 cycles -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Aperture diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com