Preparation method of high-dispersion manganese-cerium composite oxides

A composite oxide and manganese-cerium technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as the inability to achieve high dispersion of manganese and cerium, and achieve Excellent reactivity and stability, mild preparation process and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Manganese-cerium composite oxide was prepared according to the following process

[0018] 1) According to the required ratio of manganese and cerium, configure a potassium permanganate, manganese acetate, cerium nitrate solution and a concentration of 0.2mol / L potassium hydroxide solution with a concentration of 0.1mol / L;

[0019] 2) Under the condition of vigorous stirring at 50°C, add the above solution dropwise, mix, and continue to stir for 1 hour after the dropwise addition is completed;

[0020] 3) The resulting precipitate was washed with hot water at 50°C, filtered with suction, and dried at 110°C for 8 hours. The obtained precursor was designated as S 1 . continue to S 1 The precursor was calcined at 500°C for 2 hours, and the obtained manganese-cerium composite oxide was denoted as S 2 .

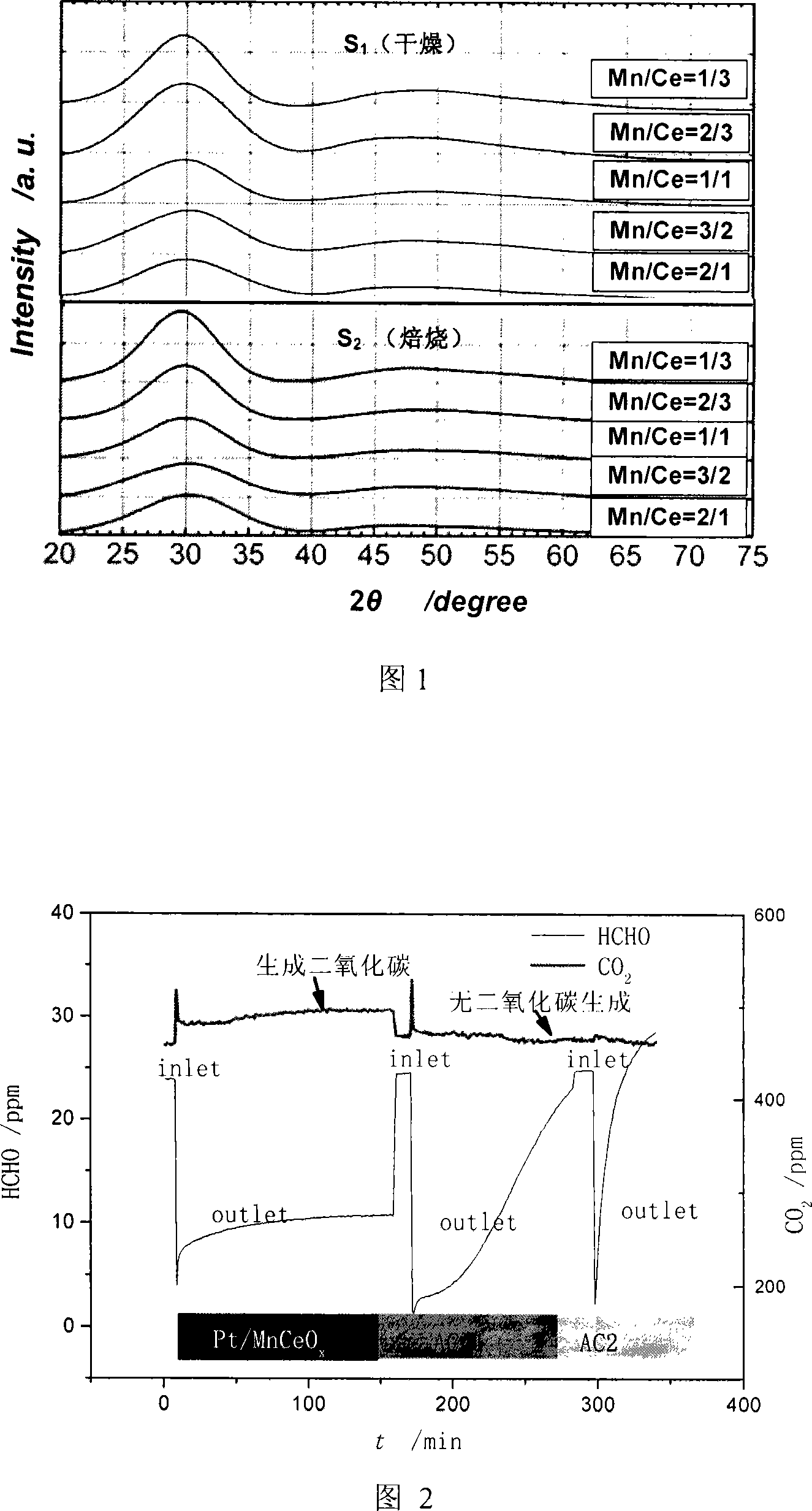

[0021] from S 1 and S 2 Appropriate amount of samples were taken for BET analysis, Raman spectrum analysis and XRD analysis (Fig. 1). BET analysis results showed that...

Embodiment 2

[0023] According to the steps in Example 1, a manganese-cerium composite oxide with a manganese-cerium ratio of 1:1 was prepared. Based on 0.25wt% Pt content, the manganese-cerium composite oxide was impregnated with dinitrosodiammine platinum solution, dried at 110°C, and activated at 450°C for 2 hours to obtain Pt-loaded manganese-cerium composite oxide Pt / MnCeOx .

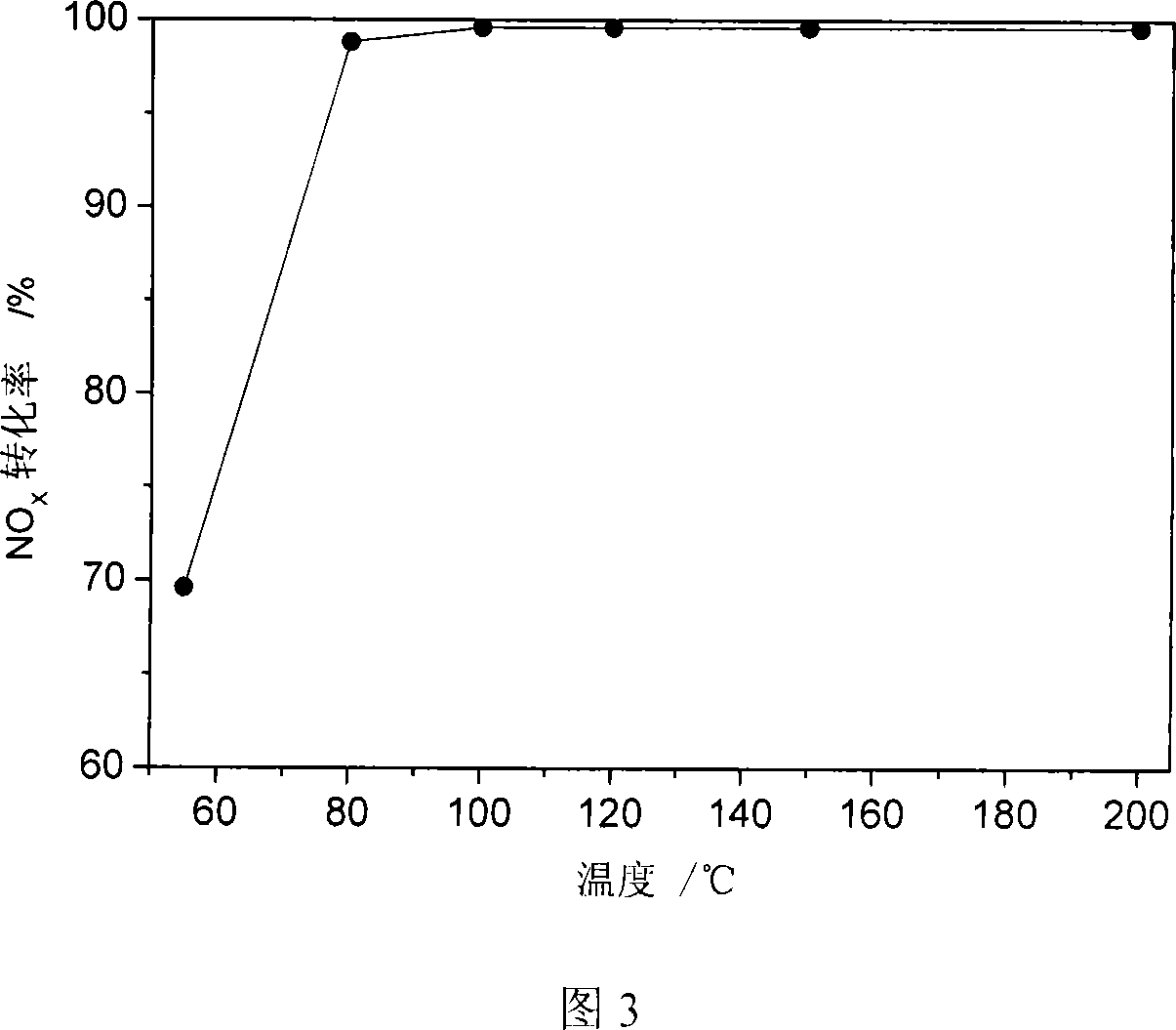

[0024] 0.3g Pt / MnCeOx was placed in a quartz fixed catalytic reaction bed to evaluate the catalytic oxidation activity of formaldehyde at room temperature. The reaction temperature is 22°C, the relative humidity is 60%, the air flow rate is 3L / min, and the equivalent space velocity is about 400,000h -1 . At the same time, ordinary activated carbon (AC2) and expanded activated carbon (AC1) were used as comparison samples. The experimental results are shown in Figure 2. It can be seen from Figure 2 that although activated carbon has a certain ability to eliminate formaldehyde, it mainly relies on adsorption an...

Embodiment 3

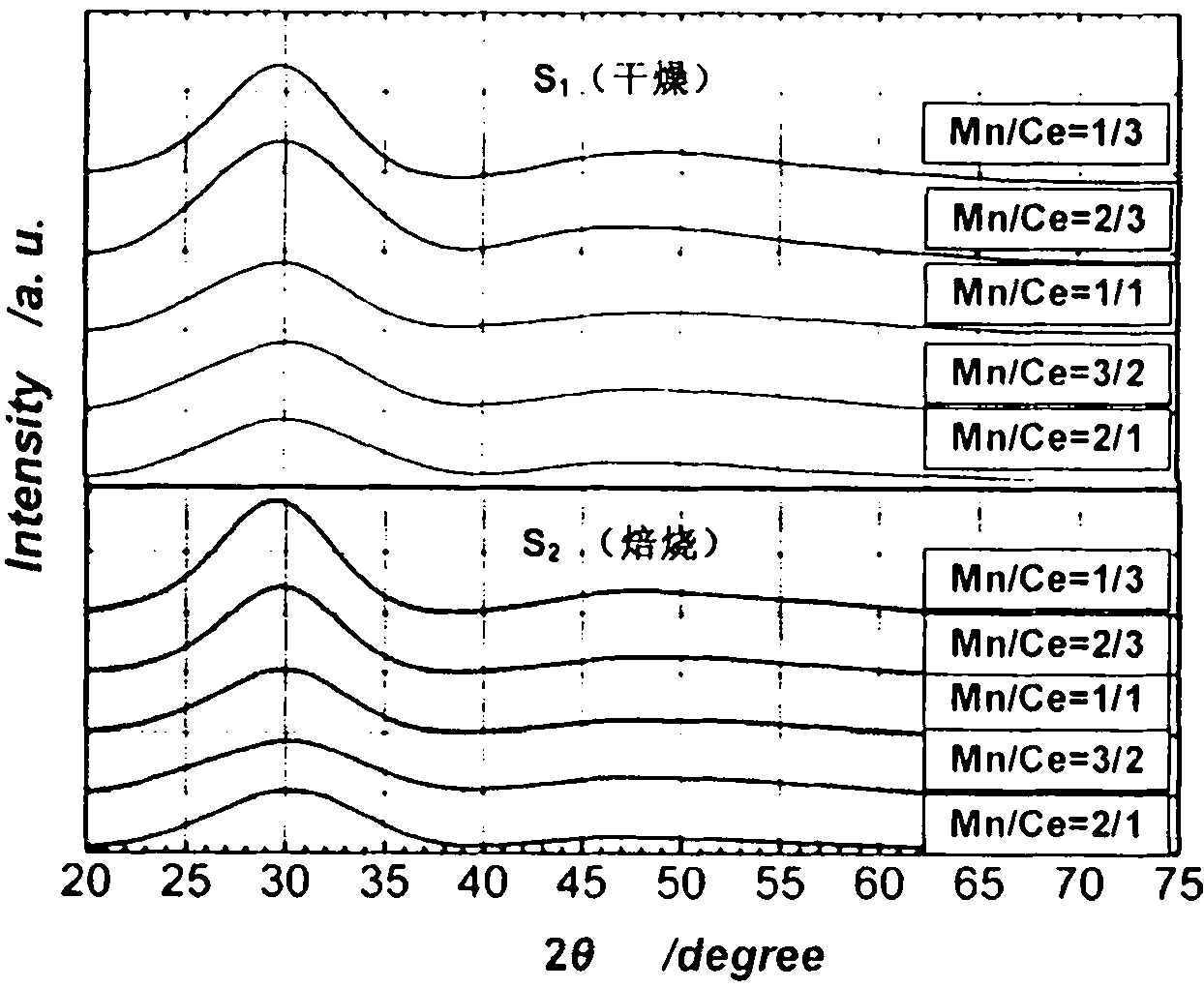

[0026] A manganese-cerium composite oxide with a manganese-cerium ratio of 3:1 was prepared according to the steps in Example 1. Take 0.3g MnCeOx and place it in a quartz fixed catalytic reaction bed for low temperature NH 3 Selective catalytic reduction of NOx(NH 3 -SCR) activity assessment. The reaction temperature is 50℃~200℃, NOx 500ppm, NH 3 500ppm, O 2 8%, H 2 O 5%, SO 2 0.1ppm, air speed 50,000h -1 . The experimental results are shown in Figure 3. As can be seen from Figure 3, MnCeOx on NH 3 -SCR has good low temperature activity. A NOx conversion rate of more than 70% can be achieved at around 60°C, and nearly 100% of NOx can be converted into N at a temperature above 80°C. 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com