Preparation method of high-yield 4, 4'-biphenol

A high-yield technology for biphenol, which is applied in the field of preparation of 4,4'biphenol, can solve the problems of difficult product purification, harsh reaction conditions, and high equipment requirements, and achieve easy product purification, fast reaction speed, The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

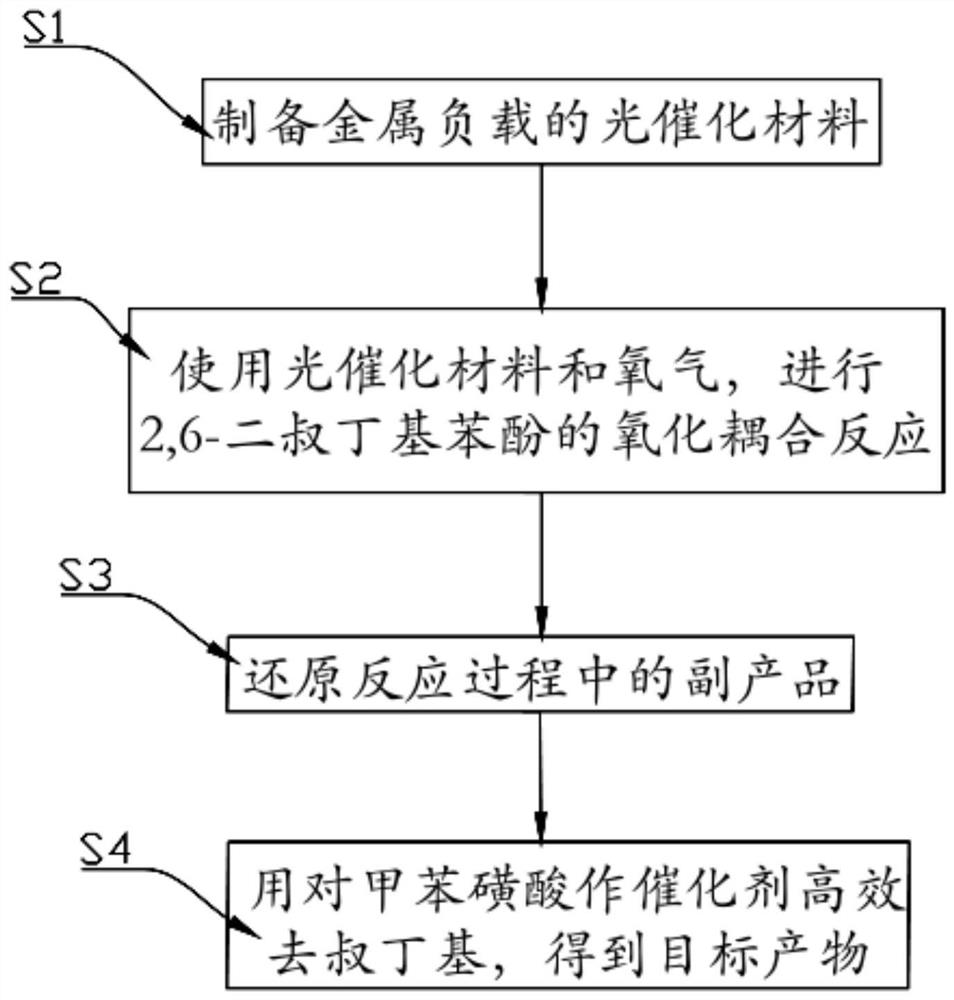

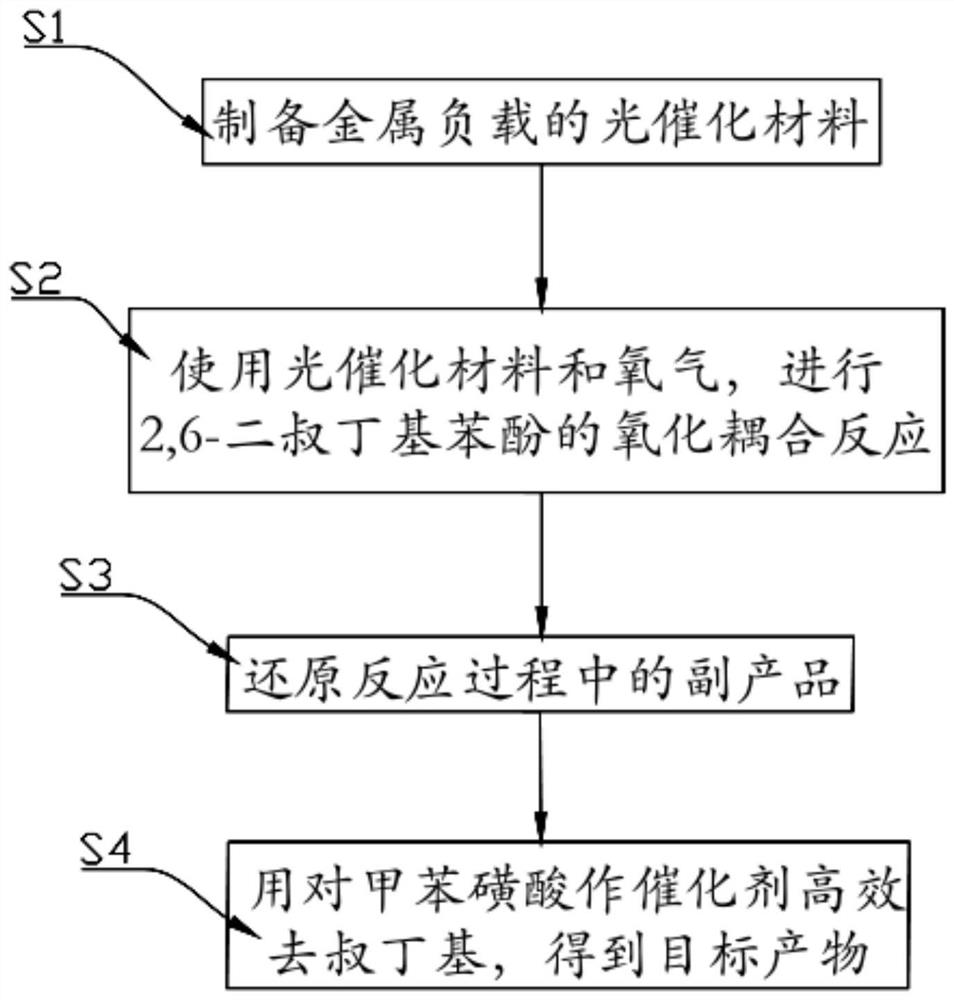

[0032] The preparation method of the high-yield 4,4'biphenyldiol of the present application is characterized in that it comprises the following steps:

[0033] S1: Utilizing metal sources on CeO 2 Loading is carried out to prepare a metal-loaded semiconductor material;

[0034] S2: After adding the metal-supported semiconductor material prepared in S1 and 2,6-di-tert-butylphenol into the reaction vessel, oxygen was introduced to carry out the oxidation coupling reaction of 2,6-di-tert-butylphenol, and then the The reaction product was filtered and dried to obtain product A;

[0035] S3: Add the product A and ethanol prepared in S2 into the reaction vessel, add the catalyst after it is completely dissolved, and perform a reduction reaction at 60-80°C for 1-3 hours with stirring, then spin evaporate the ethanol, and pump the remaining substance while it is hot After filtering, washing, and finally drying to obtain product B;

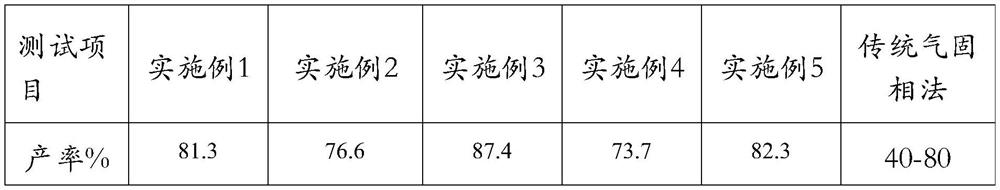

Embodiment 1

[0049] S1: Weigh 2g of CeO in a beaker 2 Nano powder, then add 20ml of lysine solution (concentration is 0.53mol / L), mix well and add 20ml of 0.1mol / L HAuCl 4 solution, and then move it to an oil bath at 80°C, slowly add 0.5mol / L sodium carbonate solution dropwise under stirring until the pH is 7, filter it with a Buchner funnel after constant temperature for 2 hours, and then filter the filter cake with a deionized Washed with water for 3 times, then placed it in an oven at 60 °C to dry, and finally dried the catalyst in N 2 Calcined in a muffle furnace at 400°C under protection for 4 hours, and after grinding, a noble metal-supported semiconductor catalyst was obtained;

[0050] S2: First add 2g of 2,6-di-tert-butylphenol into a 25mL three-necked flask, then add 5g of water and 0.2g of sodium dodecylbenzenesulfonate, stir for 20min and then add 0.02g of precious metal loaded For semiconductor catalysts, evacuate and then pass through O 2 , carry out oxidative coupling rea...

Embodiment 2

[0054] S1: Weigh 2g of CeO in a beaker 2 Nano powder, then add 20ml of lysine solution (concentration is 0.53mol / L), mix well and add 12ml of 0.1mol / L PdCl 2 solution, and then move it to an oil bath at 60°C, slowly add 0.5mol / L sodium carbonate solution dropwise under stirring until the pH is 7, filter it with a Buchner funnel after constant temperature for 3 hours, and then filter the filter cake with a deionized Washed with water for 3 times, then placed it in an oven at 60 °C to dry, and finally dried the catalyst in N 2 Calcined in a muffle furnace at 450°C under protection for 3 hours, and obtained a noble metal-supported semiconductor catalyst after grinding;

[0055] S2: First add 2g of 2,6-di-tert-butylphenol into a 25mL three-necked flask, then add 5g of water and 0.2g of sodium dodecylbenzenesulfonate, stir for 20min and then add 0.02g of precious metal loaded For semiconductor catalysts, evacuate and then pass through O 2 , carry out oxidative coupling reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com