Preparation method of medical intermediate 2,3,4-trimethoxy benzaldehyde

A technology of trimethoxybenzaldehyde and trihydroxybenzaldehyde, which is applied to pharmaceutical intermediates 2, to achieve the effects of increased market price, less equipment investment, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

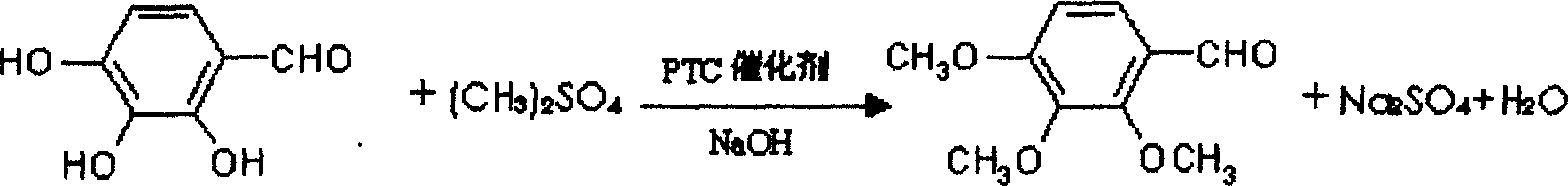

Method used

Image

Examples

Embodiment 1

[0012] Add 150 g of raw materials 2,3,4-trihydroxybenzaldehyde and an appropriate amount of water into a reactor with a thermometer, a stirrer and a heating jacket. After heating and dissolving, add the following materials into three times under stirring:

[0013] Concentration is 35% (weight) NaOH liquid 600mL, dimethyl sulfate 600g, catalyst trioctylmethylammonium chloride, tetrabutylammonium bromide 12g altogether.

[0014] The temperature in the reactor is maintained at 50-70°C, and the methylation reaction is carried out under stirring. After the methylation reaction was completed, the materials were allowed to stand and separate into layers. The upper layer was a yellow oil, and the lower layer was a mother liquor layer. After cooling, the mother liquor was removed, and the oil layer was washed with water to neutrality. The distillate was collected by distillation under reduced pressure, and 165 g of white crystals were obtained after cooling. . Through high-performance...

Embodiment 2

[0016] The preparation device is the same as in Example 1. Put 150g of 2,3,4-trihydroxybenzaldehyde into the reactor, dissolve at 50°C, add 25% NaOH aqueous solution 700mL, dimethyl sulfate 600g, phase transfer catalyst benzyltriethylammonium chloride and tetra 6g each of butylammonium bisulfate, after the methylation was completed, the crude product was separated, washed with water, and distilled to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com