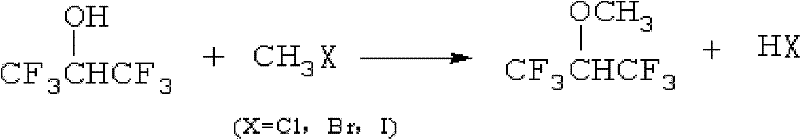

Preparation method of hexafluoroisopropyl methyl ether

A technology of hexafluoroisopropyl methyl ether and hexafluoroisopropanol, applied in 1 field, can solve the problems of high operating cost, low product yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add raw material hexafluoroisopropanol 70g, sodium hydroxide 15g, solvent acetonitrile 60g into a 0.25L pressure reactor, heat up to 40°C after mixing, slowly add 50g methyl iodide while stirring, keep constant temperature for 6 hours, and the reaction ends After cooling down, 52.7 g of the product hexafluoroisopropyl methyl ether was obtained by distillation, and the product yield was 82.3%.

Embodiment 2

[0024] Add 70g of raw material hexafluoroisopropanol, 20g of potassium hydroxide, and 50g of solvent dimethyl sulfoxide into a 0.25L pressure reactor, heat up to 50°C after mixing, slowly add 30g of methyl bromide under stirring, and react at constant temperature for 6 hours , Distilled after the reaction to obtain the product hexafluoroisopropyl methyl ether 43g, the product yield was 74.1%.

Embodiment 3

[0026] Add 80g of raw material hexafluoroisopropanol, 20g of sodium hydroxide, 60g of solvent N,N-dimethylformamide into a 0.25L pressure reactor, heat up to 60°C after mixing, and slowly add 40g of methyl chloride under stirring , constant temperature reaction for 6 hours, cooling down after the reaction, distillation to obtain the product hexafluoroisopropyl methyl ether 58.7g, product yield 67.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com