ZIF-67@MXene composite material as well as preparation method and application thereof

A technology of ZIF-67 and composite materials, applied in electrolytic components, electrodes, electrolytic process, etc., can solve problems such as poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of ZIF-67@MXene composite material, comprising the following steps:

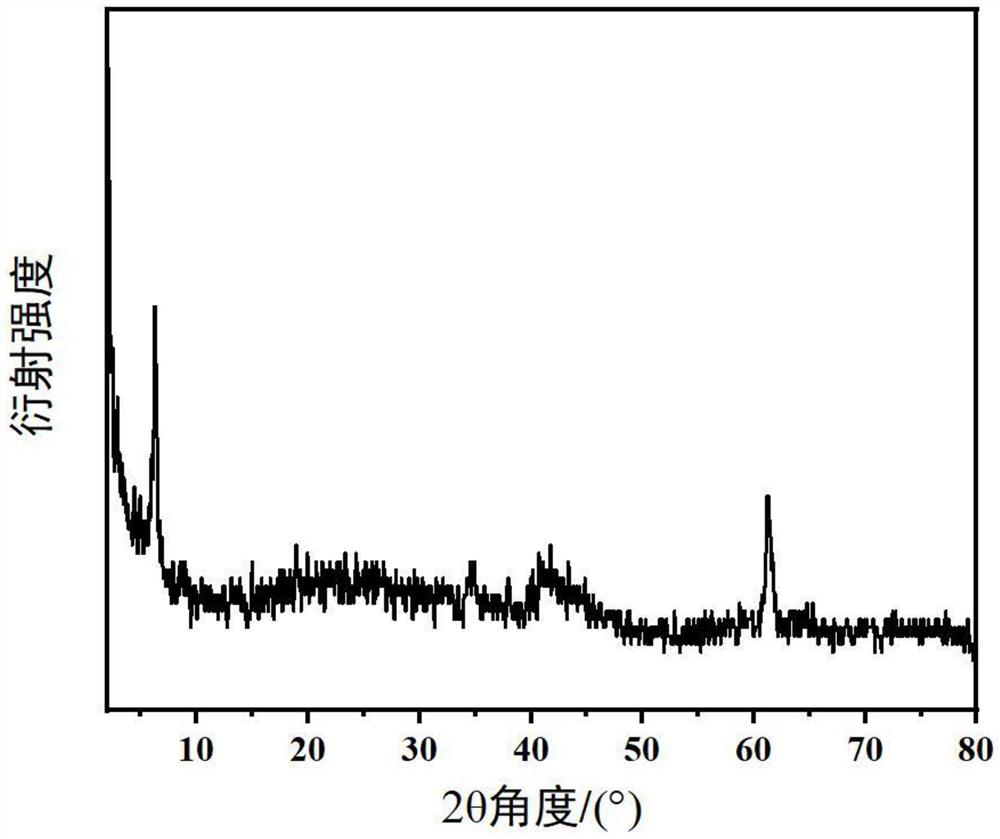

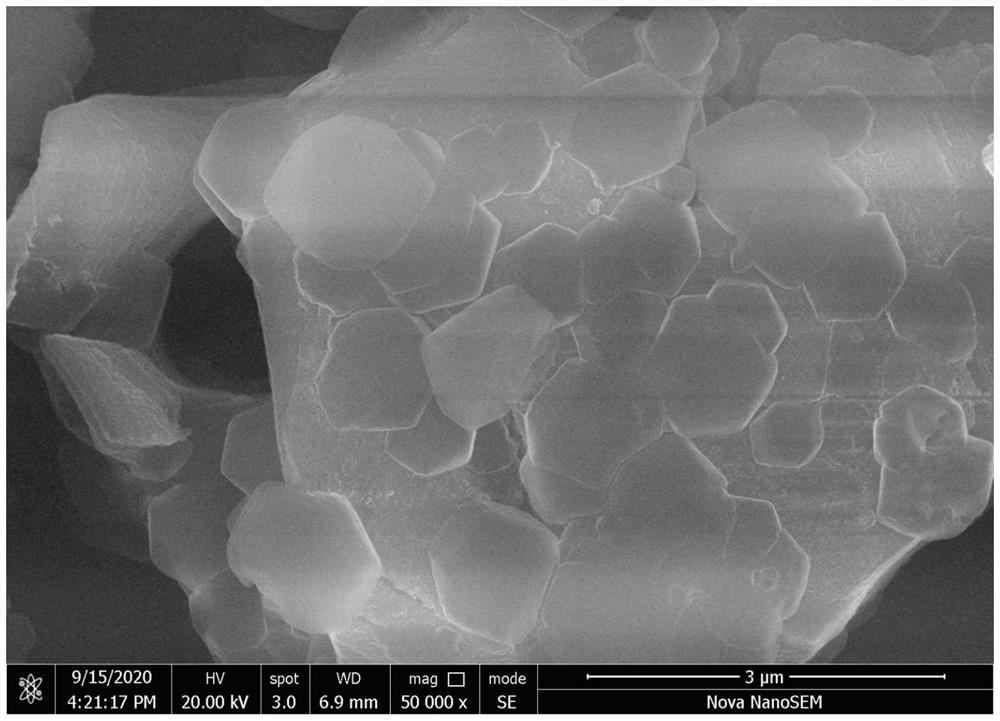

[0030] A. Take a clean plastic cup, add 30mL of 40% hydrofluoric acid solution, weigh 1g of MAX powder into the hydrofluoric acid solution, and stir for 24 hours until uniform. Then, the reacted product was centrifuged repeatedly, and the supernatant was washed with deionized water until the pH value was greater than 6. Finally, vacuum drying was carried out at 60°C for 10 hours, as figure 1 As shown, a SEM image with a layered structure was obtained. Additionally, by figure 2 The X-ray diffraction pattern of the prepared MXene powder can be obtained.

[0031] B. Take a clean beaker, add 20 mL of methanol solution, weigh 60 mg of MXene powder prepared in step A, and process it ultrasonically for 15 minutes to obtain MXene / methanol dispersion (3 mg / mL). 0.249 g Co(CH 3 COO) 2 4H 2 O was added to the MXene / methanol dispersion and ultrasonically dispersed for 1 h. Take anoth...

Embodiment 2

[0033] A preparation method of ZIF-67@MXene composite material, comprising the following steps:

[0034] A. Take a clean plastic cup, add 30mL of 40% hydrofluoric acid solution, weigh 1g of MAX powder into the hydrofluoric acid solution, and stir for 48 hours until uniform. Then, the reacted product was centrifuged repeatedly, and the supernatant was washed with deionized water until the pH value was greater than 6. Finally, a vacuum drying treatment was performed at 65° C. for 12 hours.

[0035] B. Take a clean beaker, add 20 mL of methanol solution, weigh 100 mg of MXene powder prepared in step A, and ultrasonically treat it for 15 minutes to obtain MXene / methanol dispersion (5 mg / mL). 0.249 g Co(CH 3 COO) 2 4H 2 O was added to the MXene / methanol dispersion and ultrasonically dispersed for 1 h. Take another clean beaker, add 20 mL of methanol solution, weigh 0.656 g of 2-methylimidazole, pour it into the methanol solution, and stir for 30 min. Finally, pour 20 mL of 2-...

Embodiment 3

[0037] A preparation method of ZIF-67@MXene composite material, comprising the following steps:

[0038] A. Take a clean plastic cup, add 30mL of 40% hydrofluoric acid solution, weigh 1g of MAX powder into the hydrofluoric acid solution, and stir for 36 hours until uniform. Then, the reacted product was centrifuged repeatedly, and the supernatant was washed with deionized water until the pH value was greater than 6. Finally, a vacuum drying treatment was performed at 70° C. for 14 hours.

[0039] B. Take a clean beaker, add 20 mL of methanol solution, weigh 80 mg of MXene powder prepared in step A, and process it ultrasonically for 15 minutes to obtain MXene / methanol dispersion (4 mg / mL). 0.291 g Co(NO 3 ) 2 ·6H 2O was added to the MXene / methanol dispersion and ultrasonically dispersed for 1 h. Take another clean beaker, add 20mL of methanol solution, weigh 0.492g of 2-methylimidazole, pour it into the methanol solution, and stir for 30min. Finally, 20 mL of 2-methylimid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com