Modified polyacrylonitrile for treating wastewater containing antimony and preparation method thereof

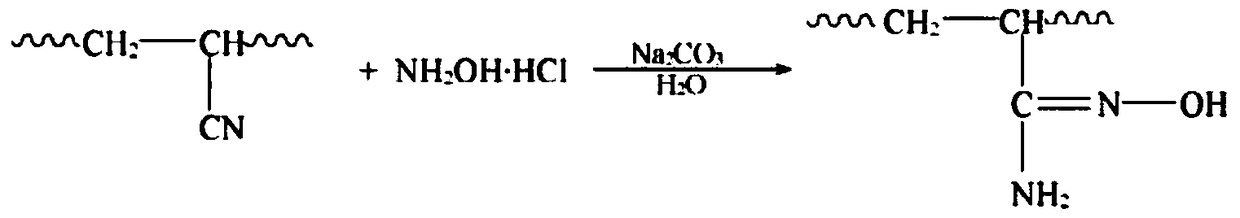

A polyacrylonitrile, polyacrylonitrile-based technology, applied in the field of modified polyacrylonitrile and its preparation, can solve the problems of limited oxime-based conversion rate, etc., and achieve the effects of good effect, abundant raw material sources and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh about 0.1g of PAN powder, immerse it in 100mL of 15g / L hydroxylamine hydrochloride aqueous solution, and add 1.10g of anhydrous sodium carbonate (the molar ratio of sodium carbonate and hydroxylamine hydrochloride is about 1:2), gently Stir to dissolve the sodium carbonate, and perform in-situ amidoximation in a water bath at 80°C.

[0034] (2) The reaction time is 4 hours, the product is taken out, soaked and washed with deionized water to remove sodium salt and unreacted hydroxylamine.

[0035] (3) The washed product was dried in an oven at 50° C. for 2 hours, dried in vacuum at 70° C. for 24 hours, and then taken out.

[0036] (4) The obtained product is ground into a granular adsorbent with a mesh number of 100 mesh.

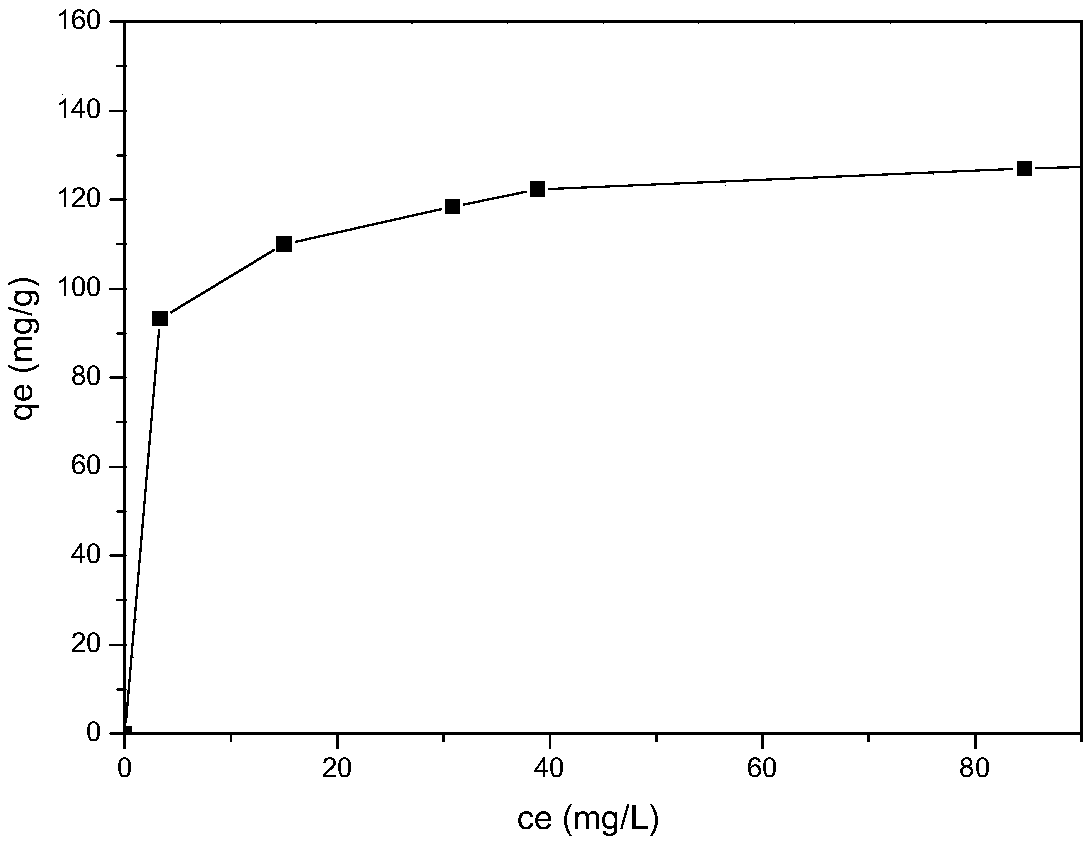

[0037] During the adsorption experiment, prepare 200 mL of antimony-containing simulated wastewater with initial concentrations of 10, 30, 50, 70, and 90 mg / L, respectively, and place them in 5 Erlenmeyer flasks, and then add 0.1 g of granu...

Embodiment 2

[0039] (1) Weigh about 0.1g of PAN powder, immerse it in 100mL of 15g / L hydroxylamine hydrochloride aqueous solution, and add 1.10g of anhydrous sodium carbonate (the molar ratio of sodium carbonate and hydroxylamine hydrochloride is about 1:2), gently Stir to dissolve the sodium carbonate, and perform in-situ amidoximation in a water bath at 80°C.

[0040] (2) The reaction time is 8 hours, the product is taken out, soaked and washed with deionized water to remove sodium salt and unreacted hydroxylamine.

[0041] (3) The washed product was dried in an oven at 50° C. for 2 hours, dried in vacuum at 70° C. for 24 hours, and then taken out.

[0042] (4) The obtained product is ground into a granular adsorbent with a mesh number of 100 mesh.

[0043] During the adsorption experiment, prepare 200 mL of antimony-containing simulated wastewater with initial concentrations of 10, 30, 50, 70, and 90 mg / L, respectively, and place them in 5 Erlenmeyer flasks, and then add 0.1 g of granu...

Embodiment 3

[0045] (1) Weigh about 0.1g of PAN powder, immerse it in 100mL of 15g / L hydroxylamine hydrochloride aqueous solution, and add 1.10g of anhydrous sodium carbonate (the molar ratio of sodium carbonate and hydroxylamine hydrochloride is about 1:2), gently Stir to dissolve the sodium carbonate, and perform in-situ amidoximation in a water bath at 60°C.

[0046] (2) The reaction time is 4 hours, the product is taken out, soaked and washed with deionized water to remove sodium salt and unreacted hydroxylamine.

[0047] (3) The washed product was dried in an oven at 50° C. for 2 hours, dried in vacuum at 70° C. for 24 hours, and then taken out.

[0048] (4) The obtained product is ground into a granular adsorbent with a mesh number of 100 mesh.

[0049]During the adsorption experiment, prepare 200 mL of antimony-containing simulated wastewater with initial concentrations of 10, 30, 50, 70, and 90 mg / L, respectively, and place them in 5 Erlenmeyer flasks, and then add 0.1 g of granul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com