Flame-retardant smoke-inhibition light-weight high-strength high-molecular material, and preparation method thereof

A polymer material and lightweight technology, applied in the field of lightweight materials, can solve problems such as the lack of research on the flame retardancy of gel emulsion systems, the impact on the environment and human health, and the immature foaming process. Temperature, water absorption is small, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the flame-retardant and smoke-suppressing lightweight high-strength polymer material of the present invention comprises:

[0044] 1. Preparation of soft template

[0045] Under normal temperature and pressure, add a certain amount of gelling agent, oil phase reactive monomer, oil phase crosslinking agent, initiator and composite flame retardant and smoke suppressant into a suitable container, stir and shake evenly, and then add the dispersed phase for emulsification , forming a uniform, fine, inverted gel emulsion that does not flow.

[0046] 2 Polymerization of soft templates

[0047] The gel emulsion in step 1 is thermally initiated and polymerized in a water bath. The polymerization process is as follows: after reacting at 30-90°C for 4-12 hours, it is dried in a constant temperature oven to obtain a flame-retardant and smoke-suppressing light-weight high-strength polymer material.

Embodiment 1

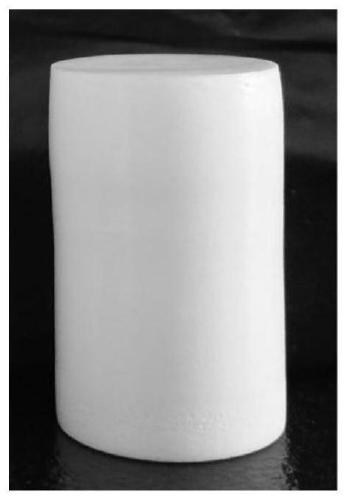

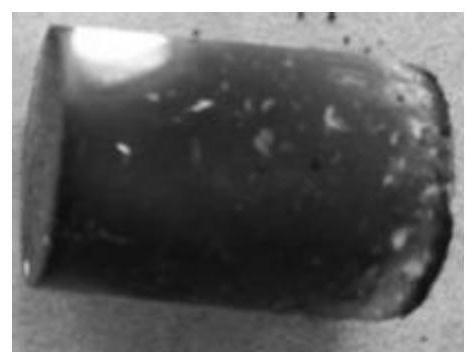

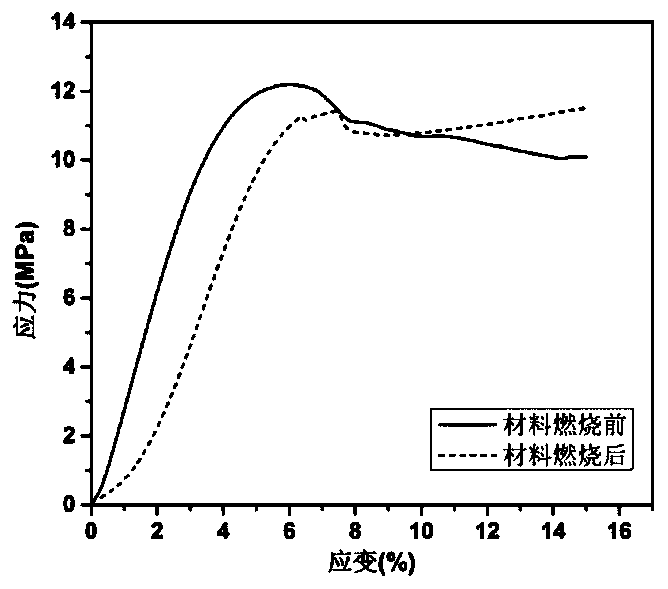

[0049] 3.7 mg dicholesterol derivatives, 550 μL styrene, 165 μL hexanediol diacrylate, 27.5 μL tripropenyl isocyanurate, 7.43 mg azobisisobutyronitrile, 148.5 mg triphenyl phosphate, 14.9 mg hydrogen Magnesium oxide and 59.4 mg of calcium phosphomolybdate were added to the test tube, shaken evenly on the shaker, and 5470 μL of water was added to shake on the vortex shaker to form a uniform milky white gel emulsion that was inverted and stagnant, and the test tube containing the gel emulsion Seal the mouth, react in a water bath at 90°C for 4 hours, and dry in a constant temperature oven at 100°C for 24 hours to obtain a density of 0.15±0.01g / cm 3 Lightweight high-strength flame-retardant polystyrene.

Embodiment 2

[0051] Add 242 mg of titanium dioxide micro-nanoparticles, 550 μL of styrene, 55 μL of pentaerythritol tetraacrylate, 30.25 mg of azobisisobutyronitrile, 60.5 mg of triphenyl phosphate, 60.5 mg of aluminum hydroxide and 12.1 mg of zinc borate into the test tube, and place on a shaker Shake evenly, add 5554 μ L of calcium chloride aqueous solution with a mass concentration of 2%, and shake on a vortex shaker to form a uniform, inverted and non-flowing milky white gel emulsion system, and seal the test tube mouth with the gel emulsion system. React in a water bath at 90°C for 12 hours, dry in a constant temperature oven at 100°C for 24 hours to obtain a density of 0.15±0.01g / cm 3 Lightweight high-strength flame-retardant polystyrene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com