Method for preparing ethylbenzene by reaction of dilute ethylene and benzene

A technology of diluting ethylene and ethylene, which is applied in the field of ethylbenzene production in petrochemical industry, can solve problems such as the increase of xylene content, and achieve the effect of reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1: Production example of 80,000 tons / year ethylbenzene plant

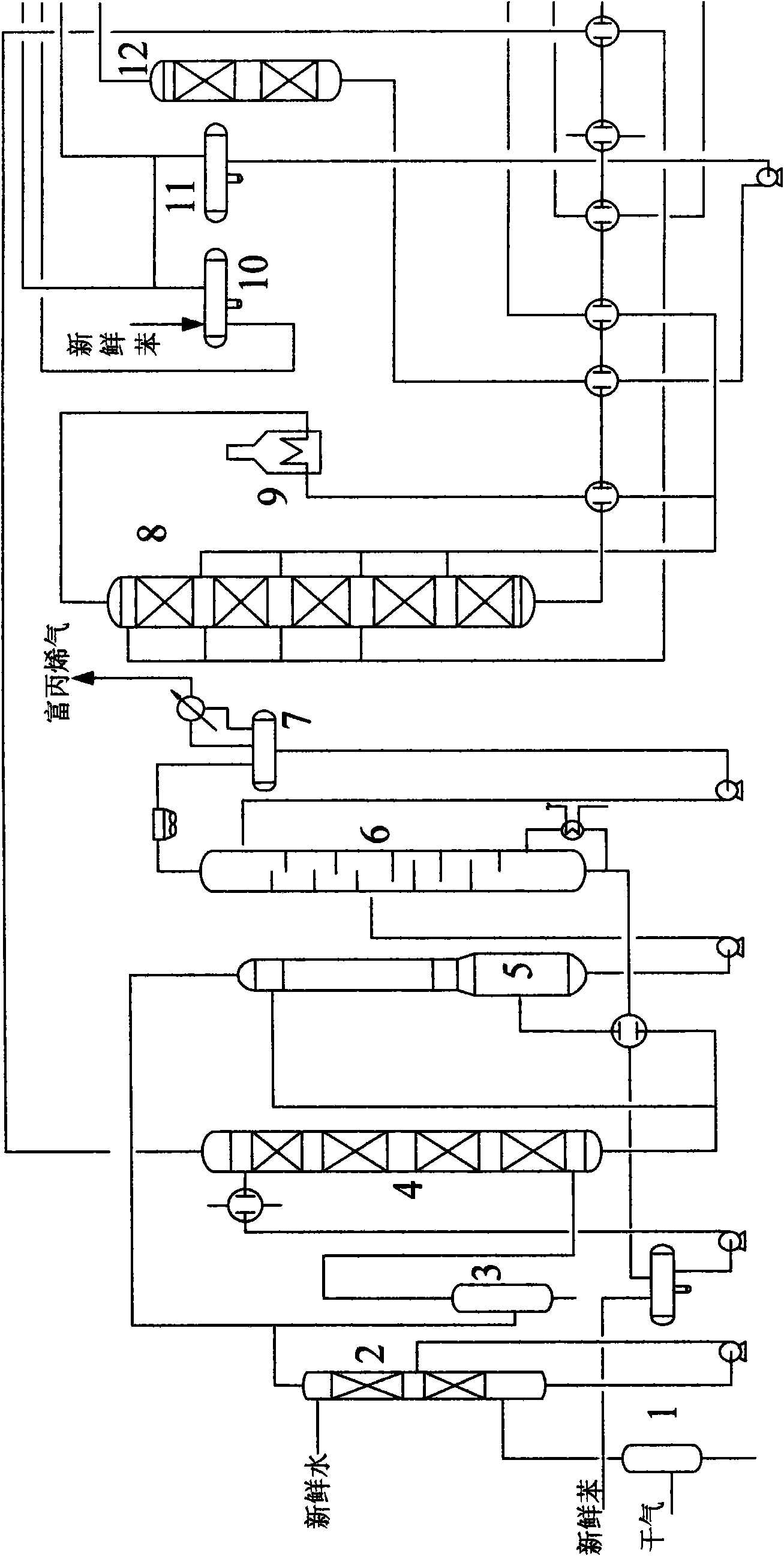

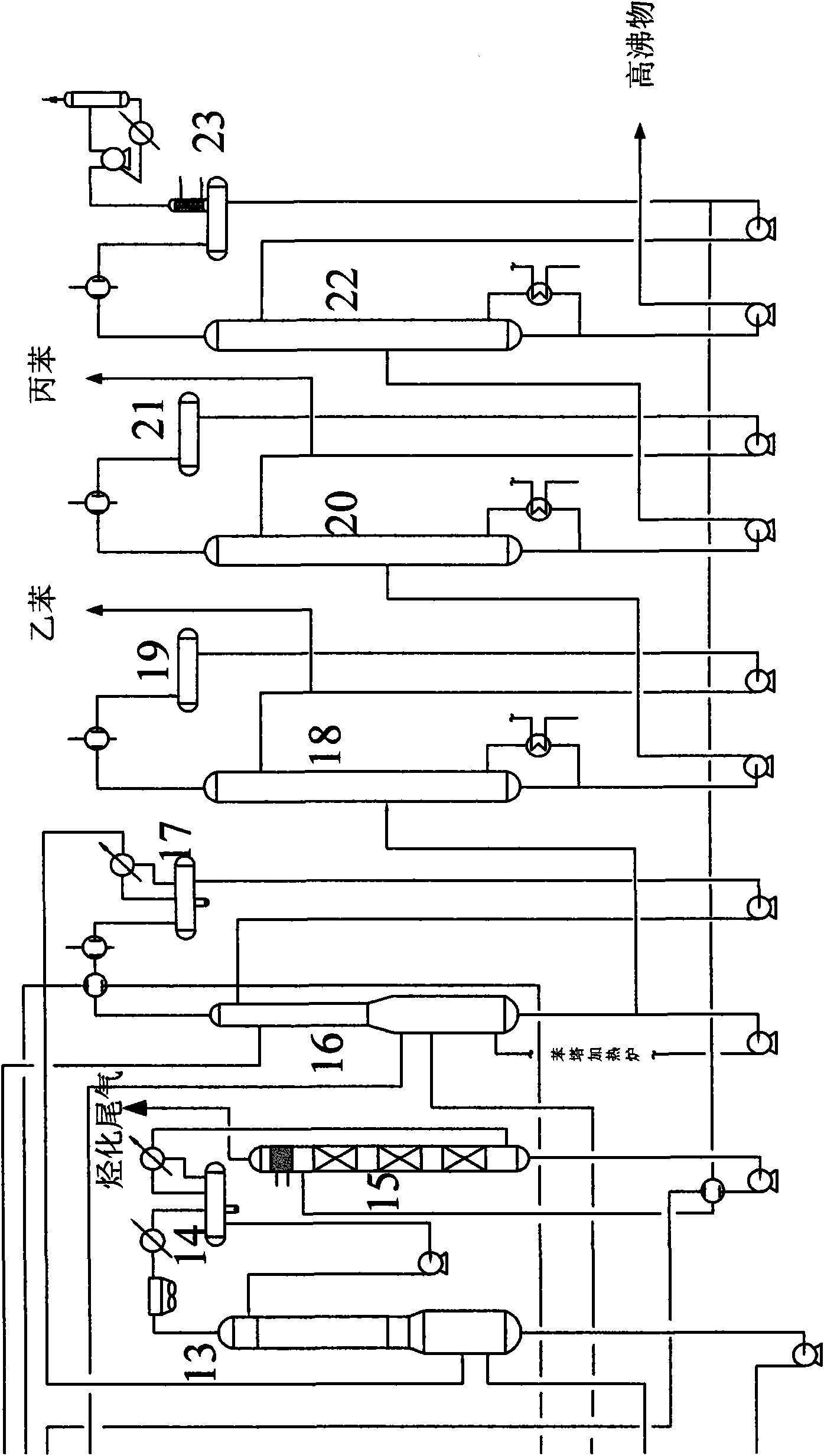

[0083] figure 1 , 2 The meanings of the equipment reference signs in the middle are as follows: dry gas liquid separation tank 1, water washing tower 2, liquid separation tank 3, propylene absorption tower 4, deethylene tower 5, depropylene tower 6, reflux tank 7, alkylation reactor 8, circulation Benzene heating furnace 9, circulating benzene buffer tank 10, anti-alkylation material tank 11, anti-alkylation reactor 12, rough fractionation tower 13, rough fractionation tower reflux tank 14, absorption tower 15, benzene tower 16, benzene tower reflux tank 17 , Ethylbenzene tower 18, ethylbenzene tower reflux tank 19, propylbenzene tower 20, benzene tower reflux tank 21, multiple ethylbenzene tower 22, ethylbenzene tower reflux tank 23.

[0084] ① Raw materials and reaction conditions: the main composition of dry gas is as follows (volume %): C 2 h 4 18.5, C 3 h 6 1.5, COx 3.6, O 2 0.4,H ...

Embodiment 2

[0096] Embodiment 2: Example of 80,000 tons / year ethylbenzene plant

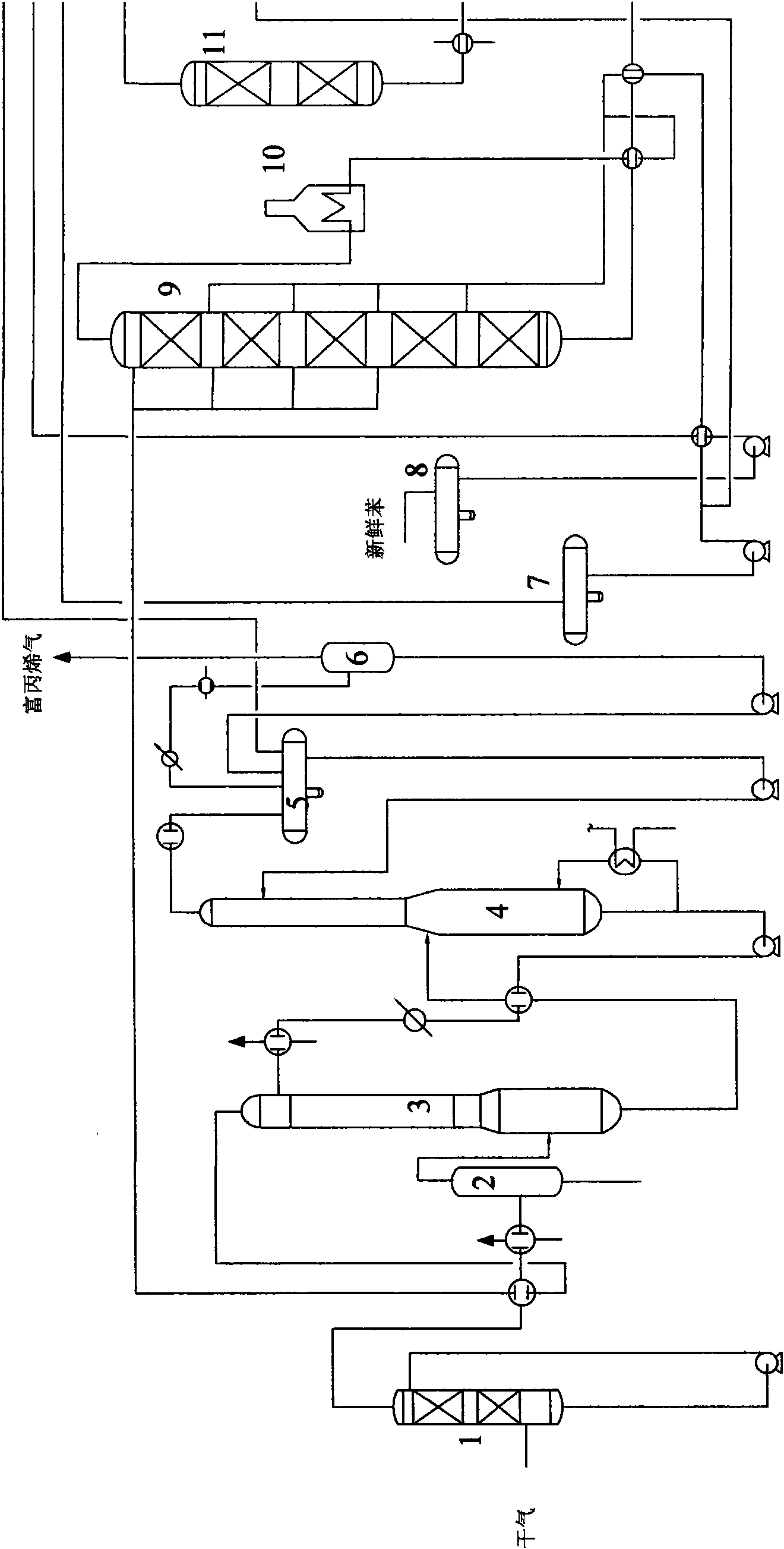

[0097] image 3 , 4 The meanings of reference signs in the middle are as follows: washing tank 1, liquid separation tank 2 / 6, propylene absorption tower 3, depropylene tower 4, reflux irrigation of each tower 5 / 15 / 17 / 19 / 21 / 23, circulating benzene tank 7, fresh Benzene tank 8, alkylation reactor 9, circulating benzene heating furnace 10, anti-alkylation reactor 11, tail gas absorption tower 13, benzene tower 14, non-aromatic tower 16, ethylbenzene tower 18, propylbenzene tower 20, polyethylen Benzene tower 22.

[0098] ① Raw materials and reaction conditions:

[0099] The dry gas composition is as follows (volume%): CH 4 30.5, C 2 h 4 25.5, C 2 h 6 15.6, C 3 h 6 4.3、C 3 h 8 2.5, H 2 8.4, N 2 7.5, CO 1.1, CO 2 4.0, O 2 0.6, H 2 S, 160mg / m 3 、H 2 O 1500ppm.

[0100] The alkylation catalyst adopts industrially produced DL0802 catalyst, the alkylation reaction conditions: reaction inlet...

Embodiment 3

[0127] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

[0128] The specific conditions of the alkylation reaction are: reaction temperature 280°C, reaction pressure 3.0MPa, molar ratio of benzene to ethylene is 2, and weight space velocity of ethylene is 2.5h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com