Supported noble metal catalyst and preparation and application thereof

A noble metal catalyst and supported technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydrocarbon production from carbon oxide, etc., can solve the problem of insufficient stability of noble metals, aggregation of nanoparticles, Catalyst deactivation and other problems, to achieve good practical application prospects, simple preparation process, good repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

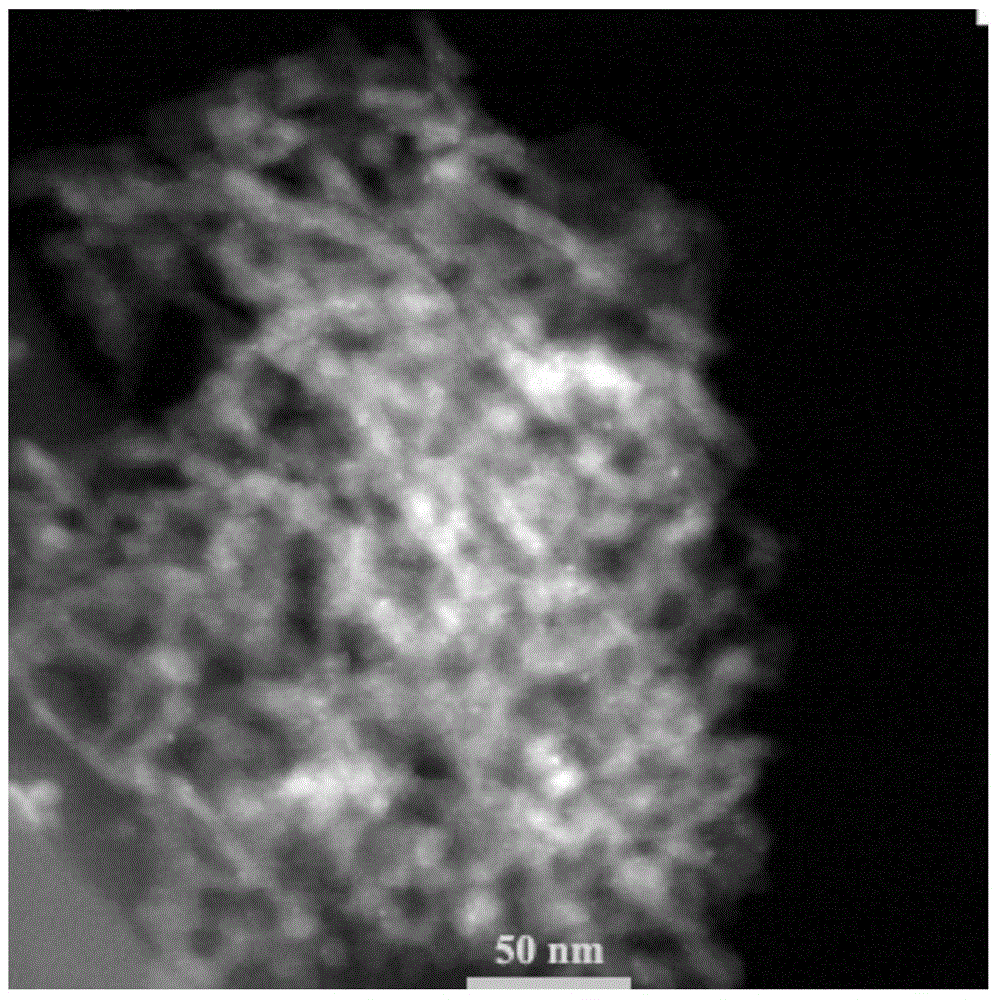

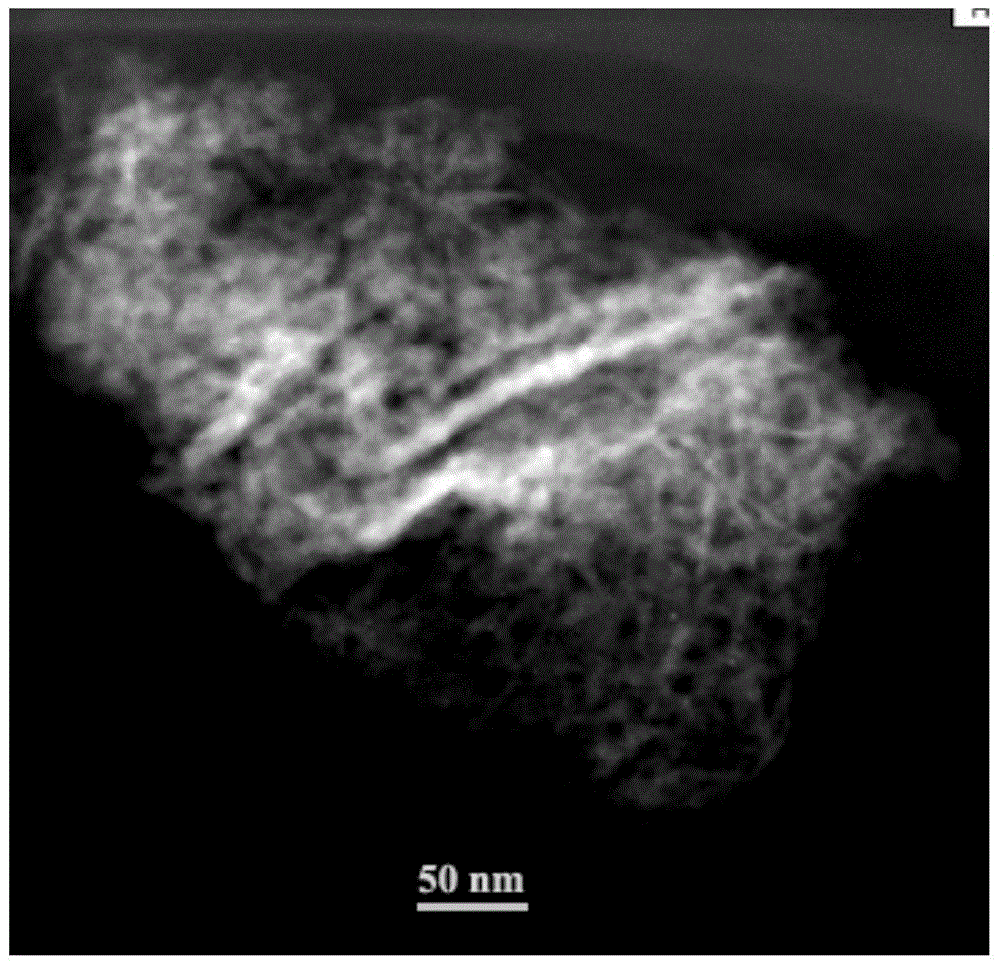

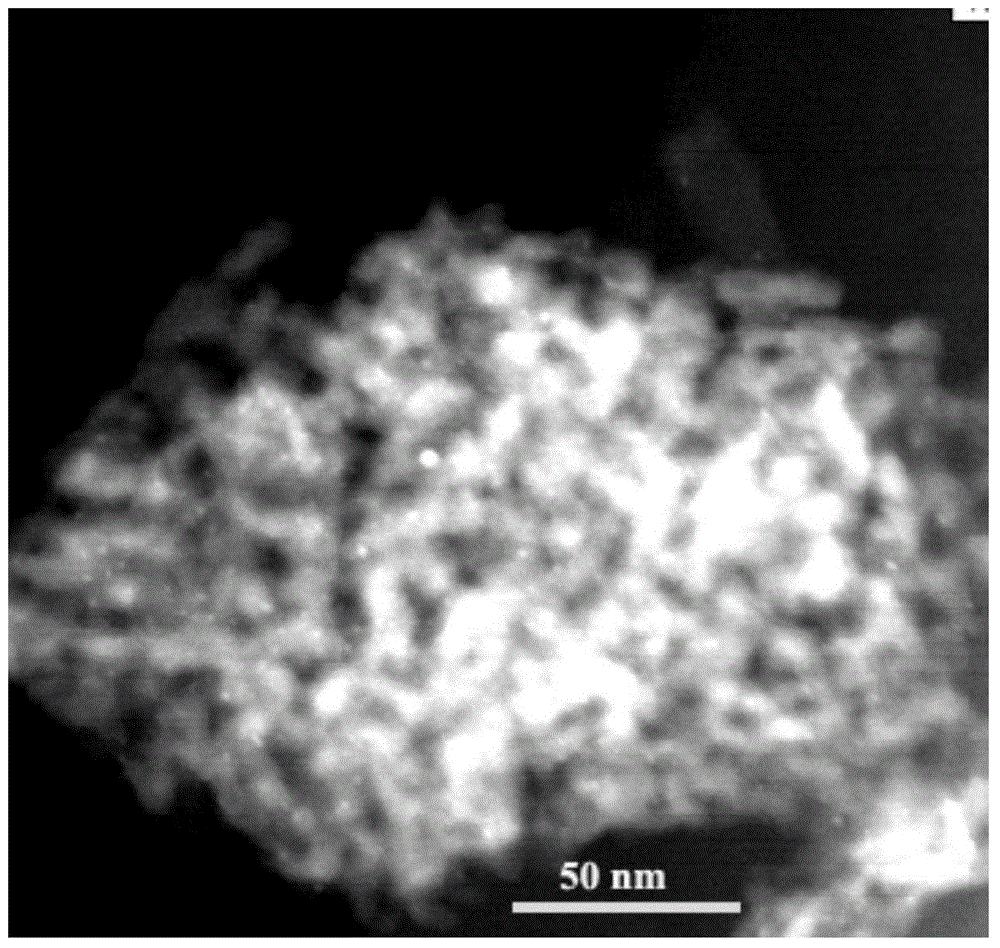

Image

Examples

Embodiment 1

[0030] 1. 5% La 2 o 3 -Al 2 o 3 Preparation of composite carrier:

[0031] Immersion method: Weigh 0.2798g La(NO 3 ) 3 .6H 2 O is fully dissolved in 3.0ml deionized water and poured into 2.0001g Al 2 o 3 Carrier, stirred evenly, let stand for 2h, then dried at 110°C for 10h, and finally roasted at 650°C for 2h to obtain 5wt.%La 2 o 3 -Al 2 o 3 Composite carrier;

[0032] Co-precipitation method: Weigh 0.2798g La(NO 3 ) 3 .6H 2 O and 2.3670g AlCl 3 .6H 2 O was dissolved in 6.3mL deionized water to make a mixed solution. Under stirring conditions, NaOH solution (2mol / L) was added dropwise until the pH of the La and Al mixed solution was 7. After the dripping, continue to stir for 2h and stand for aging for 6h, then filter Washed with water, dried at 120°C for 12h, and calcined at 650°C for 2h to obtain 5wt.% La 2 o 3 / Al 2 o 3 Composite carrier.

[0033] 2. 5%Ru / 5%La 2 o 3 -Al 2 o 3 Catalyst preparation:

[0034] Immersion method: Measure RuCl 3 Solut...

Embodiment 2

[0037] 1. 10%TiO 2 -Al 2 o 3 Preparation of:

[0038] Immersion method: measure TiCl 4 Solution (0.91mol / L, containing HCl concentration 2mol / L) 1.53mL into a beaker, start stirring in a water bath at 50°C, add NH 3 ·H 2 O solution (1mol / L) to pH=4, then pour 2.001g Al 2 o 3 Carrier, continue to stir for 8 hours and then stand still for 12 hours. After filtering, bake the carrier at 150°C for 12 hours, and roast at 800°C for 4 hours to obtain rutile TiO 2 Modified 10%TiO 2 / Al 2 o 3 Composite carrier;

[0039] Co-precipitation method: weigh 2.3670g AlCl 3 .6H 2 O to the beaker, and measure and add TiCl 4 Solution (0.91mol / L, containing HCl concentration 2mol / L) 1.53mL, start stirring in a water bath at 50°C, add NH 3 ·H 2 O solution (2mol / L) to pH = 7, continue to stir for 4 hours and then let it stand for 8 hours. After filtering, the composite carrier precursor is baked at 150 °C for 12 hours, and roasted at 800 °C for 4 hours to obtain rutile TiO 2 Modified ...

Embodiment 3

[0044] 1. 15%LaAlO 3 -Al 2 o 3 Preparation of:

[0045] Immersion method: Weigh 0.8025g La(NO 3 ) 3 .6H 2 O was fully dissolved in 2.9ml deionized water and poured into 2.0008g Al 2 o 3 Carrier, stir evenly, let stand for 8h, then dry at 120°C for 10h, and finally roast at 900°C for 6h to obtain 15wt.%LaAlO 3 -Al 2 o 3 Composite carrier;

[0046] Co-precipitation method: Weigh 0.8025g La(NO 3 ) 3 .6H 2 O and 8.772g Al(NO 3 ) 3 .9H 2 O was dissolved in 20mL deionized water, and 3mol / L KOH solution was added dropwise with stirring until pH = 7. After dropping, continued to stir for 4h and aged for 8h, filtered and washed, dried at 120°C for 10h, and calcined at 900°C for 6h to obtain 15wt.%LaAlO 3 -Al 2 o 3 Composite carrier.

[0047] 2. 10%Ru / 15%LaAlO 3 -Al 2 o 3 Preparation of:

[0048] Immersion method: Measure RuCl 3 Solution (30.91g Ru / L) 3.59mL, in a water bath at 50°C, NaOH solution (2mol / L) was added dropwise to pH=4, and 1.0005g15%LaAlO 3 -Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com