Technology for preparing organic fuel through directly converting carbon dioxide by using sunlight and photothermal catalyst

A carbon dioxide and organic fuel technology, applied in solar energy and its application fields, can solve the problems of low efficiency of photocatalytic process, high energy consumption and high production cost of thermal catalytic process, and achieve increased sunlight absorption, high reactivity and stability, Improve the effect of light energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

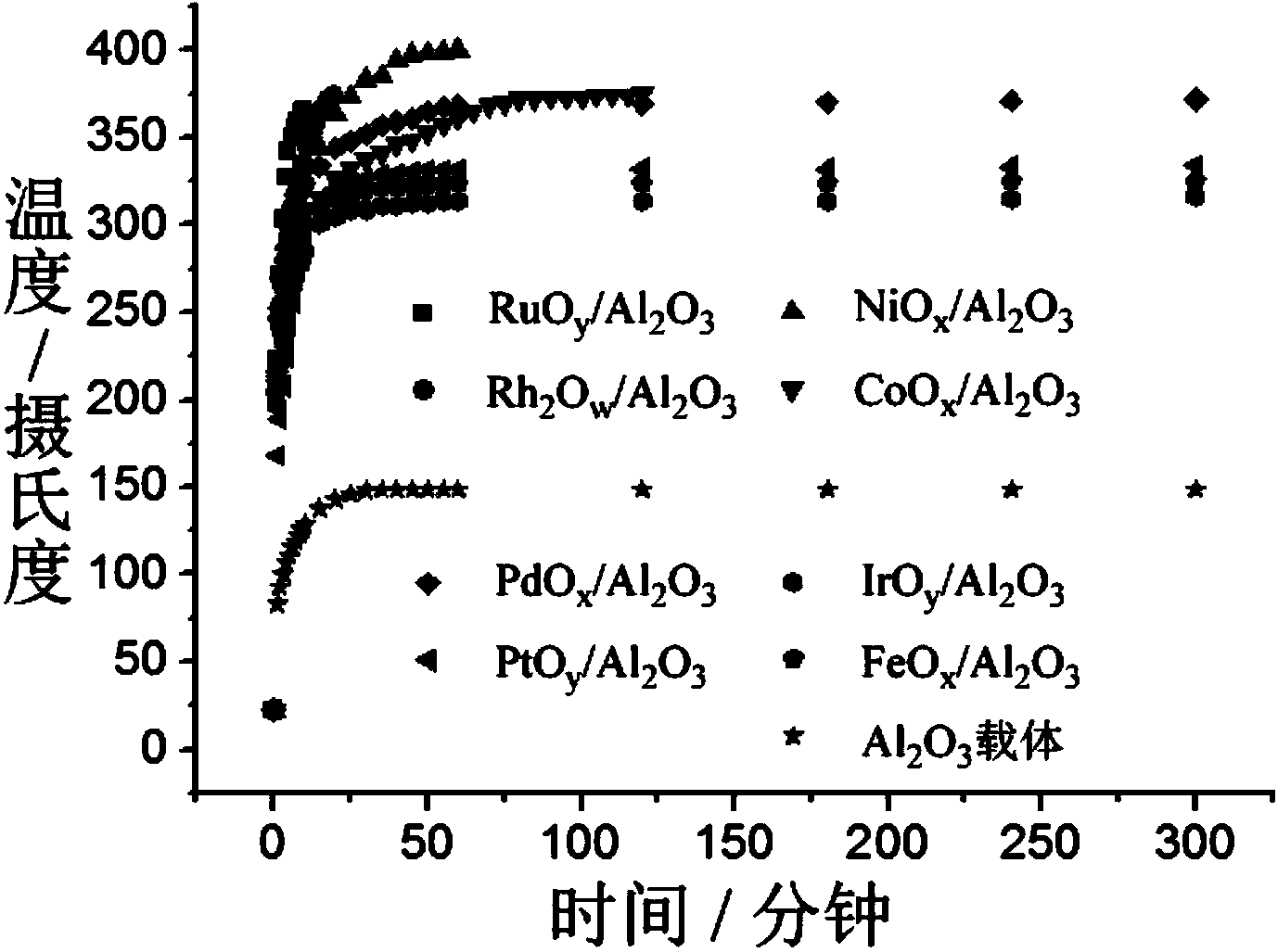

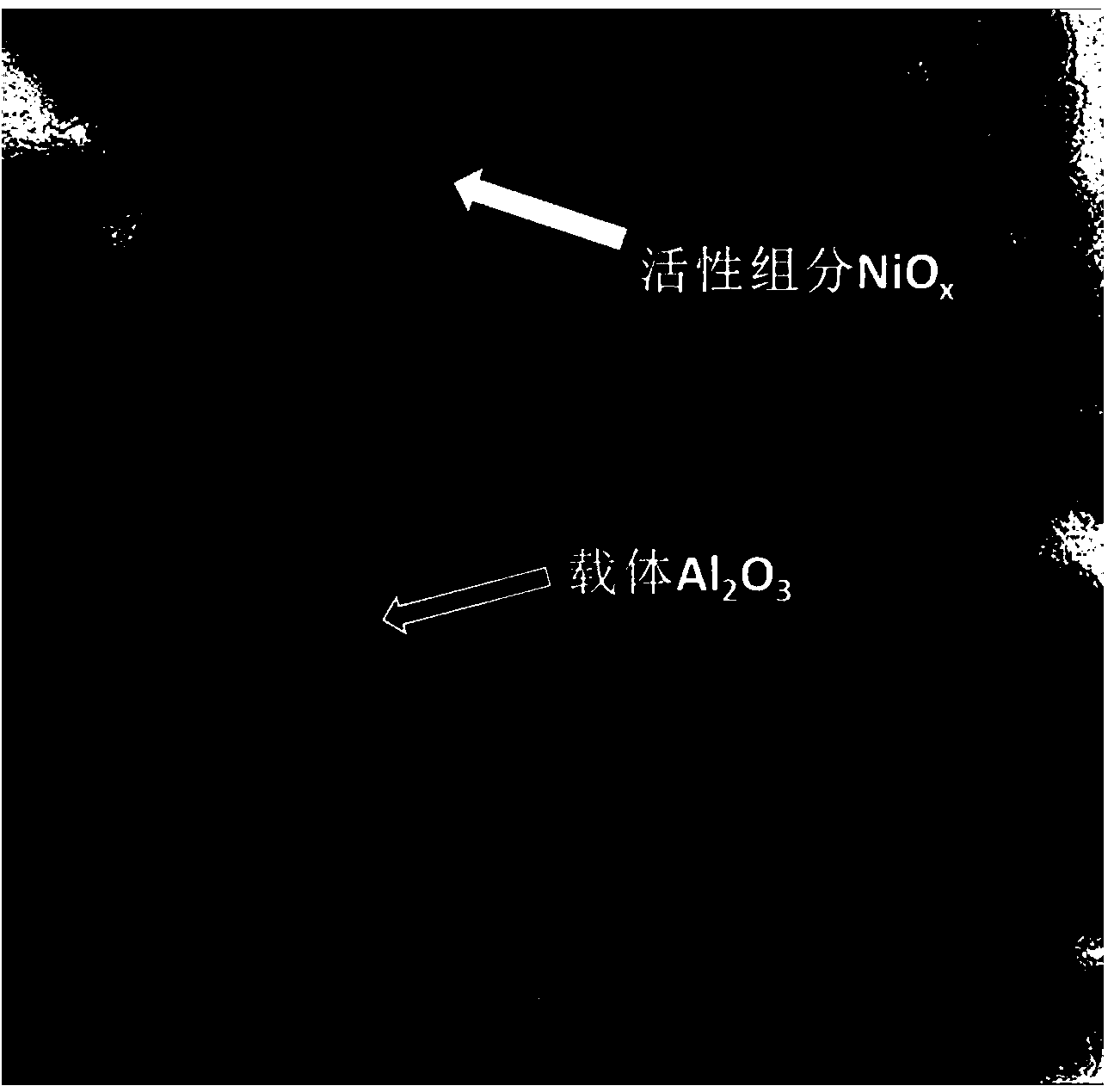

[0031] Elements of transition group VIII supported on activated Al 2 o 3 Supported photothermal catalysts and their photothermal catalytic conversion of carbon dioxide:

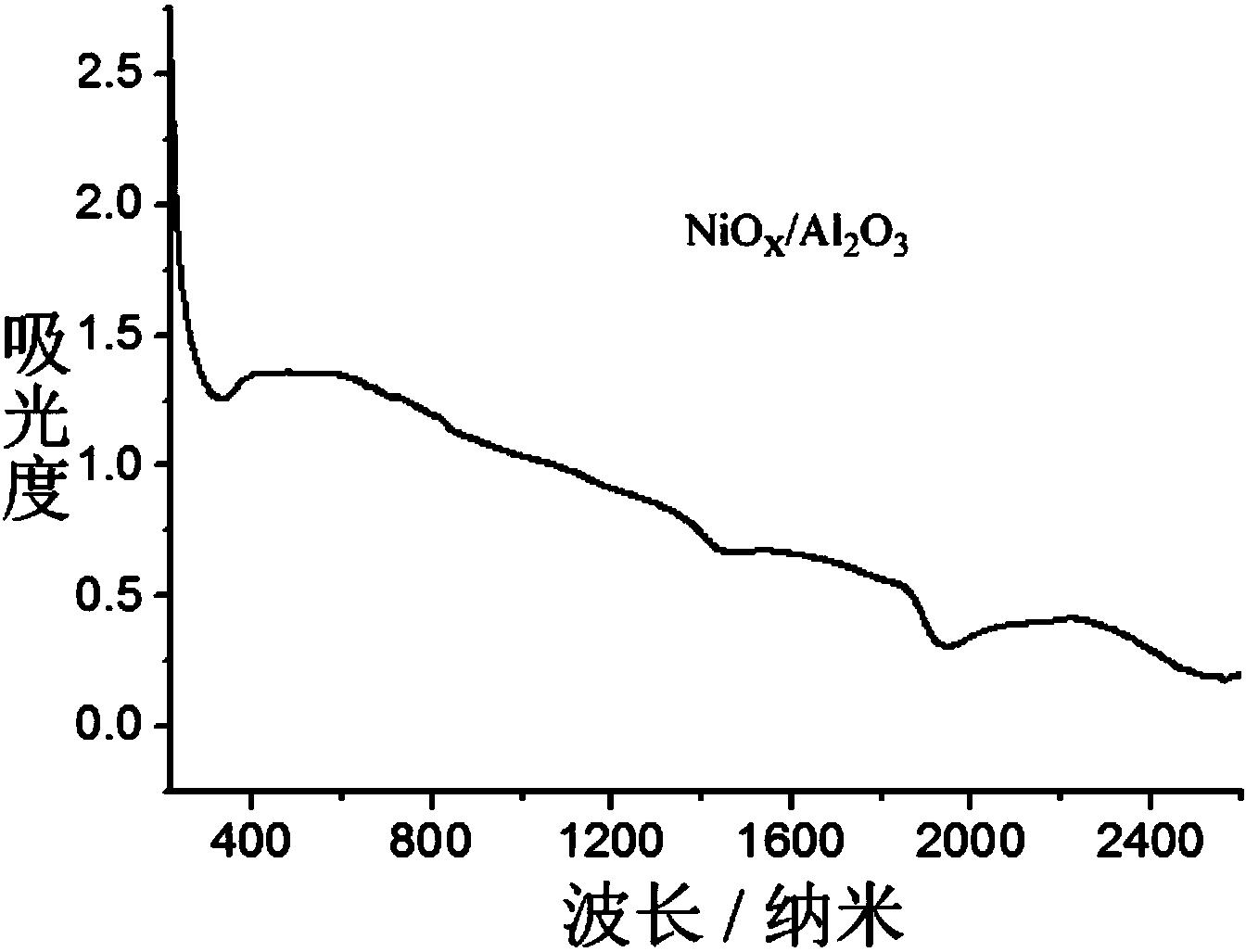

[0032] Weigh 1.0 g of alkaline carrier to activate Al 2 o 3 , take the prepared Ni(NO 3 ) 2 solution, mix the two in a mortar and grind them evenly, place the mortar under converging simulated sunlight (10 times the light intensity of AM1.5) and irradiate the sample until the sample is completely dry, and grind the sample carefully. Weigh 0.3 g of ground powder and put it into a photothermal catalytic reactor, pass it into an air atmosphere (flow rate, 10 ml / min), and use convergent simulated sunlight (light intensity is 15 times that of AM1.5) to heat the powder , the temperature is about 300 degrees Celsius, keep it for 2 hours; change the atmosphere to a mixed gas of hydrogen and carbon dioxide (volume ratio, 4.2:1.0; flow rate, 25 ml / min), because the carbon dioxide methanation reaction is a strong e...

Embodiment 2

[0040] Ni element supported on nano-SiO 2 Carrier photothermal catalyst and load control:

[0041] Weigh five 0.5 g portions of alkaline-modified nano-SiO 2 Carrier, take the prepared Ni (NO 3 ) 2 solution, the nano-SiO 2 The carrier and five solutions were mixed in five beakers respectively, a certain volume of water was added to increase the solution volume to 20 ml, and the beakers were ultrasonically treated for 10 minutes to disperse the carrier material evenly. The treated solution was placed on a mixing table and stirred, and the solution was heated by converging simulated sunlight (12 times the light intensity of AM1.5) until it was completely evaporated to dryness, and then the powder was transferred to a mortar for careful grinding. Take by weighing 0.3 gram of this powder and pack it into a photothermal catalytic reactor, pass into the air atmosphere (flow rate, 10 ml / min), utilize the converging simulated sunlight (light intensity is 15 times of AM1.5) to heat ...

Embodiment 3

[0045] Preparation of Ru elements supported on MgO, CaO, ZrO by solar energy 2 , La 2 o 3 Supported photothermal catalyst:

[0046] Take by weighing 1.0 grams of basic carrier MgO, measure the prepared Ru according to the mass percentage of Ru metal of 2.5% 3 (CO) 12 solution, mix the carrier material with the solution in a beaker, add a certain volume of water to increase the volume of the solution to 20 ml, and ultrasonically treat the beaker for 10 minutes to disperse the carrier material evenly. The treated solution was placed on a mixing table and stirred, and the solution was heated by converging simulated sunlight (10 times the light intensity of AM1.5) until it was completely evaporated to dryness, and then the powder was transferred to a mortar for careful grinding. Take by weighing 0.3 gram of this powder and pack it into a photothermal catalytic reactor, pass into the air atmosphere (flow rate, 10 ml / min), utilize the converging simulated sunlight (light intensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com