System for recovering residual heat of ammonia vapor on top of surplus ammonia water ammonia still

An ammonia distillation tower and ammonia steam technology, which is applied in the field of ammonia steam waste heat recovery system at the top of the residual ammonia distillation tower, can solve the problems of reducing energy utilization rate, increasing process water consumption, waste and the like, achieving good economic and social benefits, The effect of promoting a wide range of applications and a small amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

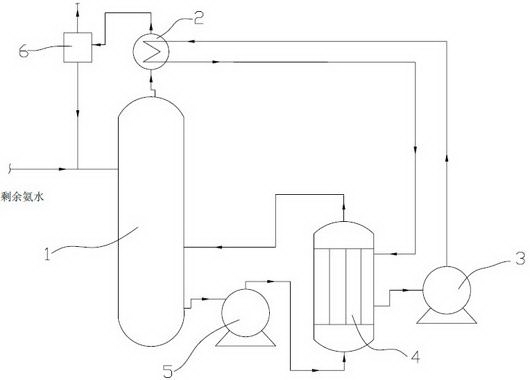

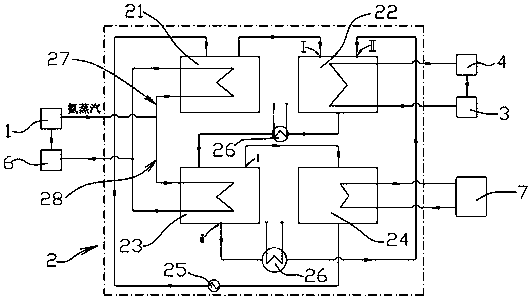

[0019] Such as figure 1 with figure 2 As shown, a waste heat recovery system for ammonia vapor at the top of the residual ammonia distillation tower includes an ammonia distillation tower 1, a heat pump unit 2, a circulating hot water pump 3, a reboiler 4, a waste water pump 5 and a gas-liquid separator 6. The heat pump unit 2 is a (type II) absorption heat pump unit, including an evaporator end 21 , an absorber end 22 , a generator end 23 and a condenser end 24 .

[0020] Ammonia distillation tower 1 has an input port for remaining ammonia water and an outlet for ammonia vapor, and a heating unit is provided at the bottom of ammonia distillation tower 1, through which the remaining ammonia water fed into ammonia distillation tower 1 is effectively evaporated to gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com