Method for conveying ceramic powder to mould and distributing mechanism

A technology for ceramic powder and mold, applied in the field of ceramic tile production equipment, can solve the problems of occupying pressing cycle time, reducing production speed, low single-machine output, etc., and achieves stable and fast distribution. The effect of reducing the difficulty and cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

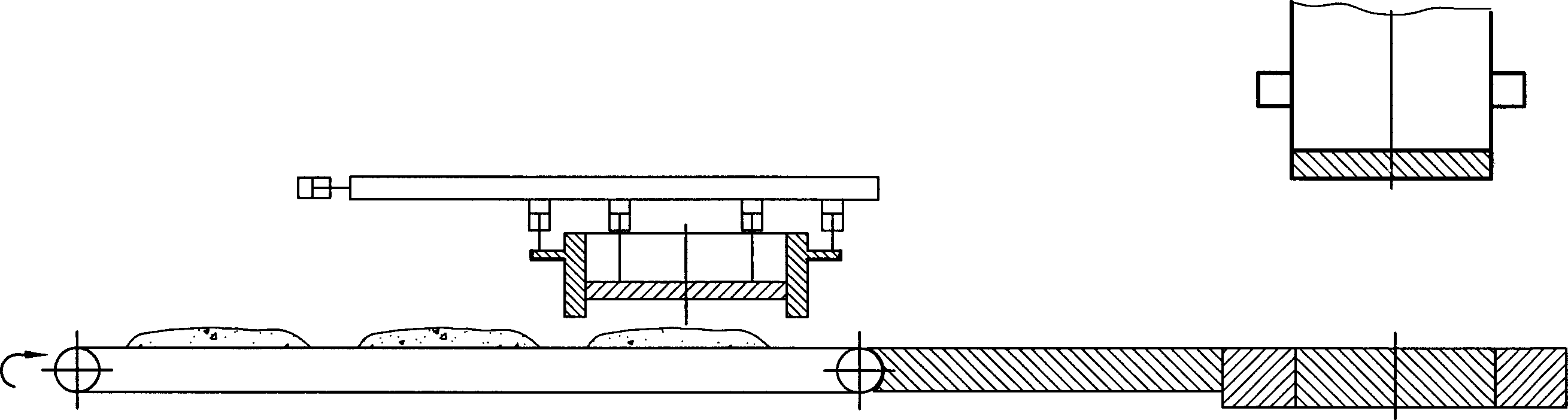

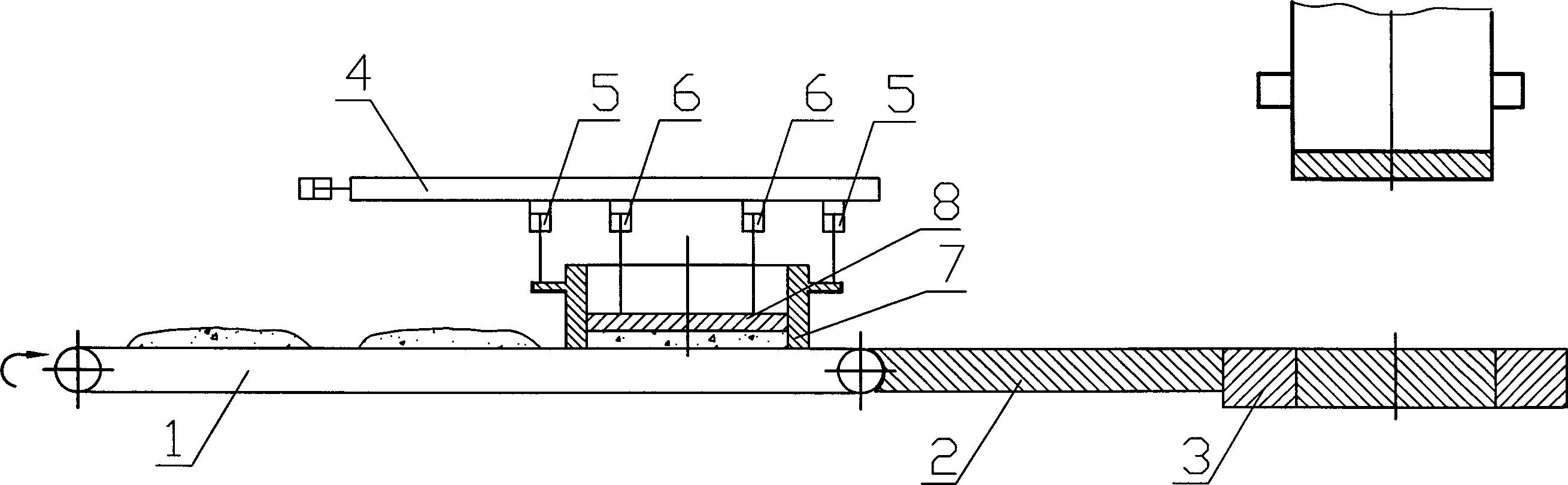

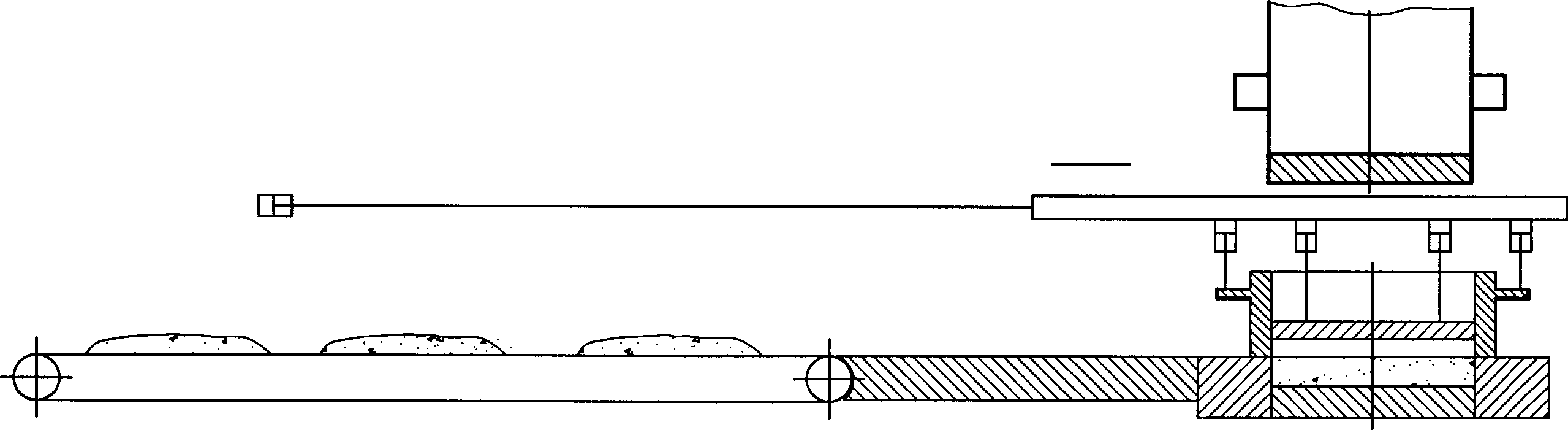

[0026] Such as Figure 1 to Figure 5 As shown, the cloth mechanism of the present invention has a flat conveyor belt 1 that can be rotated intermittently in a loop type. A connecting plate 2 is provided between the flat conveyor belt 1 and the mold 3. The upper surface of the flat conveyor belt and the upper surface of the connecting plate are at the same level to form a flat conveying platform. The upper surface of the flat conveying platform and the upper surface of the mold frame The plane is on the same horizontal plane, and one side of the connecting plate matches the arc of the flat conveyor belt outlet to achieve close contact, and the opposite side is in close contact with the mold frame. A pre-compression setting device is provided above the flat conveyor belt 1 near the exit. It includes a horizontal pushing mechanism 4, a vertical moving mechanism 5 and a semi-sealed frame body 7. A movable plate 8 is built above the semi-sealed frame body 7, and the movable plate 8 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com