Brick-making machine cloth mechanism with material stirring mechanism

A technology of brick making machine and cloth, which is applied in the direction of manufacturing tools, clay preparation equipment, cement mixing equipment, etc., can solve the problems of poor rigidity, fracture, and bending of the stirring rod, and achieve rigidity, not easy to damage, and fast cloth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Best embodiment:

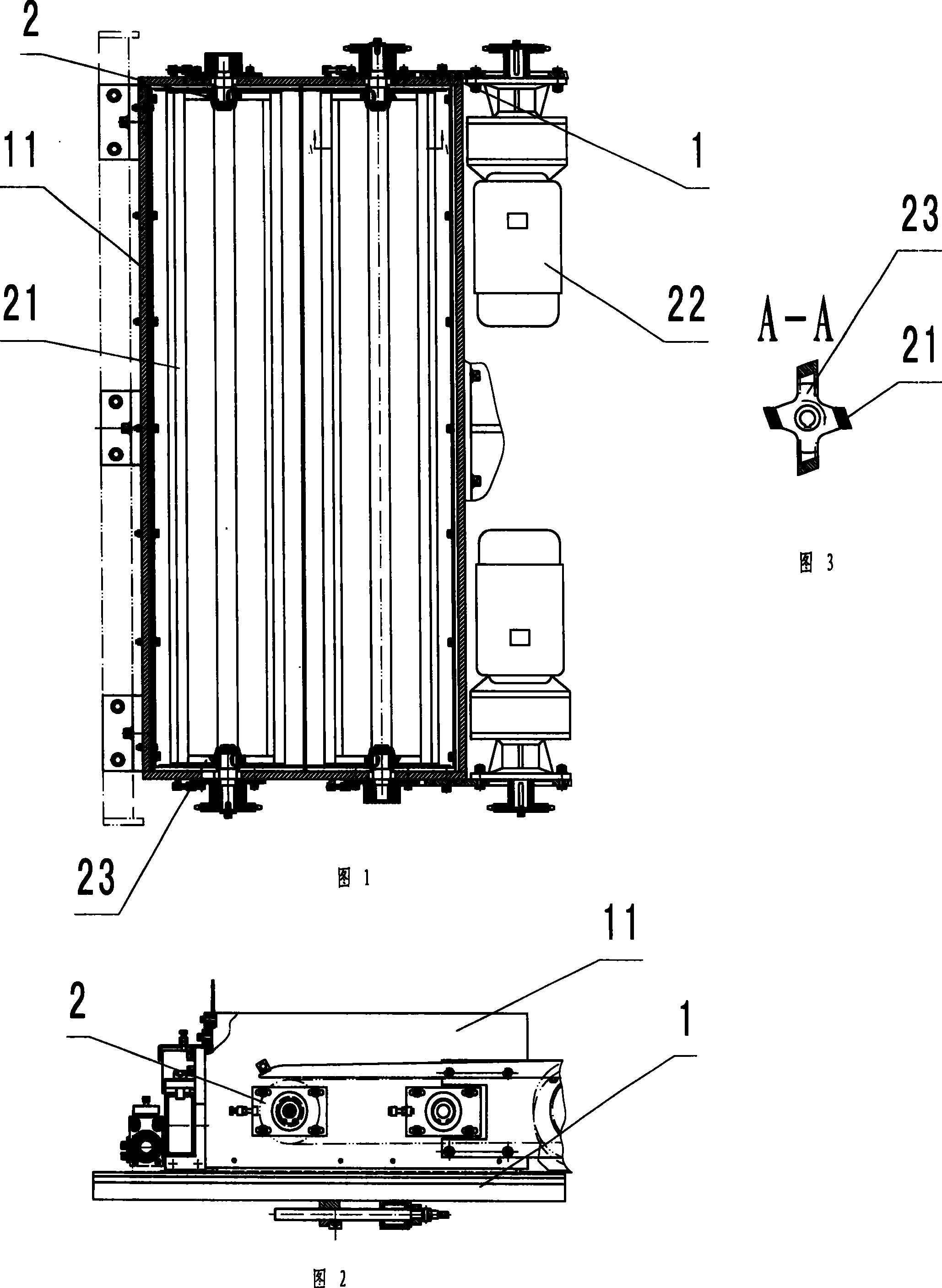

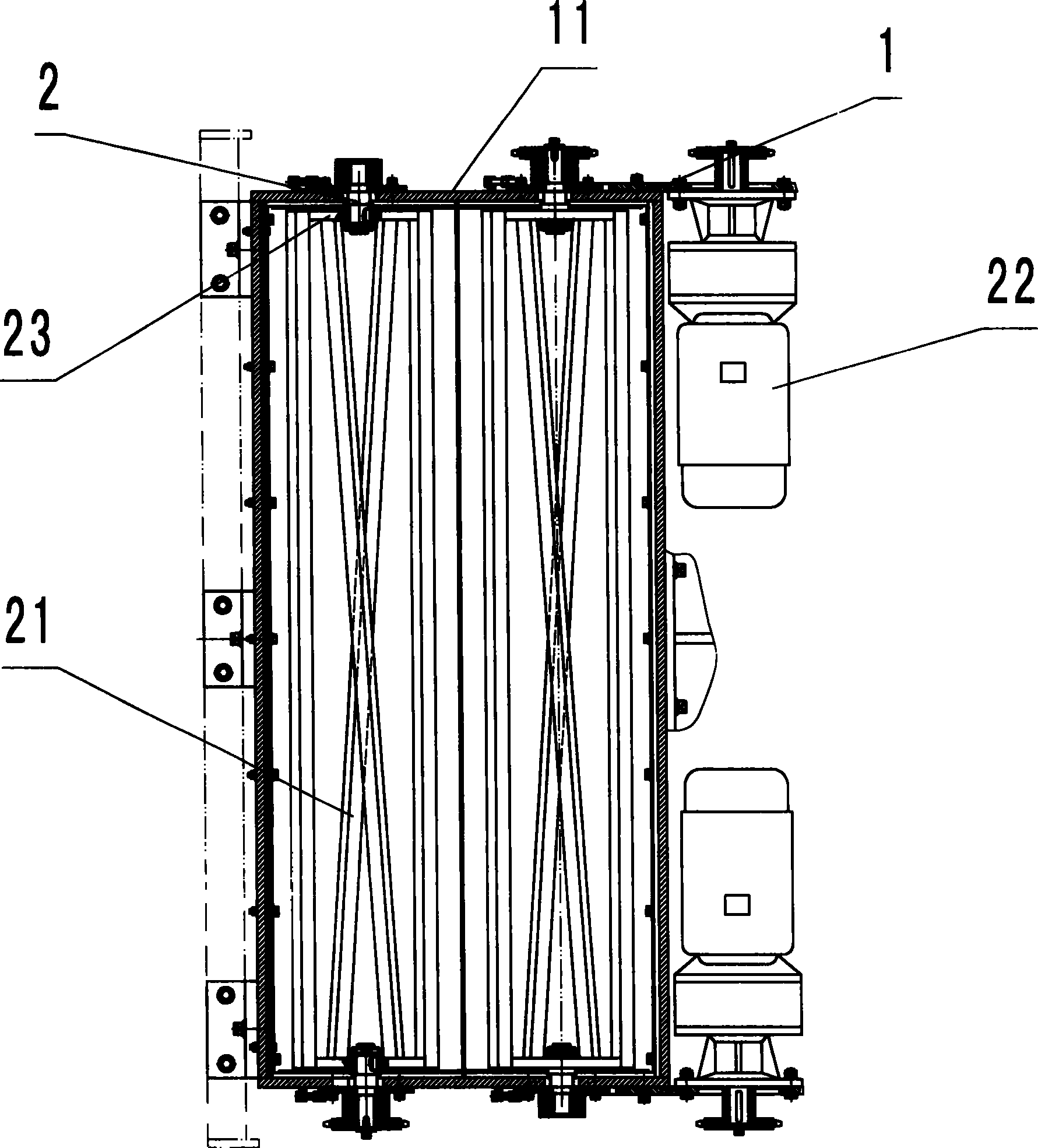

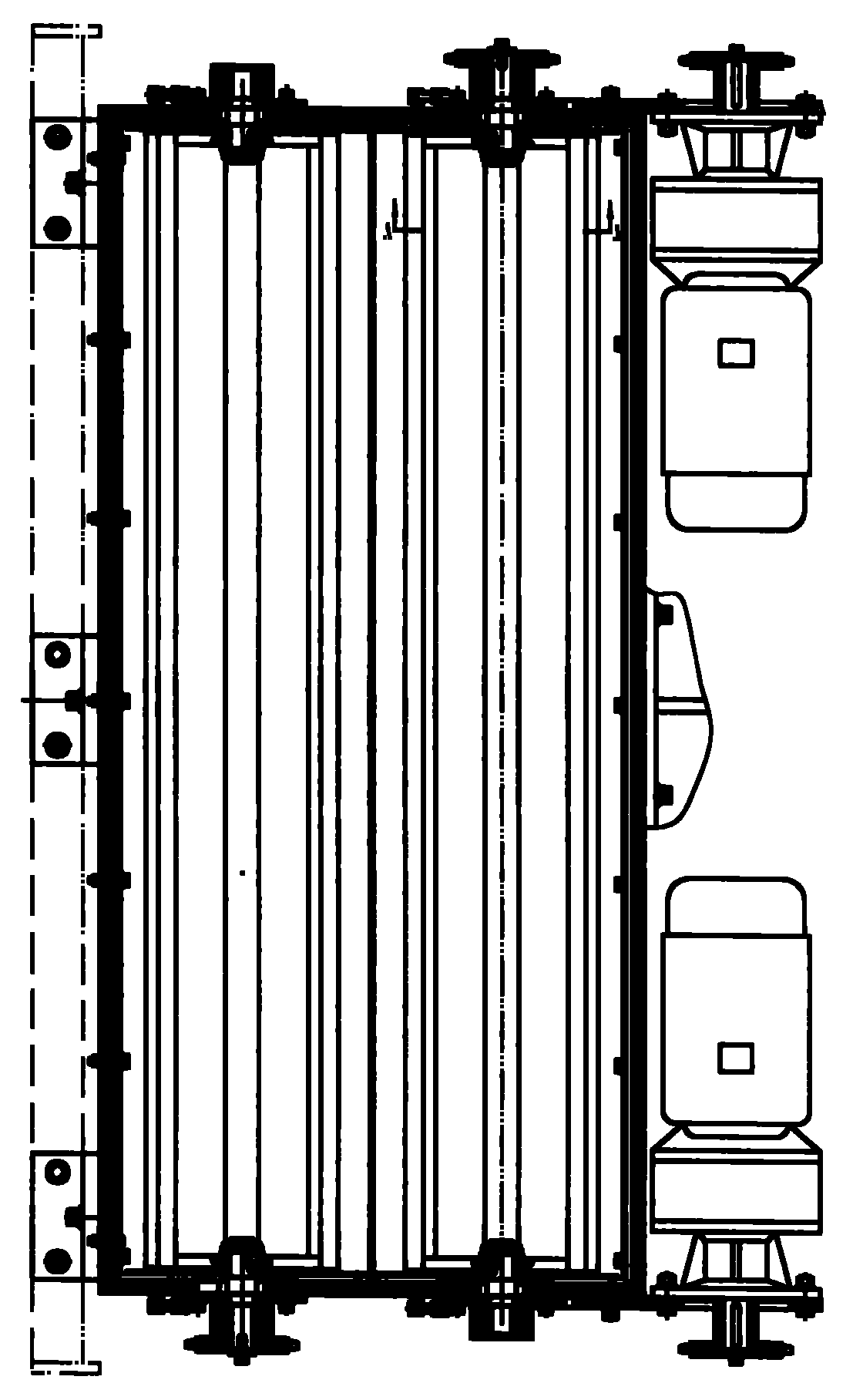

[0025] Reference figure 1 , figure 2 , image 3 , The distributing mechanism of the brick making machine with a stirring mechanism includes a distributing cart 1 and a distributing mechanism 2. The distributing cart 1 has a material frame 11, and the distributing mechanism 2 includes a plurality of agitating shafts 21 and a power mechanism 22. The two ends are respectively fixed on the rotating member 23. After the rotating member 23 is rotated, each stirring shaft 21 rotates to form a column, and the rotating members 23 at both ends of the stirring shaft 21 are respectively supported on the material frames 11 on both sides, and the power mechanism 22 Drive connection with the rotating member 23. The rotating part 23 is in the shape of a cross and has four stirring shafts 21, the two ends of which are respectively fixed to the ends of the forks and are parallel to each other, so that the stirring shaft 21 rotates to form a cylindrical shaft with a polyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com