Distributing device for delivering concrete of connected concrete bunkers

A technology of distributing device and cement silo, which is applied in the field of distributing device of cement storage conjoined silo in a cement factory, can solve the problems of difficulty in distributing slip-form concrete in the silo, low concrete construction efficiency, disordered slip-form platform, etc. Construction quality, low production cost, simple production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

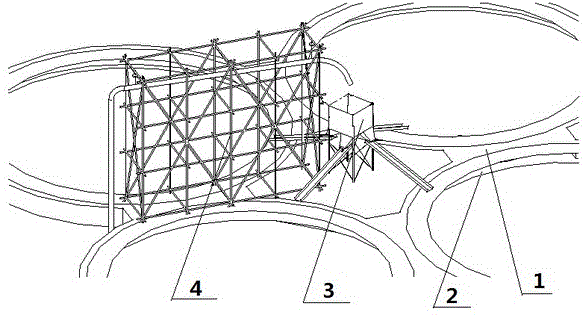

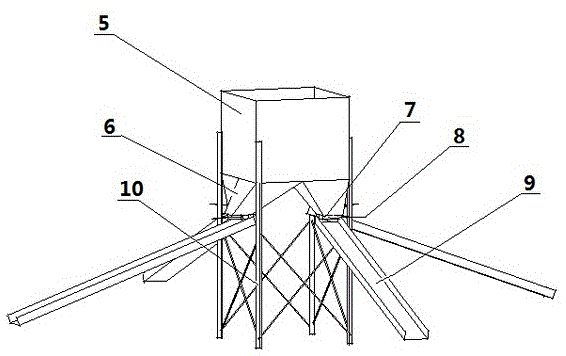

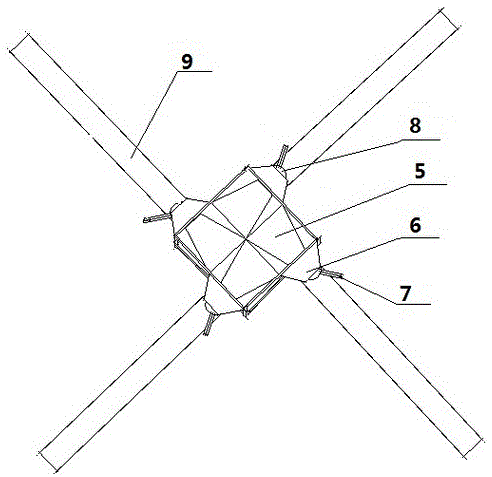

[0014] In the figure, the distributing device for the concrete delivery of the conjoined cement silo of the present invention is mainly composed of a slipform cement silo platform 1, a silo wall 2, an aggregate distributor 3, a pump tube horizontally adjustable fixing frame 4, and a cavity cuboid 5. , Trapezoidal distribution port 6, circular welded pipe 7, discharge switch 8, conveying slide 9, bracket 10, chain hoist 11, pump tube 12, double-row fixing frame 13 and base 14.

[0015] The aggregate distributor 3 and the horizontally adjustable fixing frame 4 of the pump tube are fixed on the platform surface of the slipform cement storage platform 1;

[0016] The collection distributor 3 includes a cavity cuboid 5, a trapezoidal distribution port 6, a circular welded pipe 7, a discharge switch 8, a conveying slide 9 and a support 10, and the cavity cuboid 5 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com