A continuous automatic cement distributing device and method

An automatic cloth and cloth device technology, applied in the field of machinery, can solve the problems of easily damaged insulation cotton, inability to effectively control quality, and low efficiency of manual operation, and achieve the effect of fast speed, easy control of plastering quality, and automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

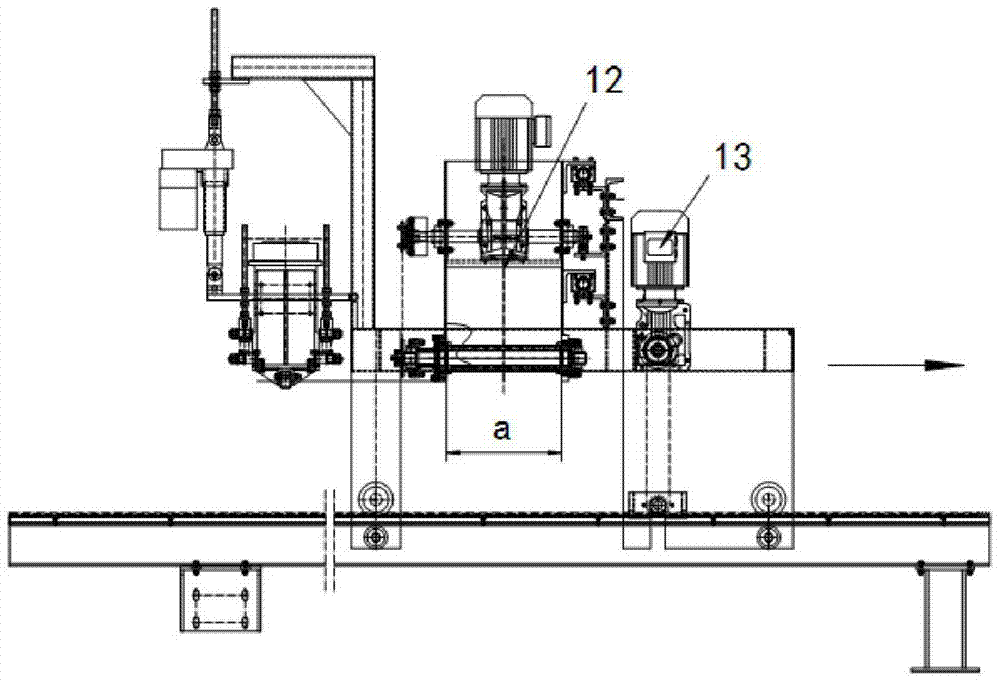

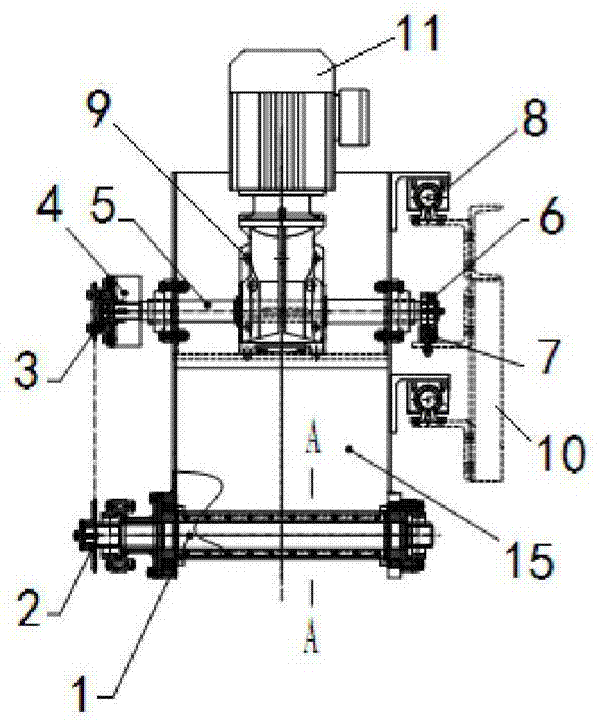

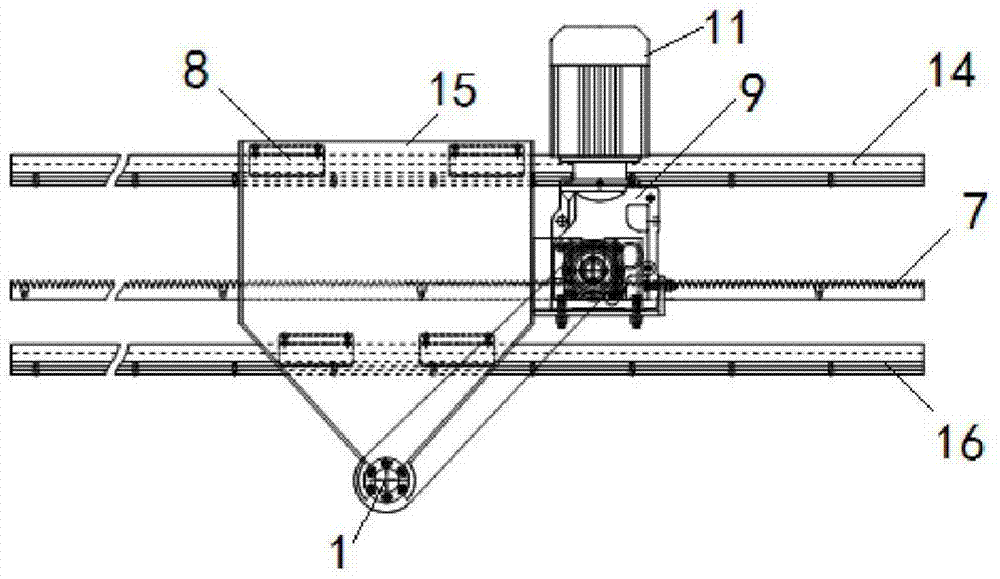

[0025] Embodiment 1: as figure 1 , figure 2 , image 3 and Figure 4 As shown, a continuous automatic cement distributing device, the motor 11 is fixed on the box body 9, and the box body 9 is respectively connected to the first slide rail 14 and the second slide rail 16 on the frame 15 through four sliders 8, and the rack 7. The first slide rail 14 and the second slide rail 16 are respectively fixed on the bracket 10, the motor 11 is connected with the drive shaft 5; the two ends of the drive shaft 5 are respectively connected with the travel gear 6 and the electromagnetic clutch 4; The strip 7 is engaged, the electromagnetic clutch 4 is connected with the driving sprocket 3; the driving sprocket 3 and the driven sprocket 2 are connected through a chain; the cloth wheel 1 is connected with the driven sprocket 2; the cloth wheel 1 is connected with the flange, the bearing and the box 9 Make the connection.

[0026] The support 10 is connected with a moving motor 13 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com