Catalyst for preparing phenylethane from dilute ethylene and benzene alkylation and method for preparing same

A benzene alkylation and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of high alkylation reaction temperature, high energy consumption, and high xylene impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The silicon-aluminum molar ratio is 25, and the ZSM-5 molecular sieve that crystal grain size is 0.7 micron is mixed with the ratio that alumina is 7: 3 with the mass ratio, adds the turmeric powder that accounts for 3.0% of dry basis weight and accounts for dry basis weight After 4% nitric acid, kneading, extruding, and roasting;

[0024] Use ammonium nitrate aqueous solution as an exchange agent to carry out ion exchange on the above-mentioned shaped samples, and turn them into hydrogen-type molecular sieves after roasting;

[0025] The above sample was treated with water vapor at 550°C for 2 hours; then treated with 0.1mol / L nitric acid solution at 70°C for 3 hours, the weight ratio of nitric acid solution to catalyst was 5, and the catalyst was dried and heated at 520°C Calcined for 2 hours to obtain catalyst A.

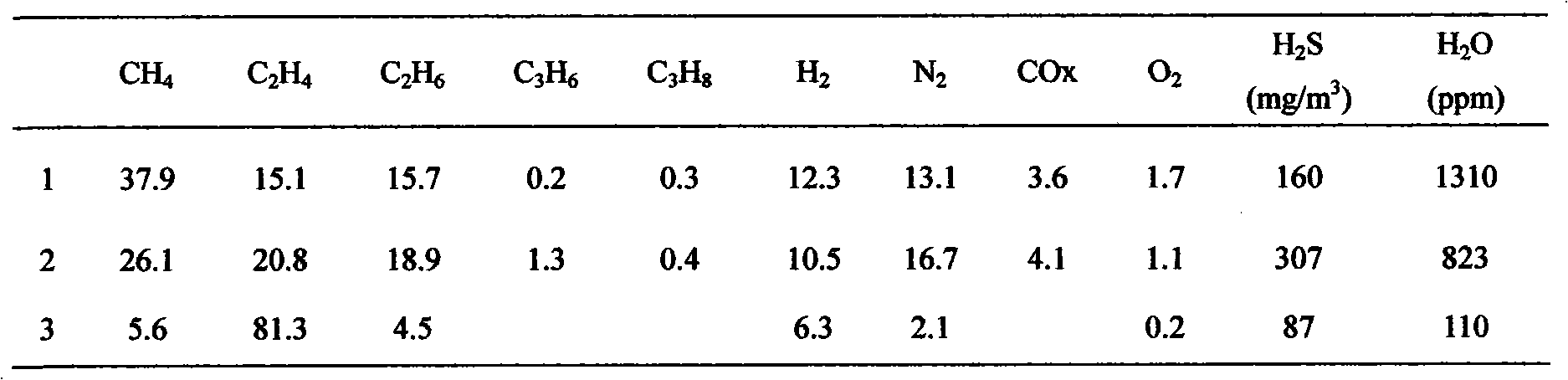

[0026] Under the condition that the reaction temperature is 330°C and the pressure is 0.7MPa, using the No. 1 dry gas raw material in Table 1, the ethyle...

Embodiment 2

[0028] Catalyst preparation process is the same as embodiment 1, and difference is that after acid treatment, catalyst is impregnated with La 2 o 3 A calculated amount of 1.0% lanthanum nitrate solution was dried and calcined to obtain catalyst B.

[0029] Under the condition that the reaction temperature is 330°C and the pressure is 0.7MPa, the No. 2 dry gas raw material in Table 1 is used, the ethylene content is 20.8% (volume), and the ethylene space velocity is 0.4h -1 , under the condition that the molecular ratio of benzene to ethylene is 5, the ethylene conversion rate is 99.7%, the ethylation selectivity is 99.2%, the xylene impurity content is 830ppm, and the activity of the catalyst decreases by 0.21% during 100 hours of operation.

Embodiment 3

[0034] The silicon-aluminum molar ratio is 196, and the ZSM-5 molecular sieve that grain size is 0.2 micron is mixed with silicon dioxide in the ratio of 9: 1 with the mass ratio, adds and accounts for 2.0% of dry basis weight's turmeric powder and accounts for dry basis 11% by weight of nitric acid, kneading and extruding to shape, use ammonium chloride aqueous solution as the exchanger, carry out ion exchange on the above-mentioned shaped samples, after roasting, turn them into hydrogen-type molecular sieves, and treat them with ammonia water vapor under the condition of 450°C 2 hours, wherein the concentration of ammonia water is 0.2mol / L; then treat with 0.3mol / L nitric acid solution at 50°C for 3 hours, wherein the weight ratio of nitric acid solution to catalyst is 3; the catalyst is dried and calcined at 520°C for 2 hours , Catalyst D was prepared.

[0035] Under the condition that the reaction temperature is 360°C and the pressure is 1.8MPa, the No. 2 dry gas raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com