Method for recycling ammonia from low concentration ammonium chloride wastewater

A low-concentration technology of ammonium chloride, which is applied in the field of ammonia recovery, can solve the problems of low ammonia and hydrochloric acid concentrations, unusability, inability to form industrialized production, and large heat energy consumption, and achieve low cost, easy availability, and high ammonia concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

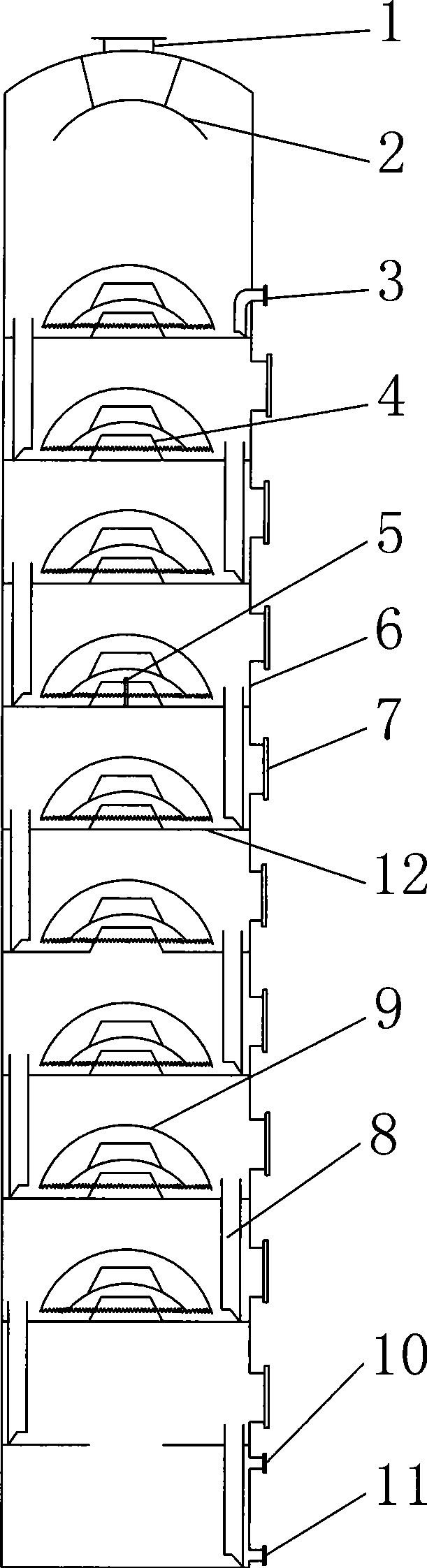

Image

Examples

Embodiment 1

[0038]Alkaline substance selects sodium hydroxide solution for use, the weight ratio of sodium hydroxide in the sodium hydroxide solution and ammonium chloride in the low-concentration ammonium chloride waste water is 1: 1.3-1.6, carries out the mixing reaction of above-mentioned step (1) successively process, the ammonia separation and concentration process in step (2), the cooling recovery process in step (3) and the discharge waste liquid treatment process in step (4), finally obtaining ammonia water.

Embodiment 2

[0040] Alkaline substance selects electric gypsum for use, and the weight ratio of electric gypsum and ammonium chloride in the low-concentration ammonium chloride wastewater is 1: 1-1.5, carries out the mixing reaction technique of above-mentioned step (1), will step (1) After the obtained mixed slurry is settled to remove particulate matter impurities, the ammonia separation and concentration process of step (2), the cooling recovery process of step (3) and the discharge waste liquid treatment process of step (4) are sequentially entered to finally obtain ammonia water.

Embodiment 3

[0042] Alkaline substance selects quicklime for use, and the weight ratio of quicklime and ammonium chloride in the low-concentration ammonium chloride waste water is 1: 0.5-1, carries out the mixed reaction technique of above-mentioned step (1), the obtained in step (1) After the mixed slurry is settled to remove particulate matter impurities, it then enters step (2) ammonia separation and concentration process, step (3) cooling recovery process and step (4) discharge waste liquid treatment process, and finally ammonia water is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com