Method for preparing high-concentration ammonia by separating and purifying low-concentration aqueous ammonia

A low-concentration, high-concentration ammonia technology, applied in the preparation/separation of ammonia, can solve the problem of producing a large amount of dilute ammonia water, and achieve the effects of not causing pipeline blockage, low equipment investment cost, and high separation and purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

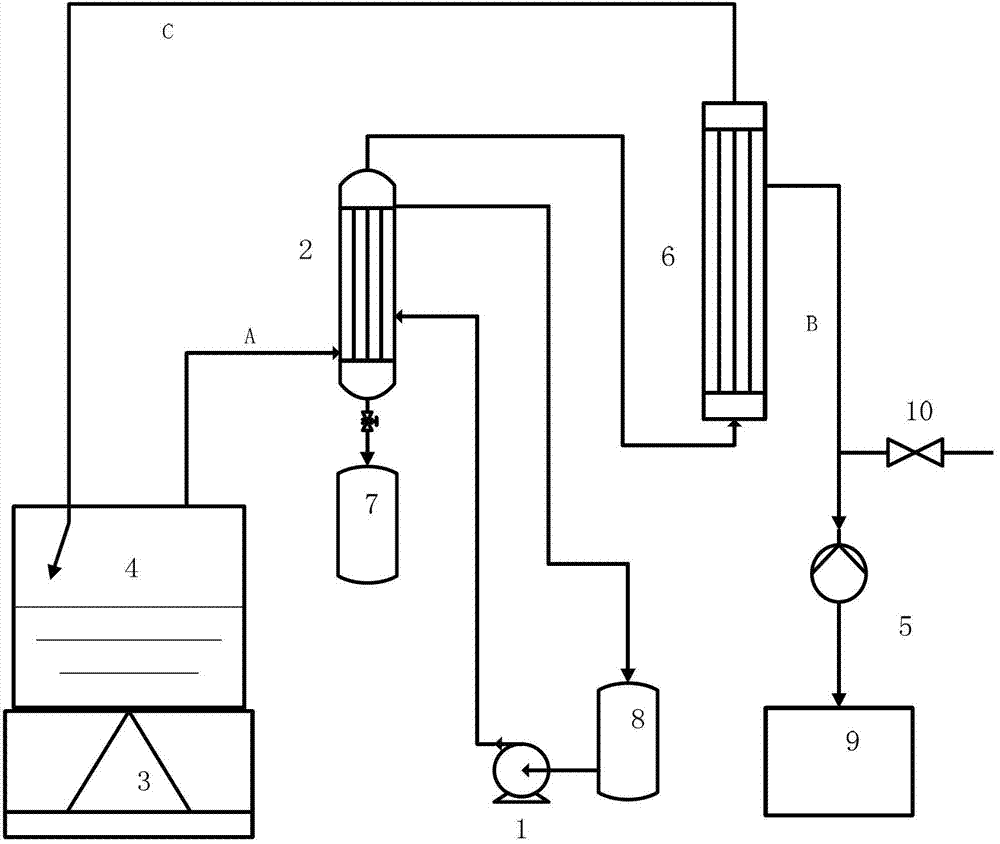

Image

Examples

Embodiment 1

[0046] Operate according to process steps 1) to 8), and the control parameters are as follows: Step 2) The preset initial temperature of the heating tank is 46°C, Step 4) The vacuum degree outside the membrane still is maintained at 0.03-0.06MPa, and Step 5) The heating rate is set to 2 °C / 10min, step 8) The preset termination temperature of the heater is 88 °C. When the initial concentration is 20.07%, the water content of ammonia gas after separation is 1.30%, see Table 1.

[0047] Table 1 Changes in moisture content of ammonia gas under programmed temperature rise mode

[0048] Example

Embodiment 2

[0050] Operate according to process steps 1) to 8), and the control parameters are as follows: step 2) the preset initial temperature of the heater is 46°C, step 4) maintain the vacuum degree outside the membrane still at 0.03 ~ 0.06MPa, step 5) set the heating rate to 6 °C / 10min, step 8) The preset termination temperature of the heater is 88 °C. When the initial concentration is 20.03%, the water content of ammonia gas after separation is 1.43%, see Table 1.

Embodiment 3

[0052]Operate according to process steps 1) to 8), and the control parameters are as follows: step 2) the preset initial temperature of the heater is 46°C, step 4) maintain the vacuum degree outside the membrane still at 0.03 ~ 0.06MPa, step 5) set the heating rate to 6 °C / 10min, step 8) The preset termination temperature of the heater is 88 °C. When the initial concentration is 19.87%, the water content of ammonia gas after separation is 1.15%, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com