Solid waste heat insulation device for outer surface of surrounding rock of roadway and a construction process thereof

A heat insulation device and outer surface technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of large heat exchange volume, uneconomical cost, and waste of energy in roadways, and achieve good heat insulation performance and support capacity. Reduce the occupation of cultivated land and achieve the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

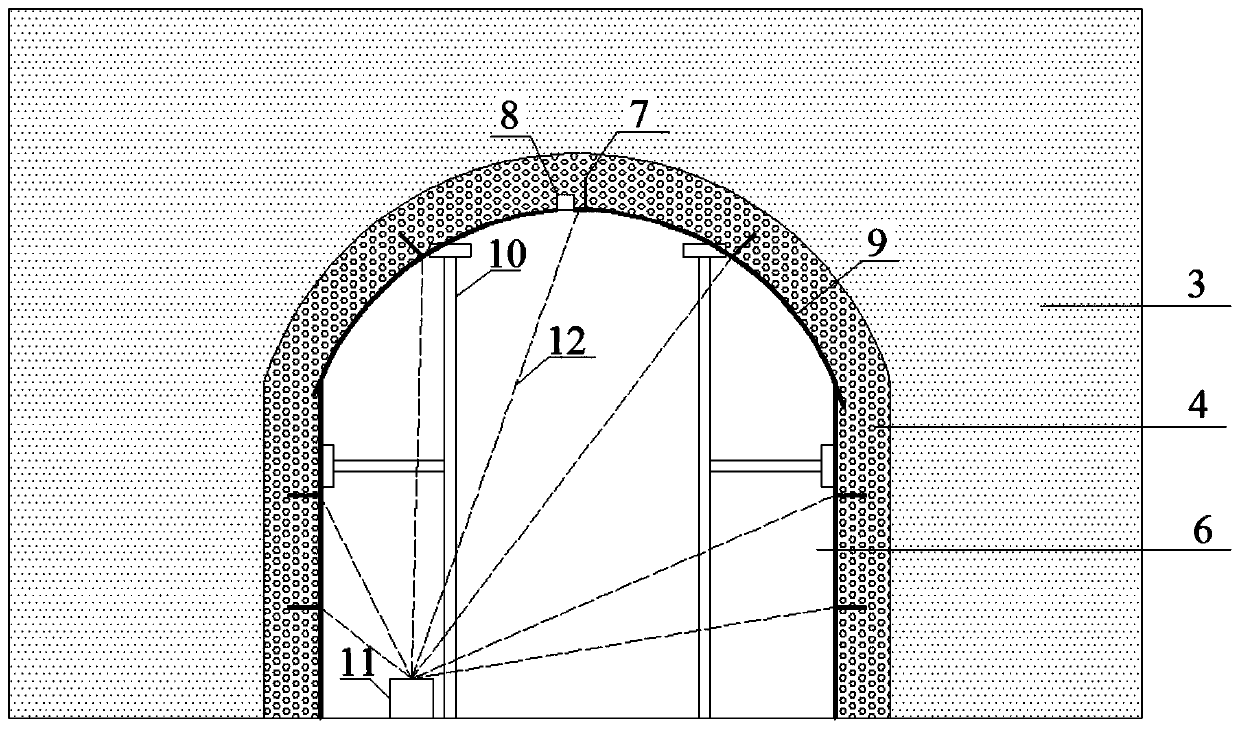

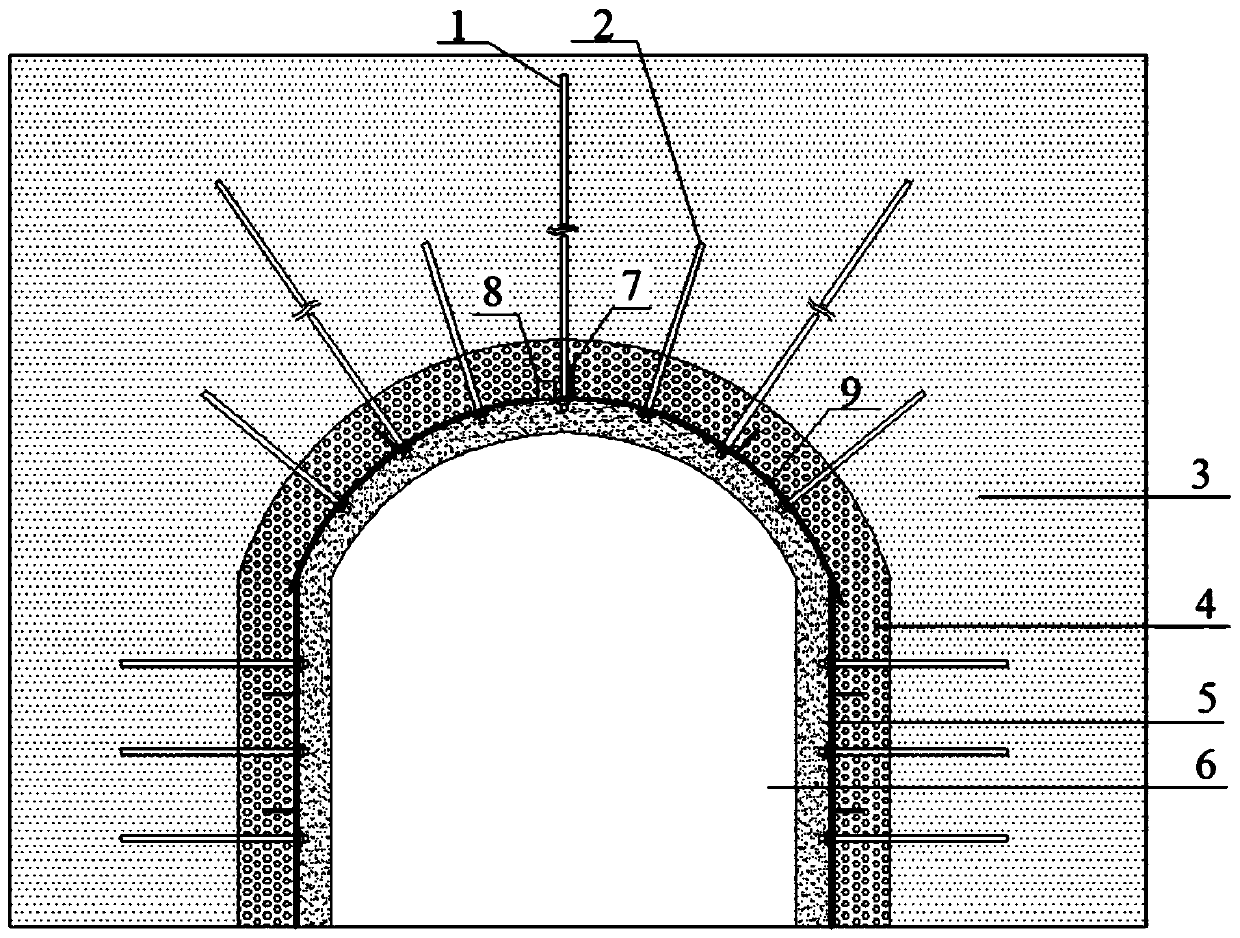

[0029] Figure 1-2 A specific embodiment of the present invention is shown: a solid waste heat insulation device for the outer surface of roadway surrounding rock includes: anchor cable 1, anchor rod 2, surrounding rock 3, solid waste heat insulation material 4, concrete layer 5, roadway 6 , silicon carbide heating rod 7, material injection port 8, corundum plate 9, temporary support device 10, variable pressure heating device 11, cable 12, the roadway 6 is arranged inside the surrounding rock 3, and the corundum plate 9 passes through the anchor cable 1, The bolt 2 is set on the outer surface of the surrounding rock 3, the solid waste heat insulation material 4 is set in the middle of the corundum plate 9 and the surrounding rock 3, the temporary support device 10 is set against the corundum plate 9, and the injection port 8 is set on the surrounding rock 3, the silicon carbide heating rod 7 is set on the surrounding rock 3, the variable pressure heating device 11 is independ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com