Method and system for producing glass fiber products by using liquid deslagging boiler

A technology of liquid slag removal and glass fiber, which is applied in glass manufacturing equipment, glass furnace equipment, felting equipment, etc., can solve the problems of high temperature flue gas affecting environmental protection, restrictions on rock wool manufacturing industry, factory shutdown, etc., and achieve improvement Energy utilization efficiency, increasing economic benefits and social benefits, and reducing solid waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

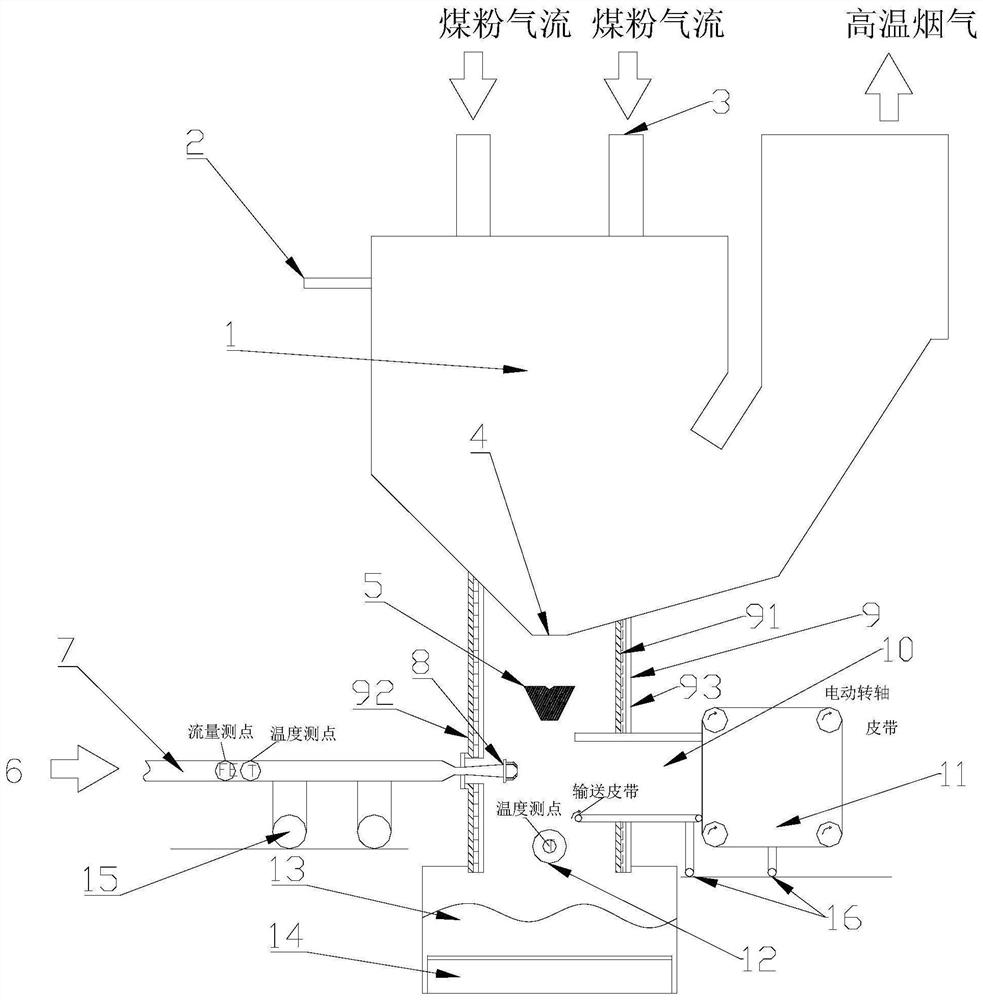

[0063] see figure 1 As shown, this embodiment provides a system for producing glass fiber products using a liquid slagging boiler. The system includes slag system, cotton system, waste gas and slag treatment system and emergency equipment exit system. The recycling of solid waste and the production of glass fiber products are realized by using four branch systems.

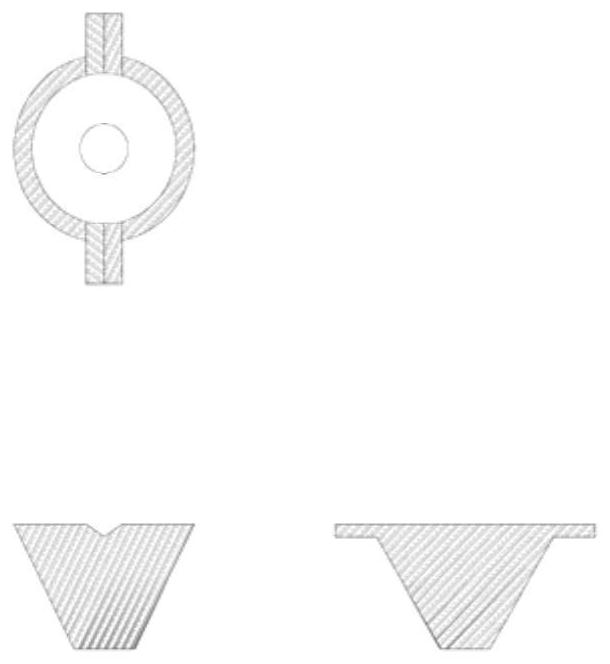

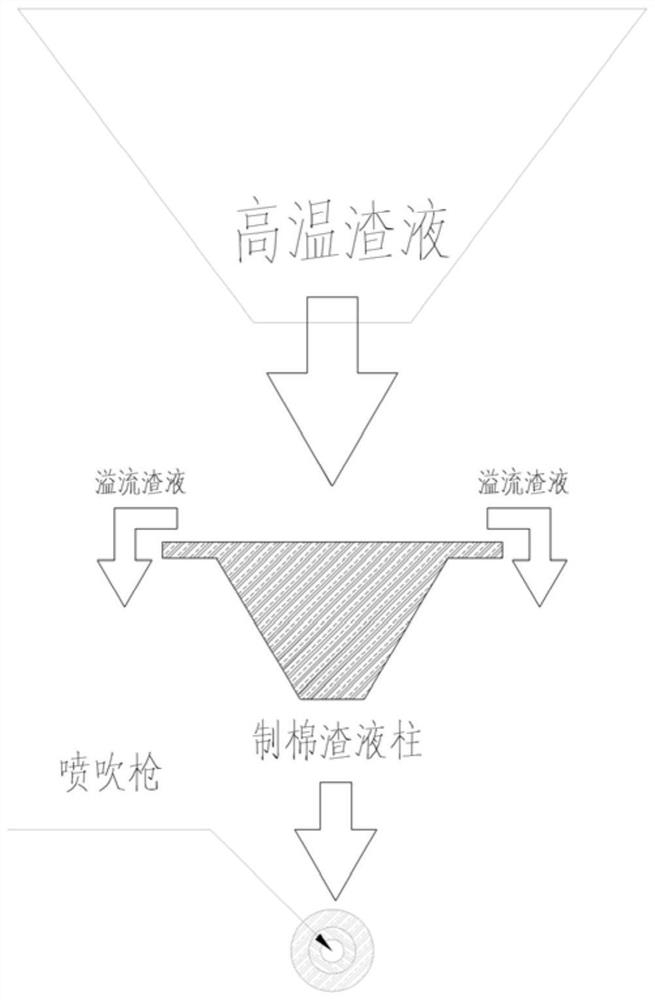

[0064] Specifically, the slag system includes a liquid slag discharge boiler 1, the furnace wall of the liquid slag discharge boiler 1 is provided with an in-furnace conditioner nozzle 2, and the bottom of the liquid slag discharge boiler 1 is provided with a slag outlet 4, and the cotton making system includes The overflow funnel 5, the slag hopper 9, the blowing gun 8, the blowing pipe 7, the cotton collection chamber 10 and the felt rolling machine 11, the slag outlet 4 is located above the overflow funnel 5, and the overflow funnel 5 is located in the slag hopper 9, The spray gun 8 has a nozzle end extending ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com