Environment-friendly process for quizalofop-p-ethyl production

A kind of quizalofop-p-ethyl, environment-friendly technology, applied in the field of environment-friendly process for producing quizalofop-p-ethyl, can solve the problems of complicated steps, low etherified product content, high alkali concentration, etc., to reduce the generation of impurities and improve the utilization efficiency, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

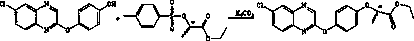

Image

Examples

Embodiment 1

[0033] Weigh 11.6g (0.105mol) of hydroquinone and 4.3g (0.105mol) of sodium hydroxide under nitrogen protection, add 60g of toluene and raise the temperature to 85°C for 0.5h, cool down and transfer to a constant pressure dropping funnel for later use. Add 20.2g (0.1mol) 2,6-dichloroquinoxaline and 220g toluene under the protection of nitrogen, raise the temperature to 100°C, add the prepared sodium salt of hydroquinone dropwise, finish dropping for 1 hour, and keep warm for 6 hours after dropping , sampling follow-up, the content of 2,6-dichloroquinoxaline is less than 0.5%, and after passing the pass, cool down to room temperature, filter and dry the filter cake, wash it with hot water until neutral to obtain 4-(6-chloro-2-quinoxaline oxygen Base) phenol 25.3g, content 96.2%, yield 89.3%.

[0034] Add 0.1mol of 4-(6-chloro-2quinoxalineoxy)phenol synthesized under nitrogen protection, 21.6g (0.156mol) of potassium carbonate, add 710g of non-polar solvent, heat up to anhydrous...

Embodiment 2

[0038]Weigh 14.3g (0.13mol) of hydroquinone and 4.7g (0.115mol) of sodium hydroxide under the protection of nitrogen, add 72g of toluene and raise the temperature to 85°C for 0.5h, cool down and transfer to a constant pressure dropping funnel for later use. Add 20.2g (0.1mol) 2,6-dichloroquinoxaline and 220g toluene under the protection of nitrogen, raise the temperature to 100°C, add the prepared sodium salt of hydroquinone dropwise, finish dropping for 1 hour, and keep warm for 6 hours after dropping , sampling follow-up, the content of 2,6-dichloroquinoxaline is less than 0.5%, and after passing the pass, cool down to room temperature, filter and dry the filter cake, wash it with hot water until neutral to obtain 4-(6-chloro-2-quinoxaline oxygen Base) phenol 25.7g, content 98.5%, yield 92.8%.

[0039] Add 0.1mol of 4-(6-chloro-2-quinoxalineoxy)phenol synthesized under nitrogen protection, 21.6g of potassium carbonate, add 730g of non-polar solvent, and add p-toluenesulfonic...

Embodiment 3

[0043] Weigh 12.7g (0.115mol) of hydroquinone and 4.3g (0.105mol) of sodium hydroxide under nitrogen protection, add 75g of toluene and raise the temperature to 85°C for 0.5h, cool down and transfer to a constant pressure dropping funnel for later use. Add 20.2g (0.1mol) 2,6-dichloroquinoxaline and 250g toluene under nitrogen protection, heat up to 100°C, add the prepared sodium salt of hydroquinone dropwise, finish dropping for 1 hour, and keep warm for 6 hours after dropping , sampling follow-up, the content of 2,6-dichloroquinoxaline is less than 0.5%, and after passing the pass, cool down to room temperature, filter and dry the filter cake, wash it with hot water until neutral to obtain 4-(6-chloro-2-quinoxaline oxygen Base) phenol 25.8g, content 98.8%, yield 93.5%.

[0044] Add 0.1mol of the 4-(6-chloro-2-quinoxalineoxy)phenol synthesized above under nitrogen protection, 21.6g of potassium carbonate, add 700g of non-polar solvent, and add p-toluenesulfonic acid lactic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com