Composition for preparing ultralight ceramsite, ceramsite and preparation method thereof

A composite, ultra-light ceramic technology, applied in the application, ceramic products, clay products and other directions, can solve the problems of jarosite slag pollution, poor comprehensive utilization rate, environmental impact, etc., to reduce solid waste discharge, low water absorption, The effect of effective preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] There is no particular limitation on the preparation method of the ceramsite, which can be prepared by methods known in the art, and the discontinuous firing process can be used in the process, or the rotary kiln can be used for continuous firing.

[0042] An example is prepared as follows:

[0043] Make each component into a powder, mix evenly, add an appropriate amount of water to the mixed powder to make a ball, and make a ball blank;

[0044] The obtained spheroids are dried, preheated, fired at high temperature, and ceramsite is obtained after cooling.

[0045] The ceramsite prepared by the method has the excellent properties of the above-mentioned product examples, and at the same time, the process is simple, and is suitable for popularization and use.

[0046] The method of making each component into a powder is exemplified as follows: after crushing each component, drying, ball milling, and sieving. The particle size of the sieved powder is not coarser than 10...

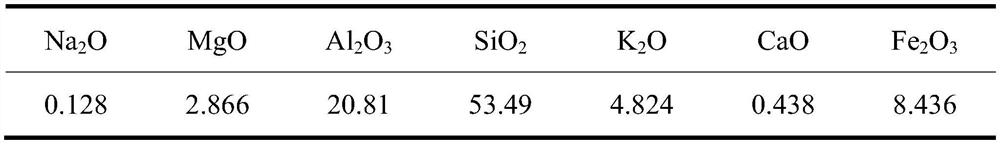

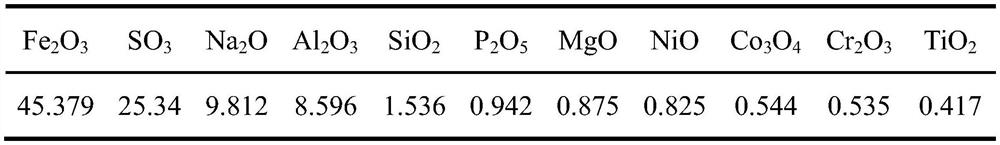

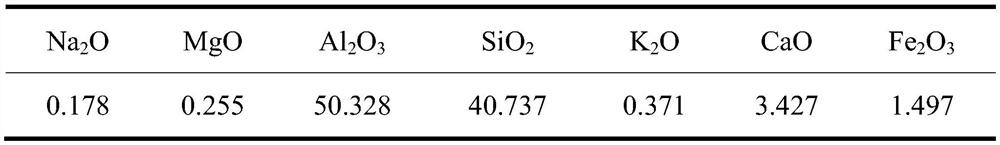

Embodiment 1

[0067] The composition for preparing ultra-light ceramsite comprises shale, alum slag and aluminum-containing silicon carbide waste, and the mass ratio is 185:15:2.

[0068] The preparation steps of ceramsite are as follows:

[0069] (1) Drying and grinding: Dry the crushed shale, alum slag and aluminum-containing silicon carbide waste in an oven at 105°C to constant weight, put the dried materials into a ball mill and grind them to fineness, and pass through 100 mesh Sieve to get powder.

[0070] (2) Weighing: Weigh the powder of shale, jarosite slag and aluminum-containing silicon carbide waste according to the mass ratio of 185:15:2.

[0071] (3) Mixing: Put the weighed powder into a ball mill and mix for 5 minutes.

[0072] (4) Forming: Add appropriate amount of water to the mixed material and fully squeeze it into a ball, put the ball into a 10mm strip forming device to extrude into strips, and use a 10mm pressure ball plate to press the extruded strips into strips Bla...

Embodiment 2

[0078] The composition for preparing ultra-light ceramsite comprises shale, alum slag and aluminum-containing silicon carbide waste in a mass ratio of 90:10:1.

[0079] The preparation steps of ceramsite are as follows:

[0080] (1) Drying and grinding: Dry the crushed shale, alum slag and aluminum-containing silicon carbide waste in an oven at 105°C to constant weight, put the dried materials into a ball mill and grind them to fineness, and pass through 100 mesh Sieve to get powder.

[0081] (2) Weighing: Weigh the powder of shale, jarosite slag and aluminum-containing silicon carbide waste according to the mass ratio of 90:10:1.

[0082] (3) Mixing: Put the weighed powder into a ball mill and mix for 5 minutes.

[0083] (4) Forming: Add appropriate amount of water to the mixed material and fully squeeze it into a ball, put the ball into a 10mm strip forming device to extrude into strips, and use a 10mm pressure ball plate to press the extruded strips into strips Blank.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com