Active cooling and combustion decoupling system of scramjet engine

A scramjet and active cooling technology, which is applied to the cooling of engines, ramjet engines, engine components, etc., can solve the problems of reducing cooling fuel flow and unsuitable supercritical carbon dioxide system layout, etc., to reduce cooling fuel flow, The effect of reducing heat and ensuring safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

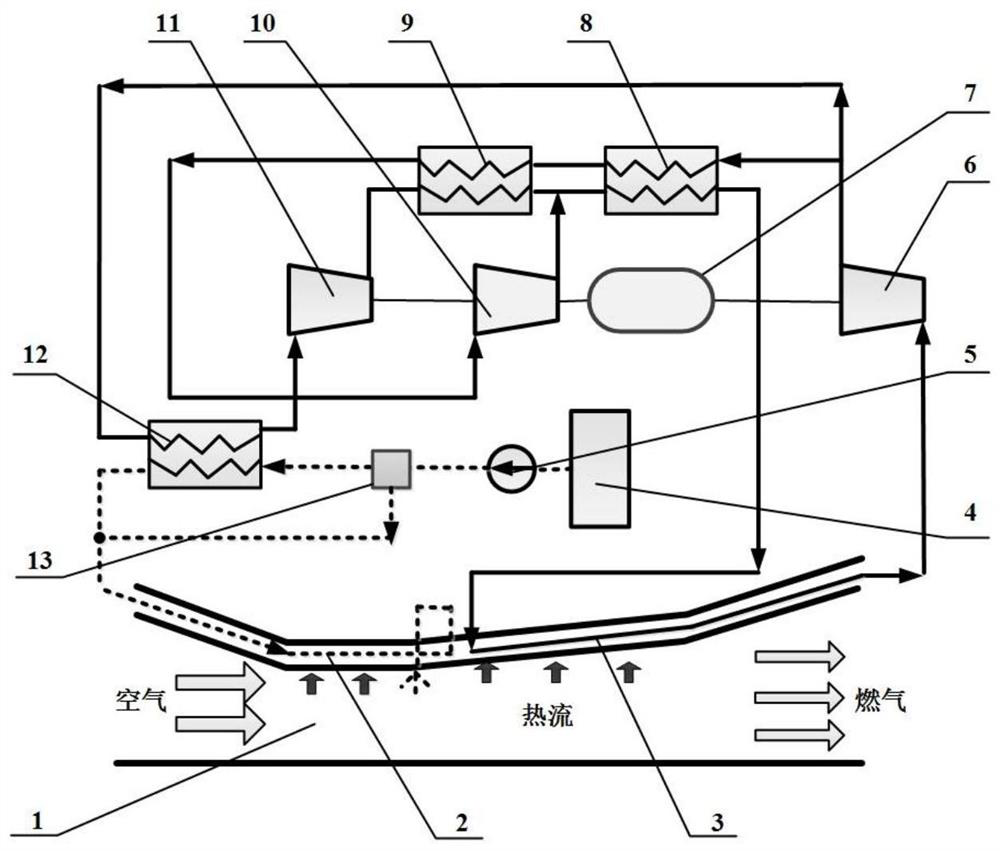

[0028] refer to figure 1 The scramjet active cooling and combustion decoupling system provided in this embodiment includes a scramjet 1, a first wall cooling channel 2, a second wall cooling channel 3, a fuel tank 4, a fuel pump 5, and a turbine 6 , generator 7, high temperature regenerator 8, low temperature regenerator 9, second compressor 10, first compressor 11, fuel heat exchanger 12 and diverter valve 13.

[0029] In order to ensure that the fuel has a sufficiently high temperature rise and reduce the flow rate of the cooling fuel to the greatest extent, this embodiment proposes two measures: one is to change the split flow position of the traditional recompression supercritical carbon dioxide cycle, and to split the flow at the outlet of the turbine to This increases the inlet temperature of the thermal fluid in the fuel heat exchanger. The second is to increase the temperature of carbon dioxide at the inlet of the compressor so that it is higher than the critical temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com