Device and method for controlling inlet temperature of three-way catalytic converter according to OBD monitoring efficiency

A three-way catalytic converter and control relay technology, applied in the direction of muffler device, exhaust device, electronic control of exhaust treatment device, etc., can solve the problem of low conversion efficiency of three-way catalytic converter, limitation of three-way catalytic converter layout, catalytic Conversion efficiency decline and other problems, to achieve the effect of shortening the light-off time, reducing limitations, and reducing the use of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

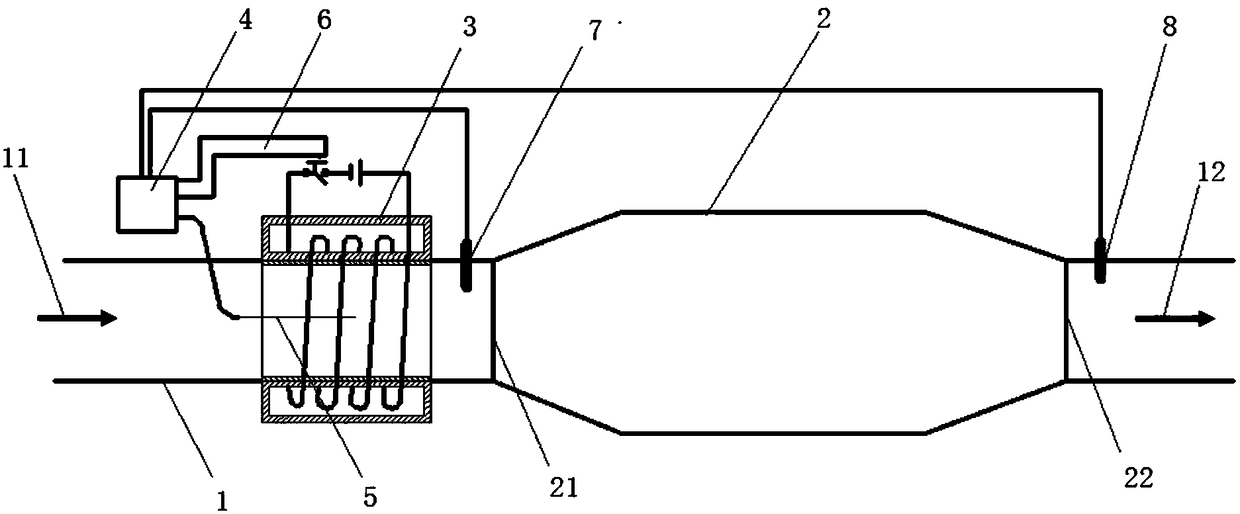

[0026] Such as figure 1 As shown, the device for controlling the inlet temperature of the three-way catalytic converter according to the OBD monitoring efficiency of a preferred embodiment of the present invention includes: an exhaust pipe 1, a three-way catalytic converter 2, an electric heating device 3 and an engine electronic control system 4, wherein the exhaust pipe Air duct 1 includes an engine exhaust gas inlet port 11 . The three-way catalytic converter inlet port 21 is connected to the engine exhaust gas inlet port 1 . The electric heating device 3 is arranged outside the exhaust pipe 1 and arranged close to the inlet port 21 of the three-way catalytic converter, and is used for heating the exhaust gas in front of the inlet port of the three-way catalytic converter. The engine electronic control system 2 includes an electronic control unit (ECU), an OBD system, an exhaust temperature sensor 5, a concentration sensor and a control relay 6, wherein the concentration s...

Embodiment 2

[0029] According to another preferred embodiment of the present invention, the device for controlling the inlet temperature of the three-way catalytic converter according to the OBD monitoring efficiency includes: an exhaust pipe, a three-way catalytic converter, an electric heating device, and an electronic engine control system, wherein the exhaust pipe includes engine exhaust entry port. The inlet port of the three-way catalytic converter is connected to the inlet port of the exhaust gas of the engine. The electric heating device is arranged outside the exhaust pipe and arranged close to the inlet end of the three-way catalytic converter, and is used for heating the exhaust gas before the inlet end of the three-way catalytic converter. The engine electronic control system includes electronic control unit (ECU), OBD system, exhaust temperature sensor, concentration sensor and control relay. Control the on and off of the control relay to control the working state of the elec...

Embodiment 3

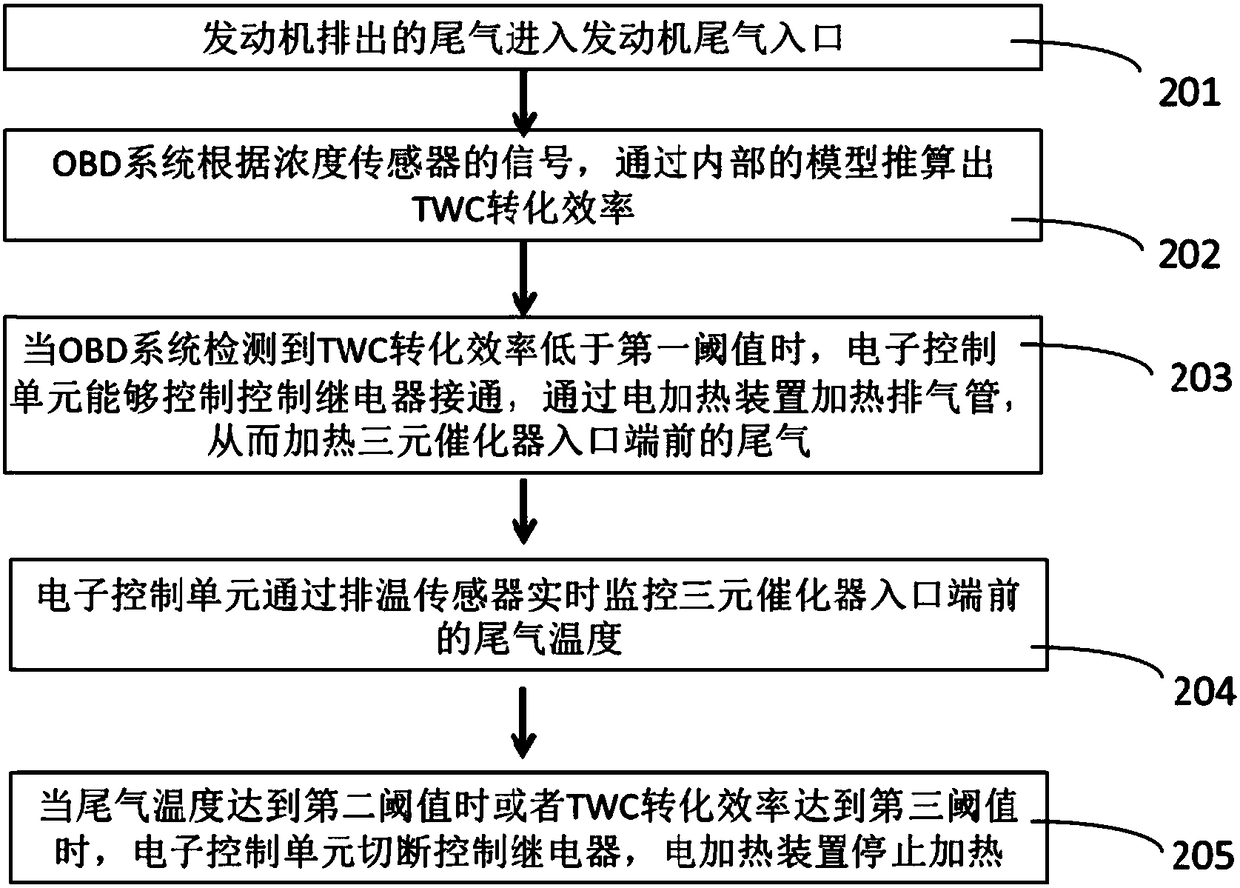

[0032] The present invention also provides a method for controlling the inlet temperature of the three-way catalytic converter according to the OBD monitoring efficiency, comprising the following steps: Step 101: the exhaust gas discharged from the engine enters the engine exhaust inlet; Step 102: the OBD system passes the internal The conversion efficiency of the three-way catalytic converter is calculated by the model; Step 103: When the OBD system detects that the conversion efficiency of the three-way catalytic converter is lower than the first threshold, the electronic control unit can control the control relay to be turned on, and the exhaust pipe is heated by the electric heating device , so as to heat the exhaust gas before the inlet end of the three-way catalytic converter; step 104: the electronic control unit monitors the exhaust gas temperature before the inlet end of the three-way catalytic converter in real time through the exhaust temperature sensor; and step 105:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com