High temperature gas cooled reactor nuclear power unit secondary circuit starting and stopping system and method

A technology for high-temperature gas-cooled reactors and nuclear power units, which is applied in the field of nuclear power, can solve the problems of loss of heating by deaerators, reduce steam turbine efficiency, and poor heating effect, and achieve the effects of increasing feed water temperature, improving safety, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

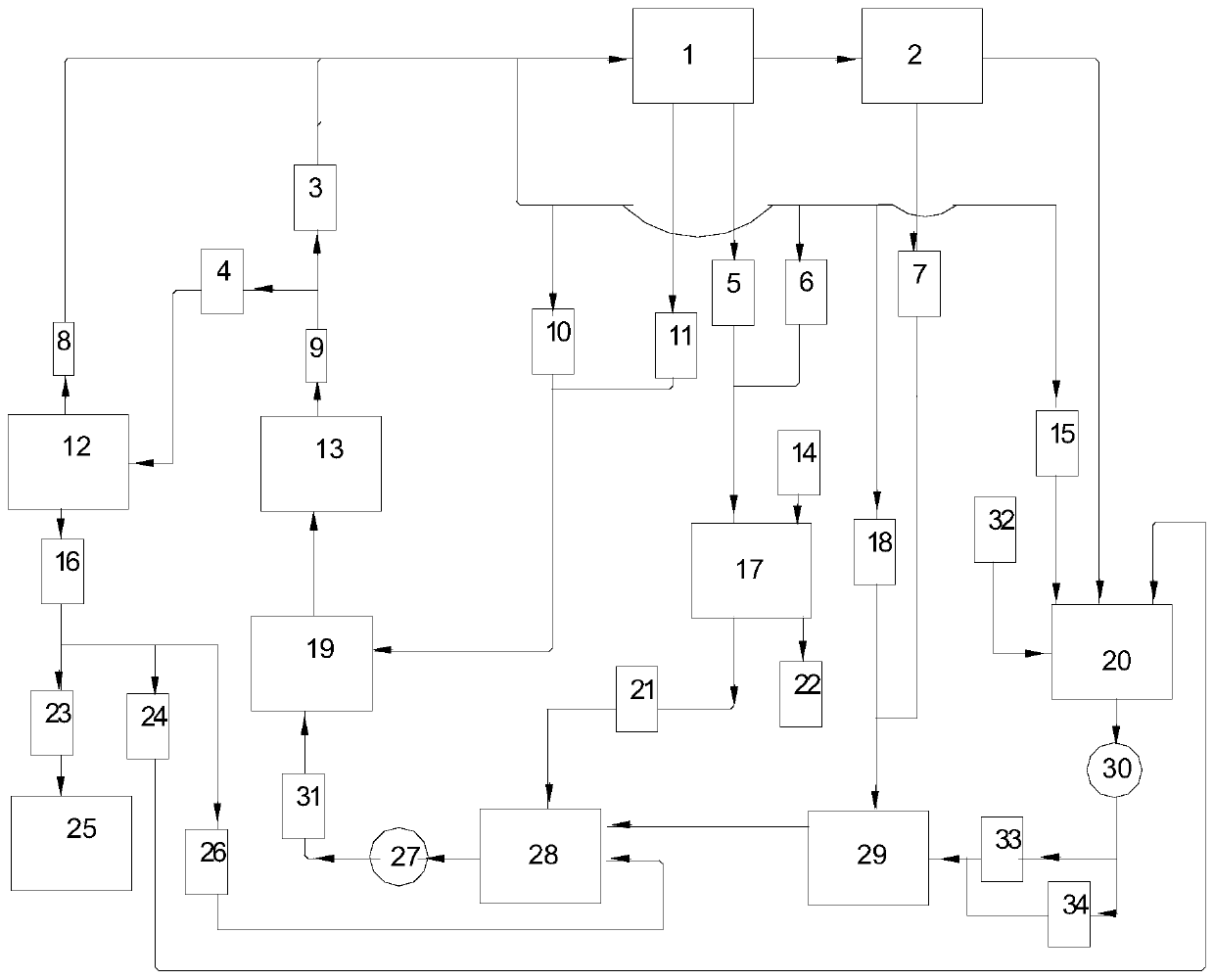

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0064] Such as figure 1 As shown, a system for starting and stopping the secondary circuit of a high-temperature gas-cooled reactor nuclear power unit provided by the present invention includes an evaporator 13, a steam-water separator 12, a unit drainage tank 25, a deaerator 28, a condenser 20, and a first valve Group 9, second valve group 3, third valve group 4, fourth valve group 8, fifth valve group 16, sixth valve group 23, seventh valve group 24 and eighth valve group 26.

[0065] Wherein, the outlet of the evaporator 13 is connected to the inlet of the first valve group 9, the outlet of the first valve group 9 is divided into two strands, the first strand is connected to the inlet of the second valve set 3, and the second strand is connected to the third valve The inlet of group 4, the outlet of the third valve group 4 is connected to the inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com