System with extraction condensing unit changed into back pressure unit on basis of spraying heat pump and operation method of system

A technology of back pressure unit and condensing unit, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problem of inability to meet the electricity demand of self-contained power stations, the inability to meet the steam requirements of thermal users, and the economic discount of the whole plant and other problems, to achieve the effect of improving the efficiency of cascade utilization, reducing the investment cost of equipment and pipelines, and reducing the cost of transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

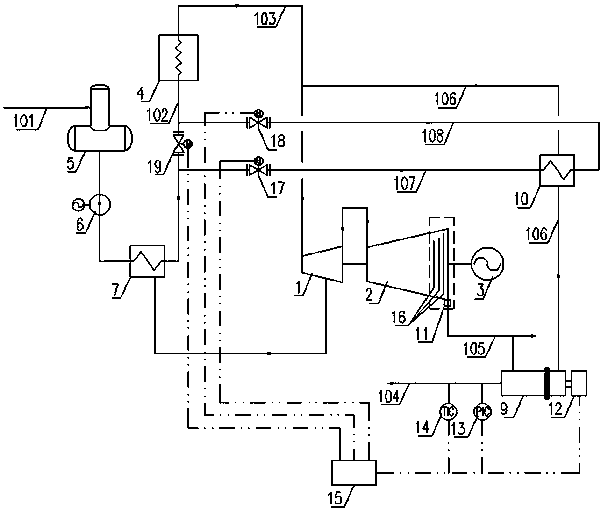

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] see figure 2 , the embodiment of the present invention includes a high-pressure cylinder 1, a low-pressure cylinder 2, a condensing unit power station 3, a boiler 4, a deaerator 5, a feed water pump 6, a high-pressure heater 7, a jet heat pump 9, a water heater 10, and a cooling device 11 , Steam regulating valve 12 inside the jet heat pump, pressure transmitter 13, temperature transmitter 14, control system 15, No. 1 valve 19, No. 2 valve 17, No. 3 valve 18, water supply pipeline 101 for the whole plant, boiler water supply pipeline 102. Main steam inlet pipeline 103, high-pressure heating steam pipeline 104, low-pressure heating steam pipeline 105, high-pressure driving steam pipeline 106, water heater inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com