High-purity ammonia on-site manufacturing method and manufacturing device

An on-site manufacturing, high-purity technology, applied in the field of high-purity ammonia on-site manufacturing methods and manufacturing devices, to achieve the effects of simple process, reduced investment costs, and reduced logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

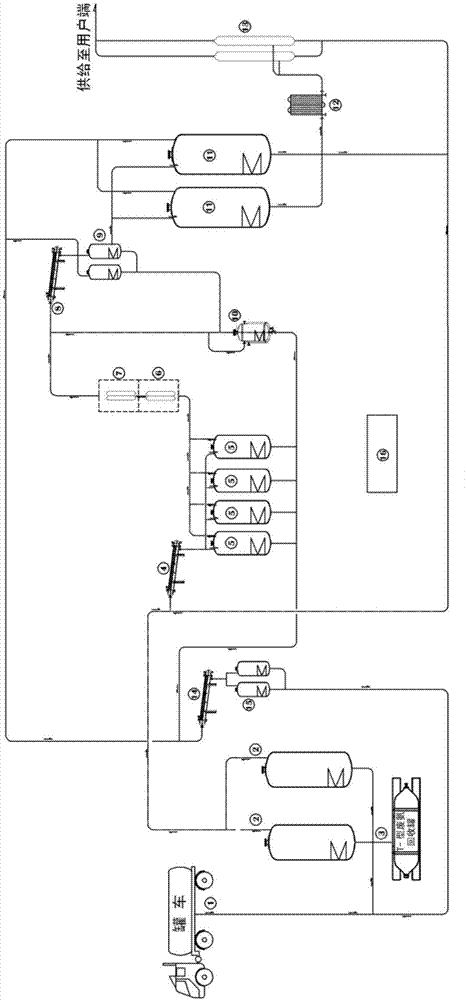

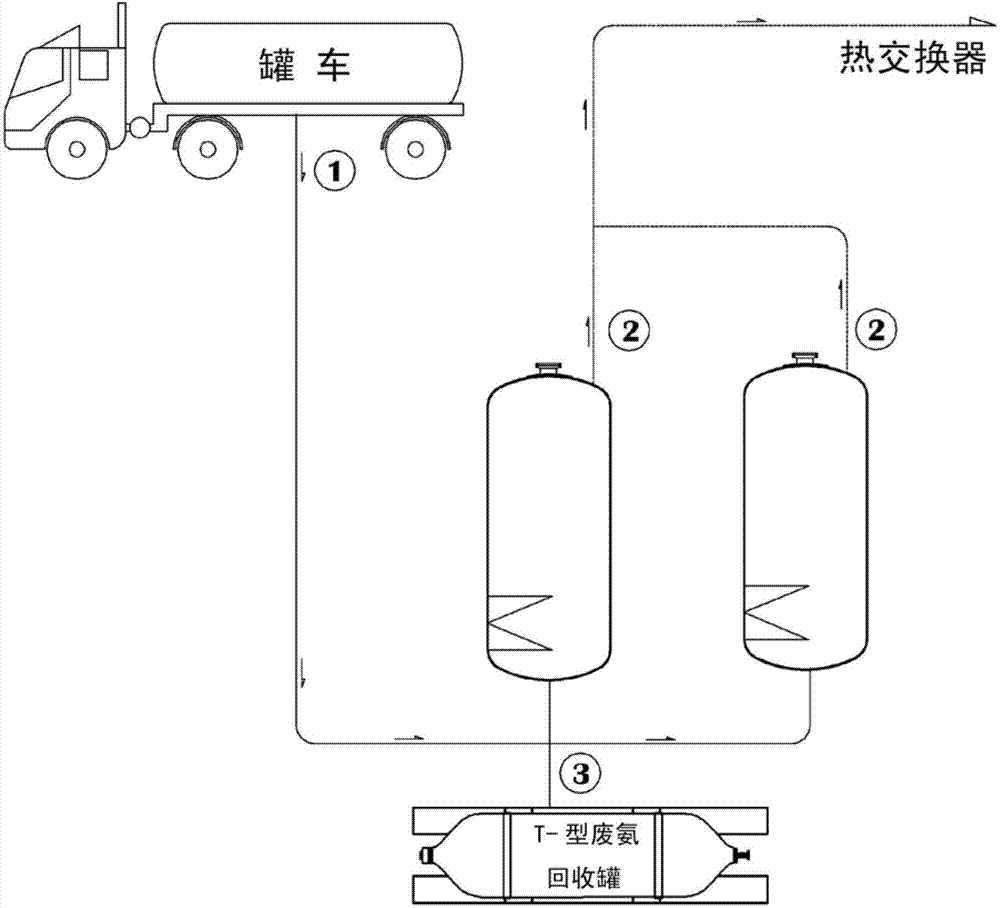

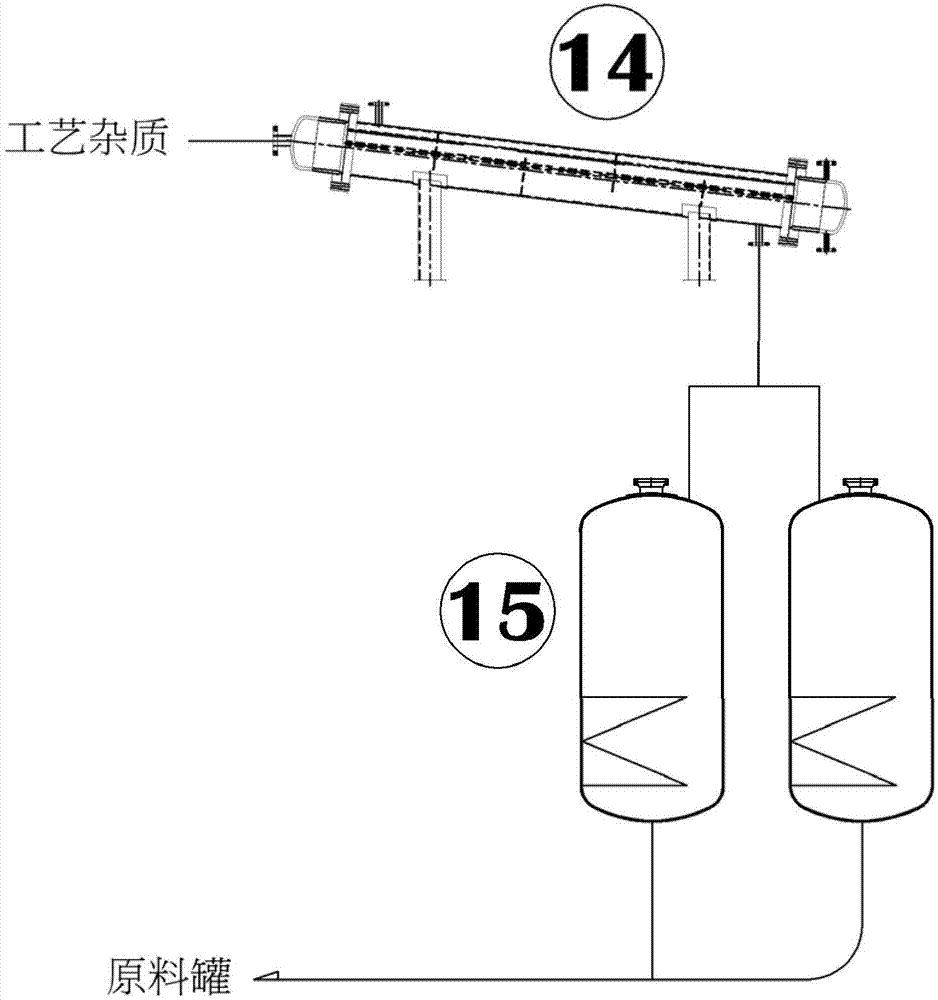

[0030] figure 1 It is a schematic diagram of the overall structure of the high-purity ammonia on-site manufacturing device according to a preferred embodiment of the present invention; Figure 2 to Figure 6 Enlarged view of each part.

[0031] The high-purity ammonia on-site manufacturing device according to a preferred embodiment of the present invention is composed of a tank car 1 for supplying raw materials, a raw material storage tank 2, a waste gas recovery tank 3, a first heat exchanger 4, a first reboiler 5, a first Adsorber 6, second adsorber 7, second heat exchanger 8, second reboiler 9, third reboiler 10, product storage tank 11, vaporizer 12, vapor-liquid separator 13, for the recovery of impurities The heat exchanger 14, the impurity recovery tank 15, the heating medium supplier 16, etc. are comprised.

[0032] The tank truck 1 for supplying the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com