Olefin preparation method comprising reduction pretreatment

A pretreatment, olefin technology, applied in chemical instruments and methods, catalyst activation/preparation, dehydrogenation to hydrocarbons, etc., can solve the problems of unfavorable overall process performance, low selectivity, low catalyst life process stability, etc. The number of compressor stages, the effect of saving energy costs and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

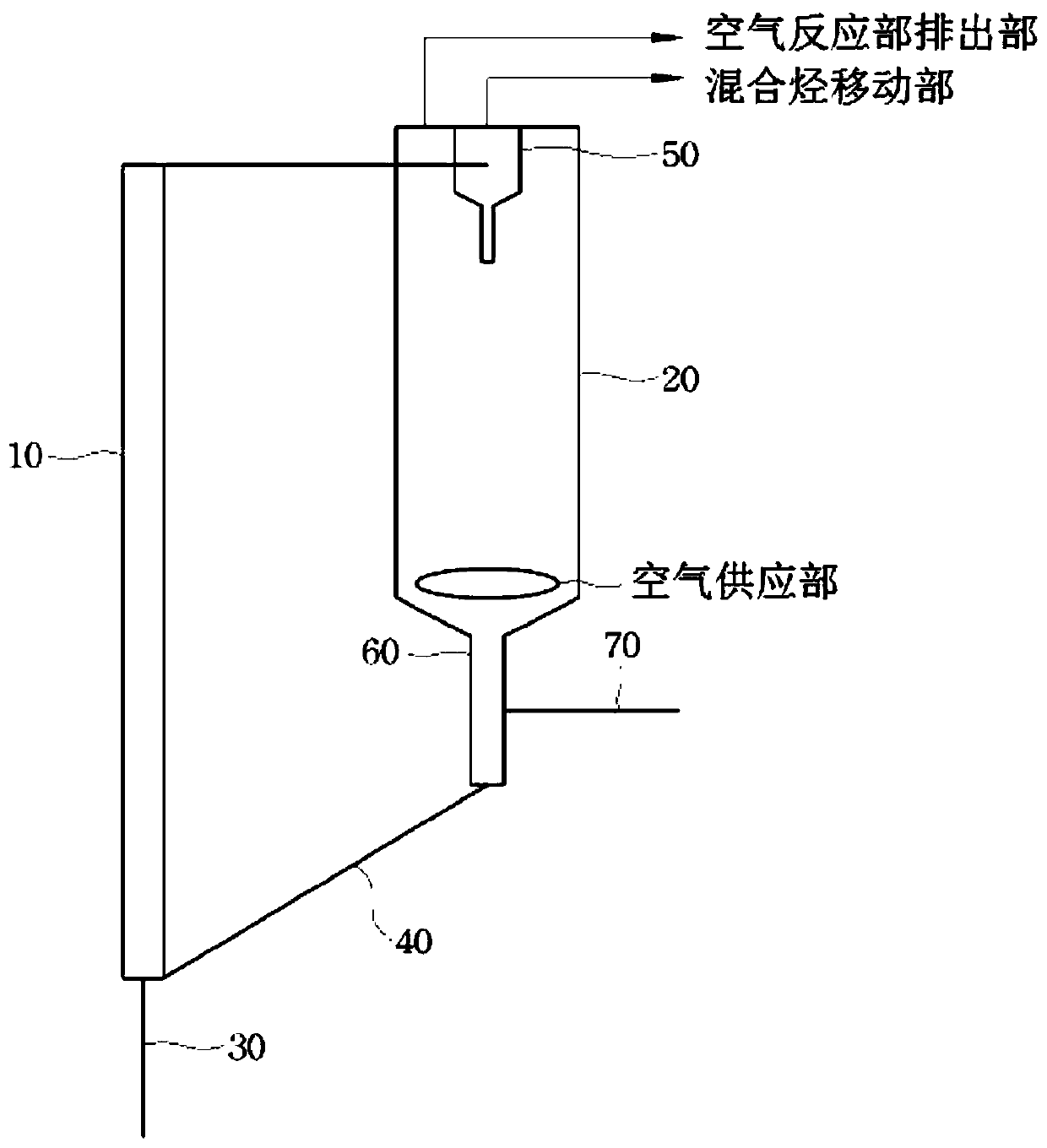

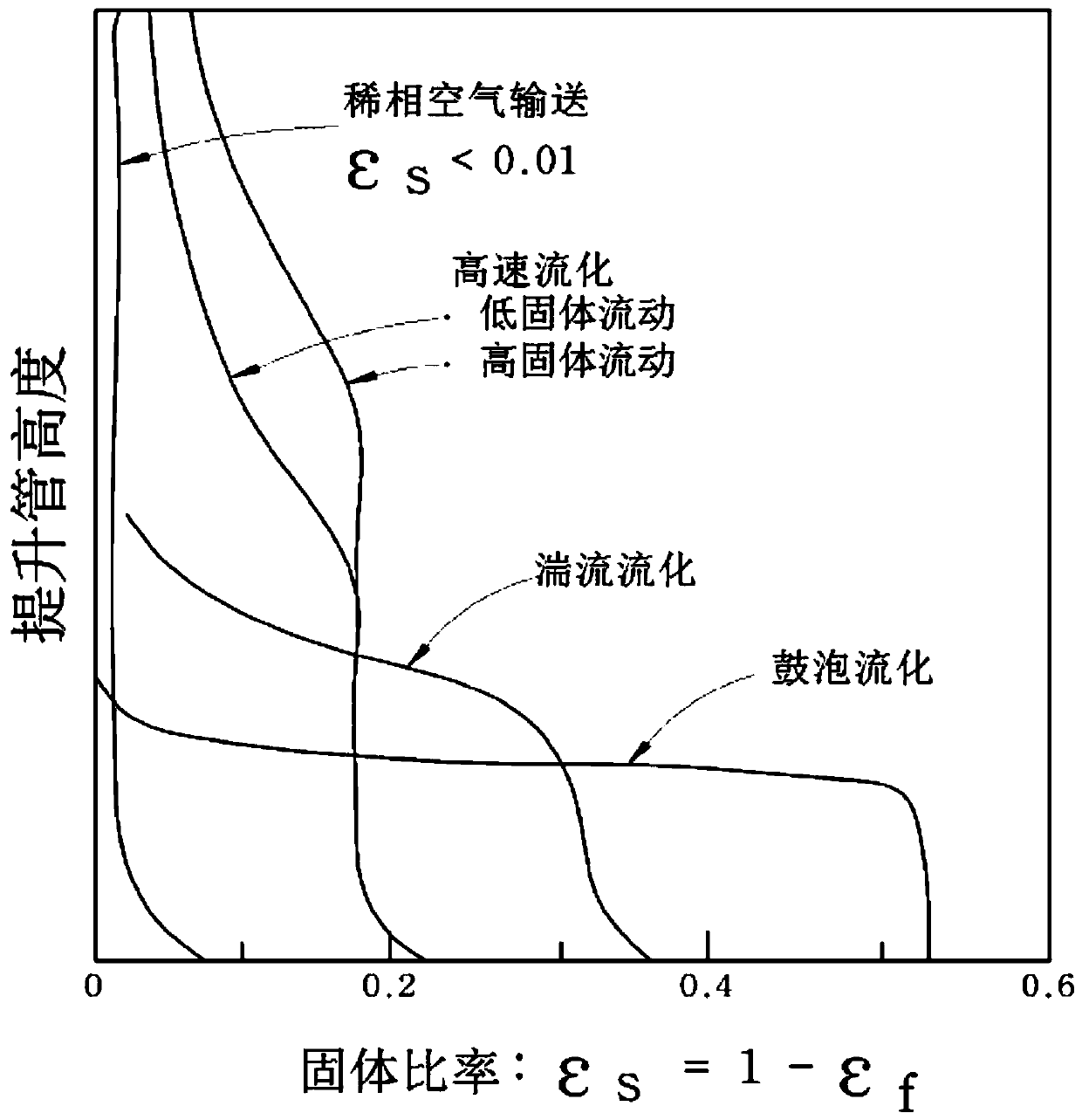

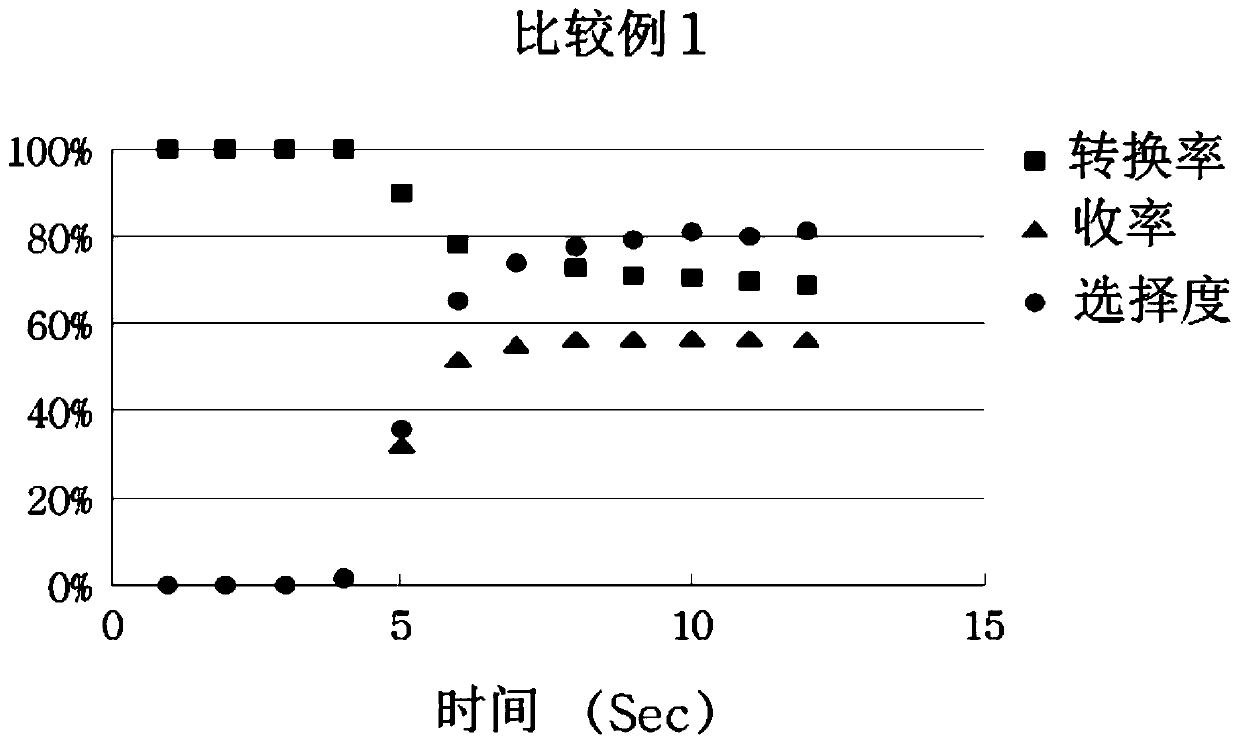

[0058] The production process of the invention relates in particular to a dehydrogenation process for the production of olefins from hydrocarbons. In particular, the production method of the present invention can be used in the process of producing propylene by dehydrogenating propane. At this time, when preparing the olefins, a catalyst, especially a metal oxide catalyst, is usually used. In the prior art, when the olefins were prepared from hydrocarbons through the catalyst, the temperature of the catalyst showed a sharp change in the initial stage of the reaction with the reaction time. increasing trend, followed by a gradual decrease in temperature.

[0059] At this time, when considering the change in catalyst temperature over time, the conversion rate, and the selectivity of olefins, the conversion rate reaches 100% in the early stage of the reaction when the catalyst temperature is increased, but most of the carbon dioxide is produced by the oxidation reaction of the hy...

Embodiment 1

[0111] Olefin Preparation 1

[0112] Step 1: Before the catalyst prepared above is supplied to the reaction section through the catalyst supply section, hydrogen (H 2 ) is supplied to the catalyst pretreatment section through the reducing gas supply section, and the temperature of the catalyst passing through the catalyst supply section is increased by 10 to 40°C to about 640 to 660°C due to the pretreatment.

[0113] Step 2: The catalyst heated up in the step 1 was supplied to the riser so as to have a space velocity (WHSV: ml / gcat.hr) 4240, and propane was supplied to the riser through the hydrocarbon supply to produce propylene.

[0114] Step 3: The catalyst reacted with the propylene prepared in the step 2 is separated in the separation part to obtain propylene, and the reacted catalyst is resupplied to the regenerator for regeneration.

[0115] Step 4: The catalyst regenerated in the regenerator is supplied to the riser after the process of step 1 is repeated.

Embodiment 2

[0116] Olefin Preparation 2

[0117] In step 1 of Example 1 of the present invention, the reduction time was changed to 300 seconds, and the space velocity (WHSV: ml / gcat.hr) was changed to 8400, except that it was performed in the same manner as in Example 1 to prepare Propylene.

[0118] When hydrogen is supplied as a reducing gas, the temperature of the catalyst in the propane dehydrogenation reaction is measured, the more the amount of hydrogen required for the pretreatment of the active oxygen carrier increases, the temperature of the catalytic bed due to the rapid combustion reaction at the initial stage of the reaction in the dehydrogenation reaction The more the increase decreases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com