Supergravity device for reduced pressure distillation and application method

A technology of vacuum distillation and supergravity, which is applied in the separation and purification of high-viscosity heat-sensitive materials, high-gravity devices, and separation of heat-sensitive materials. The effect of high quality, high efficiency and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

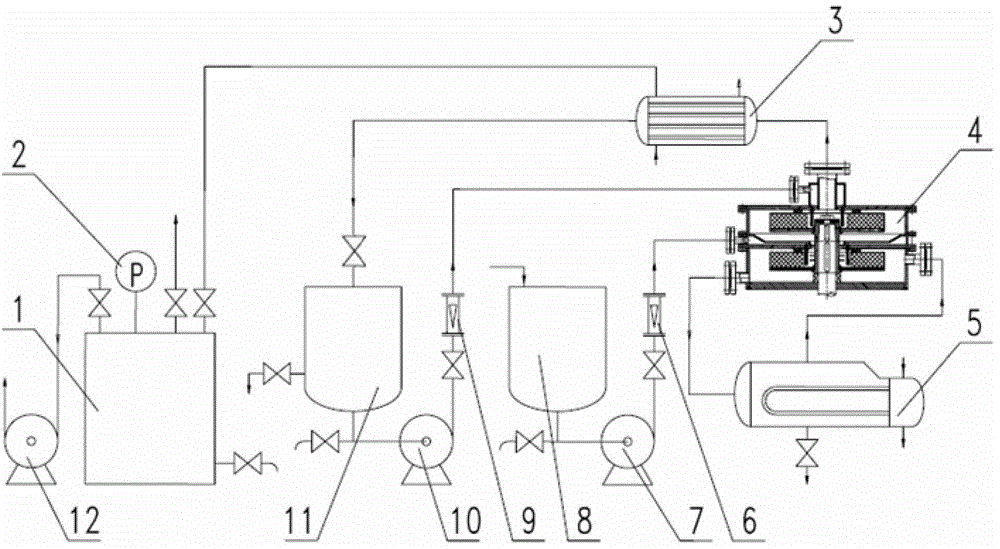

[0045] Embodiment 1: the vacuum distillation separation of ethanol and Virahol

[0046] Using foamed silicon carbide corrugated structured packing with an inner diameter of 100mm, an outer diameter of 300mm, and a height of 40mm, add 60L of ethanol-isopropanol solution with a viscosity of 0.2PaS and a molar ratio of 1:2 to the raw material tank 8, first turn on the vacuum pump 12, and vacuumize The temperature is 700mmHg (93000Pa); open the multi-stage high-gravity rectification machine 4, and gradually adjust the rotating speed to 300rpm; powered by the second pressure pump 7, measured by the second rotameter 6, and about 30L in the raw material tank 8 The ethanol-isopropanol solution is injected into the reboiler 5 through the multi-stage high-gravity rectification machine 4, and the second pressure pump 7 is closed; Heating is carried out to make it boil; the ethanol-isopropanol mixed steam after boiling is condensed by condenser 3 and enters condensation tank 11, after the...

Embodiment 2

[0047] Embodiment 2: the continuous vacuum distillation separation of heat-sensitive materials octanoic acid, capric acid and dodecanoic acid

[0048] Use nickel foam structured packing with an inner diameter of 150 mm, an outer diameter of 350 mm, and a height of 50 mm to add 50 L of octanoic acid, 0.46 capric acid and 0.01 dodecanoic acid solution with a viscosity of 2 PaS and a molar ratio of 0.53 to the raw material tank 8, and first turn on the vacuum pump 12 , the vacuum degree in the pumping tower is 18.75mmHg (2500Pa); Open the multi-stage ultra-gravity rectification machine 4, and gradually adjust the rotating speed to 1000rpm; Power is provided by the second pressure pump 7, and the second rotameter 6 measures, and the raw material The three-component mixed solution of about 25L in the tank 8 is poured into the reboiler 5, and the second pressure pump 7 is turned off; high-temperature steam is passed into the heat exchange tube of the reboiler 5 to heat the material i...

Embodiment 3

[0049] Embodiment 3: the vacuum distillation separation of thermosensitive material sterol, peach aldehyde

[0050] Use the foam silicon carbide corrugated structured packing with an inner diameter of 20mm, an outer diameter of 100mm, and a height of 20mm to add 60L of a sterol-peach aldehyde solution with a viscosity of 200PaS and a molar ratio of 1:2 into the raw material tank 8, and first turn on the vacuum pump 12, and the vacuum degree is 700mmHg (93000Pa); open the multi-stage high-gravity rectifier 4, and gradually adjust the rotating speed to 300rpm; powered by the second pressure pump 7, the second rotameter 6 measures, and the sterol of about 30L in the raw material tank 8- The peach aldehyde solution is injected into the reboiler 5 through the multi-stage high-gravity rectification machine 4, and the second pressure pump 7 is closed; high-temperature water vapor is passed into the heat exchange tube of the reboiler 5 to heat the material in the reboiler 5, Make it b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com