Thermal coupling power generation system of garbage incinerator medium pressure steam and coal-fired unit

A technology for waste incinerators and coal-fired units, which is applied to steam engine devices, machines/engines, mechanical equipment, etc. It can solve problems such as low dioxin smoke emission indicators, low unit efficiency, low-temperature corrosion at the tail, and achieve system savings Equipment and operating costs, reducing coal consumption for power generation, and increasing the temperature of feed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

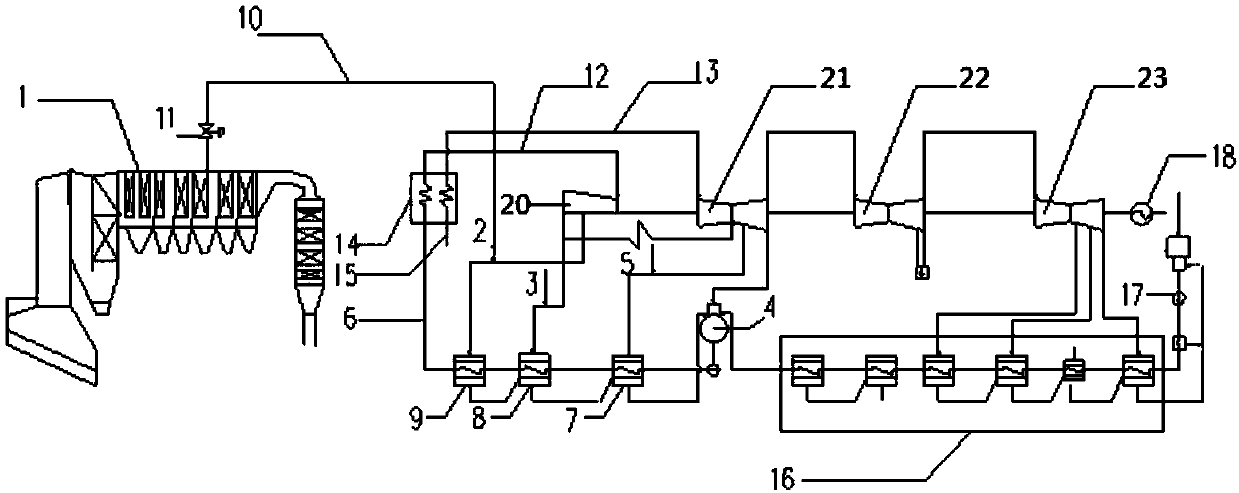

[0022] refer to figure 1 , the thermodynamically coupled power generation system of medium-pressure steam of the waste incinerator and the coal-fired unit, including the waste furnace body 1, the feed water pump 17, the low-pressure heater 16, the deaerator 4, the high-pressure heater, the water supply pipeline 6, and the coal-fired unit 14. Main steam pipeline 12, reheater pipeline 13, ultra-high pressure cylinder 20, high pressure cylinder 21, condenser 18, primary steam extraction pipeline 2 and secondary steam extraction pipeline 3, and the high pressure heater includes interconnected The first-level high-pressure heater 7 and the second-level high-pressure heater 8, the ultra-high pressure cylinder 20 is connected to the high-pressure cylinder 21, the feed water pump 17 is connected to the low-pressure heater 16 through the pipeline, and the low-pressure heater 16 is connected to the deaerator 4 through the pipeline, The deaerator 4 is connected to the high-pressure heate...

Embodiment 2

[0027] The steam outlet of the garbage furnace body 1 is connected to the secondary steam extraction pipeline 3 through a pipeline 10 .

Embodiment 3

[0029] The steam outlet of the garbage furnace body 1 is connected with the deaerator 4 through the pipeline 10 .

[0030] work process:

[0031] The feed water enters the low-pressure heater 16 through the feed water pump 17, and then enters the third-stage high-pressure heater 7, the second-stage high-pressure heater 8, and the first-stage high-pressure heater 9 through the deaerator 4, and then is sent into the large coal-fired boiler through the water supply pipeline 6. Unit 14, the high-temperature and high-pressure main steam generated by the combustion of the coal-fired unit 14 enters the ultra-high pressure cylinder 20 through the main steam pipeline 12 to perform work, wherein the steam extracted from the ultra-high pressure cylinder 20 is used to heat the secondary high-pressure heater 8 and the tertiary The high-pressure heater 7 and most of the exhaust gas from the ultra-high-pressure cylinder 20 enter the reheater system 15 of the coal-fired unit 14, and the rehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com