Gas-steam circulation heating-electricity-cooling combined supply system and method for thermal power plant with zero energy loss rate

A technology of loss rate and thermal power plant, which is applied in the field of combined heating, power and cooling of combustion-steam combined cycle, and can solve the problems of loss of energy saving and economy, immaturity, and large power consumption for transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

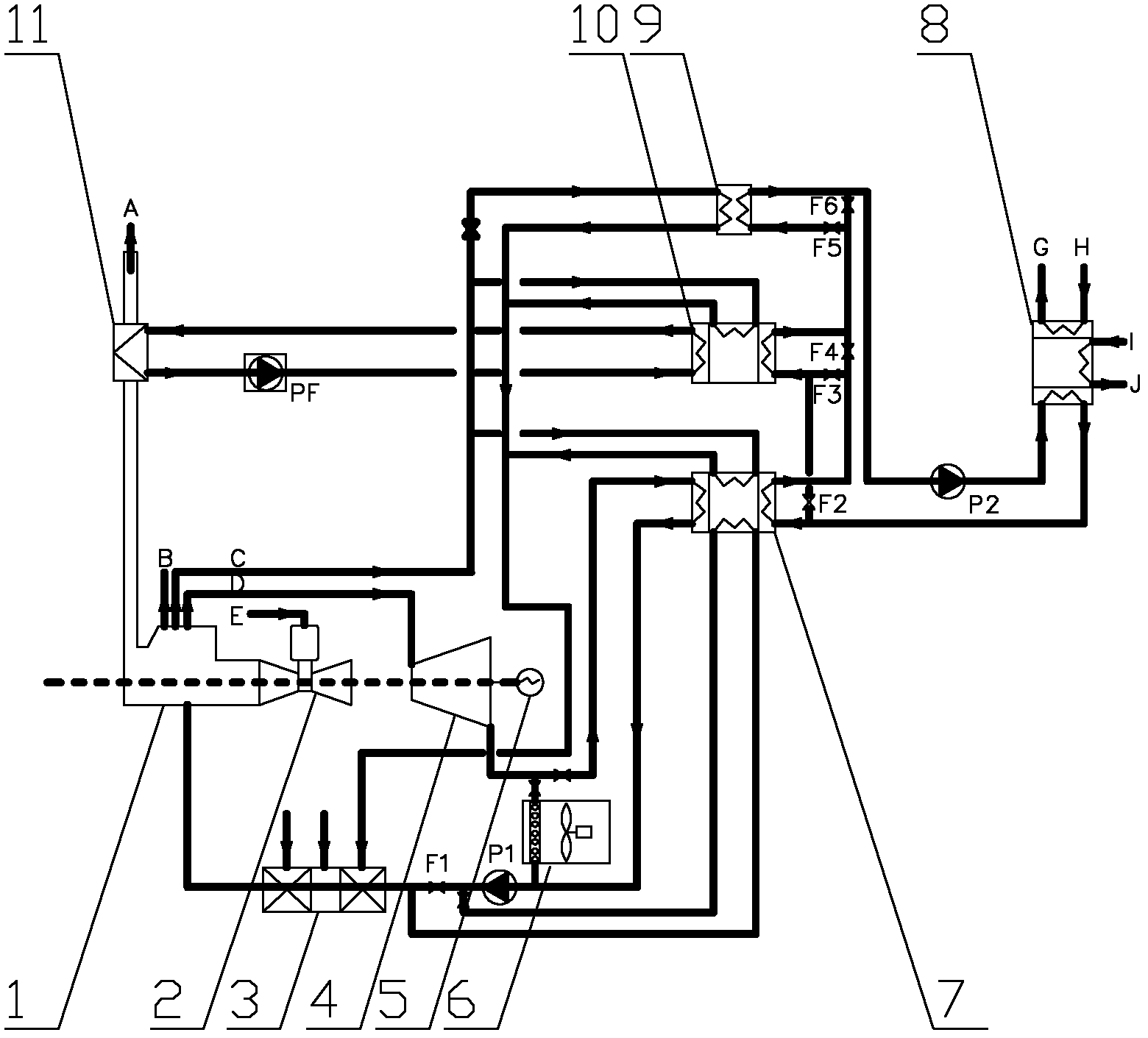

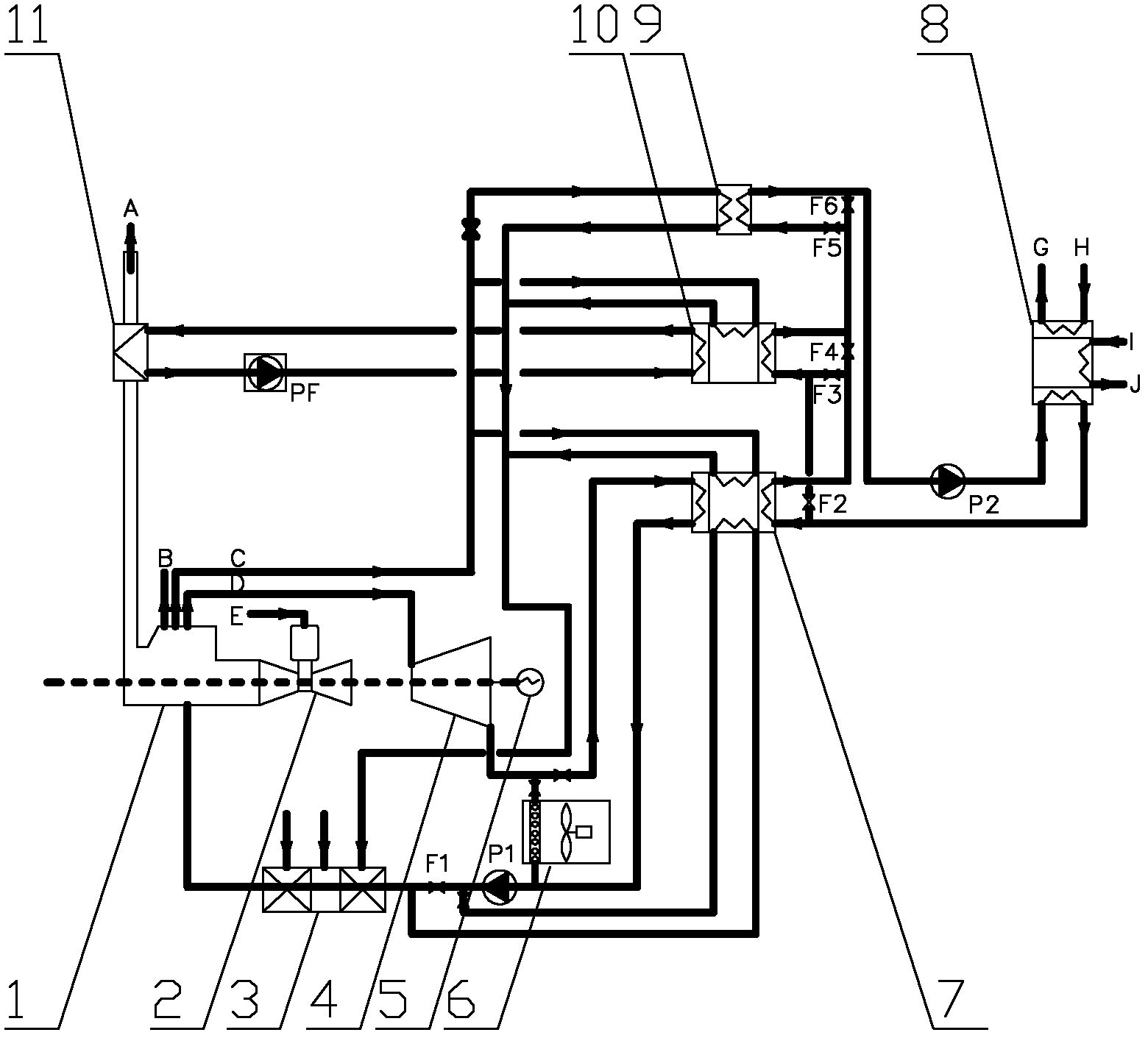

[0021] The system of the present invention is described in detail as follows in conjunction with accompanying drawings and embodiments:

[0022] Combustion-steam cycle combined heat, electricity and cooling system and method proposed by the present invention for thermal power plant with zero energy loss rate The structure is as follows figure 1 As shown, it includes a gas turbine 2, a waste heat boiler 1, a steam turbine 4, a generator 5, a boiler feed water heater group 3, an air-cooled or water-cooled condenser 6, and various power equipment connected to each equipment to form an overall system , the energy transmission and distribution pipeline network composed of electric valves and the operation control network composed of computers, temperature, pressure and flow sensors (belonging to the prior art, not shown in the figure), it is characterized in that the system also includes a large temperature difference absorption type Exhaust steam recovery heat pump 7, large temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com