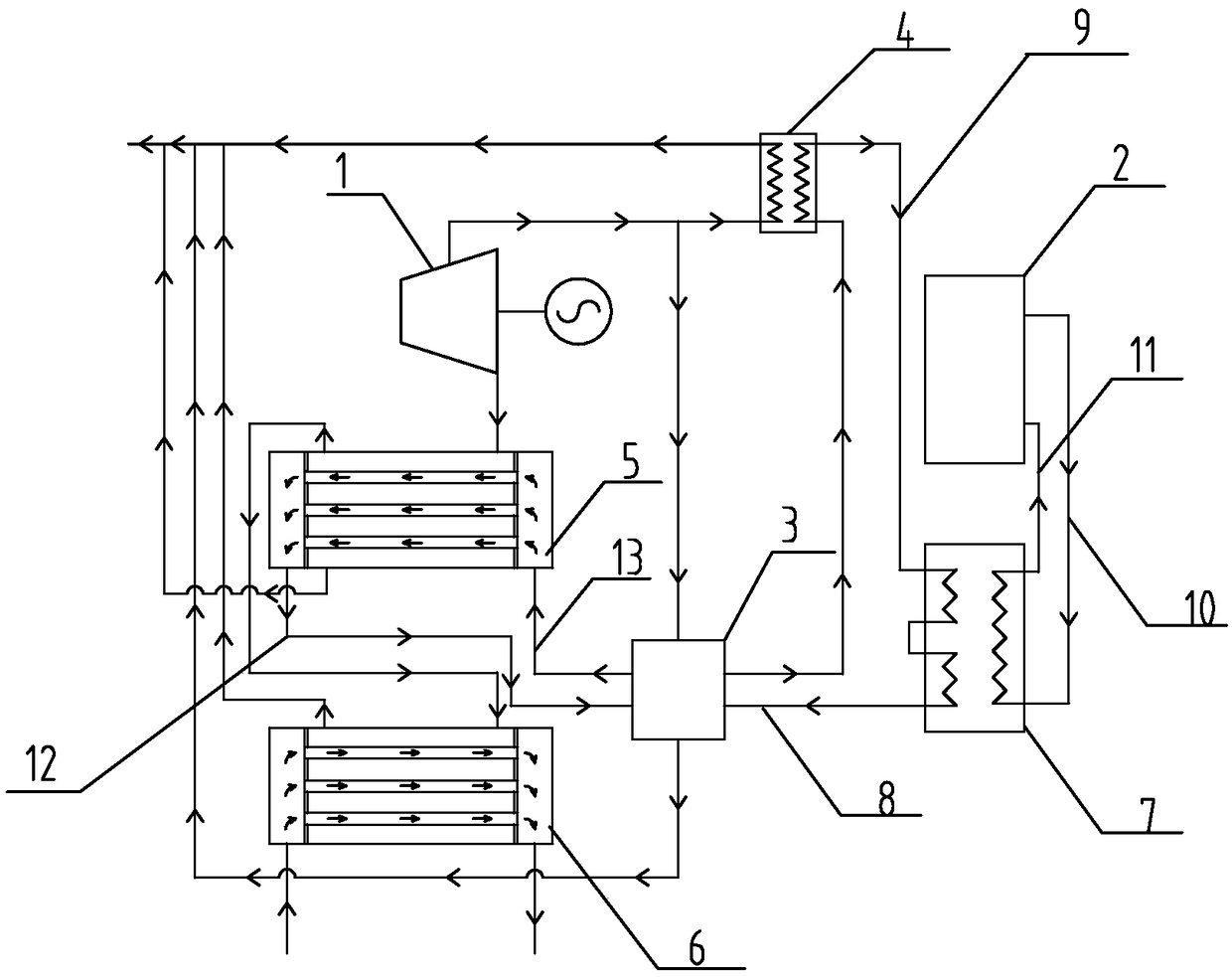

Large-temperature-difference centralized heat supply system adopting double condensers

A technology of central heating and double condensers, which is applied in hot water central heating systems, heating systems, household heating, etc., to achieve the effects of maintaining safe and stable operation, efficiently returning waste heat from steam turbines, and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In a thermal power plant, the high-temperature steam in the steam turbine (1) drives the generator to generate electricity; then the steam extraction in the middle section of the steam turbine (1) is divided into two parts, which are respectively used as a steam-water heat exchanger (4) and an absorption heat pump (3) unit The power source participates in heat exchange;

[0018] The primary network return water (8) flowing back from the large temperature difference heat exchange system (7) is transported to the absorption heat pump (3) as the low-temperature heat source of the heat pump, and then transported to the primary condenser (5) after heat exchange and cooling The tube side is used to cool and condense the exhaust steam of the steam turbine (1) flowing through the shell side of the primary condenser (5), and the cooling water outlet (12) after heat exchange between the cooling water and the exhaust steam is input into the absorption heat pump (3), After being he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com