Absorption-type large-temperature-difference heat exchange unit driven by low-temperature hot water

A technology for low-temperature hot water and heat exchange units, which is applied to heating methods, boiler absorbers, and hot water central heating systems, etc., can solve the problems of lowering the temperature of the driving heat source, unsuitable absorption heat exchange units, and the unit cannot operate. Achieve the effect of increasing the temperature difference between the supply and return water, increasing the conveying capacity, and reducing the temperature of the return water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

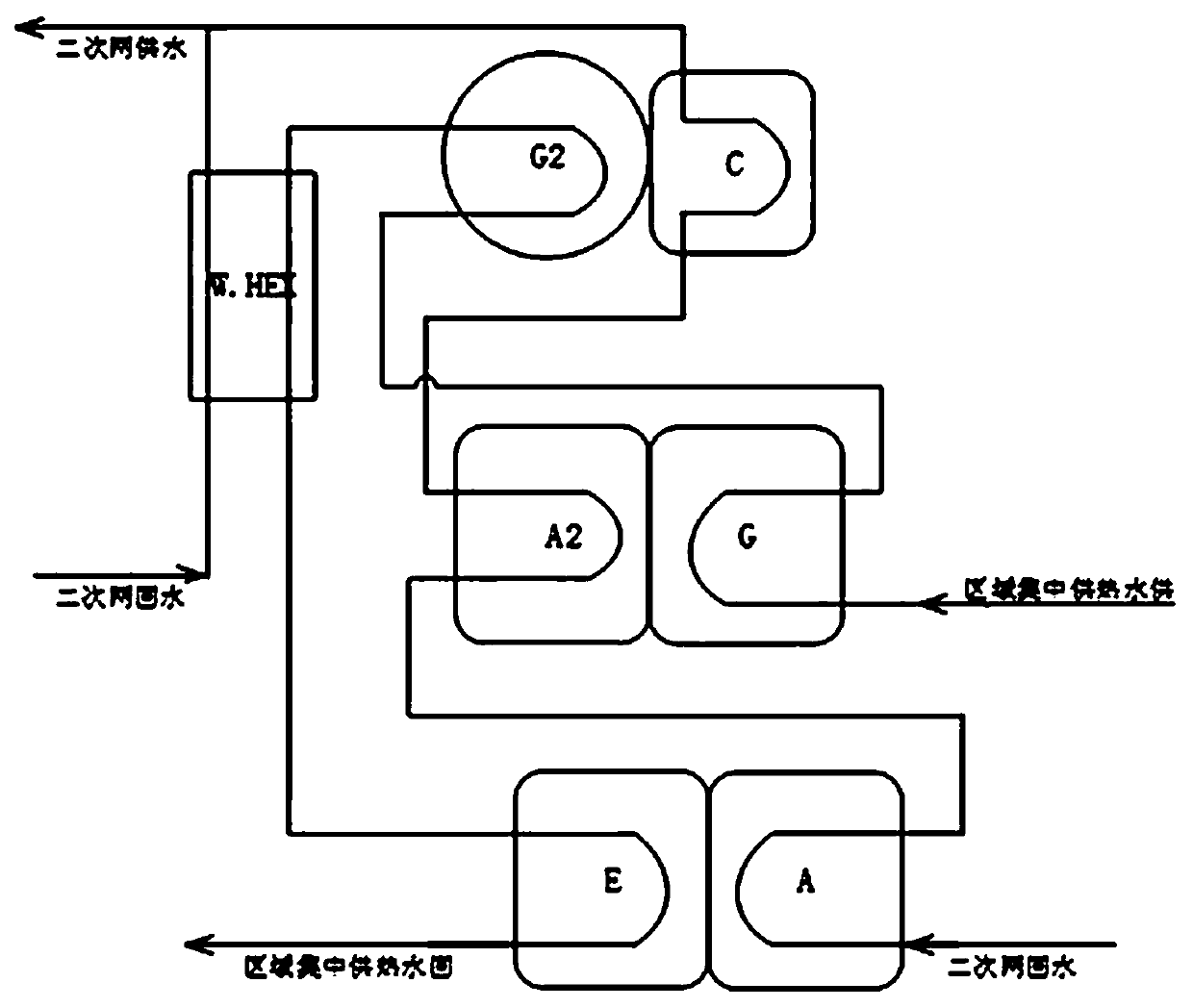

[0011] see figure 1 , the absorption type large temperature difference heat exchange unit driven by low-temperature hot water of the present invention includes a generator G2, a condenser C, a low-pressure absorber A, an evaporator E, a high-pressure absorber A2, a high-temperature generator G and a water-water plate heat exchanger W .HEX. Low-pressure absorber A and evaporator E form a low-pressure cylinder, high-pressure absorber A2 and high-temperature generator G form a medium-pressure cylinder, generator G2 and condenser C form a high-pressure cylinder, and the low-pressure cylinder and medium-pressure cylinder are arranged separately Or overall arrangement. The circulation system of the unit of the present invention is divided into an external pressurized water circuit and an internal vacuum circuit. The external pressurized waterway is divided into primary network waterway and secondary network waterway. The primary network waterway passes through high-temperature gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com