Novel combined heat dissipation terminal system

A new type of export-side technology, applied in the field of new combined heat dissipation terminal system, can solve the problems of reduced heat supply coefficient of air conditioning units, difficulty in large-scale promotion and use, and high operating costs, so as to reduce circulation flow and circulation pump power consumption, and save energy Significant benefits and reduced operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

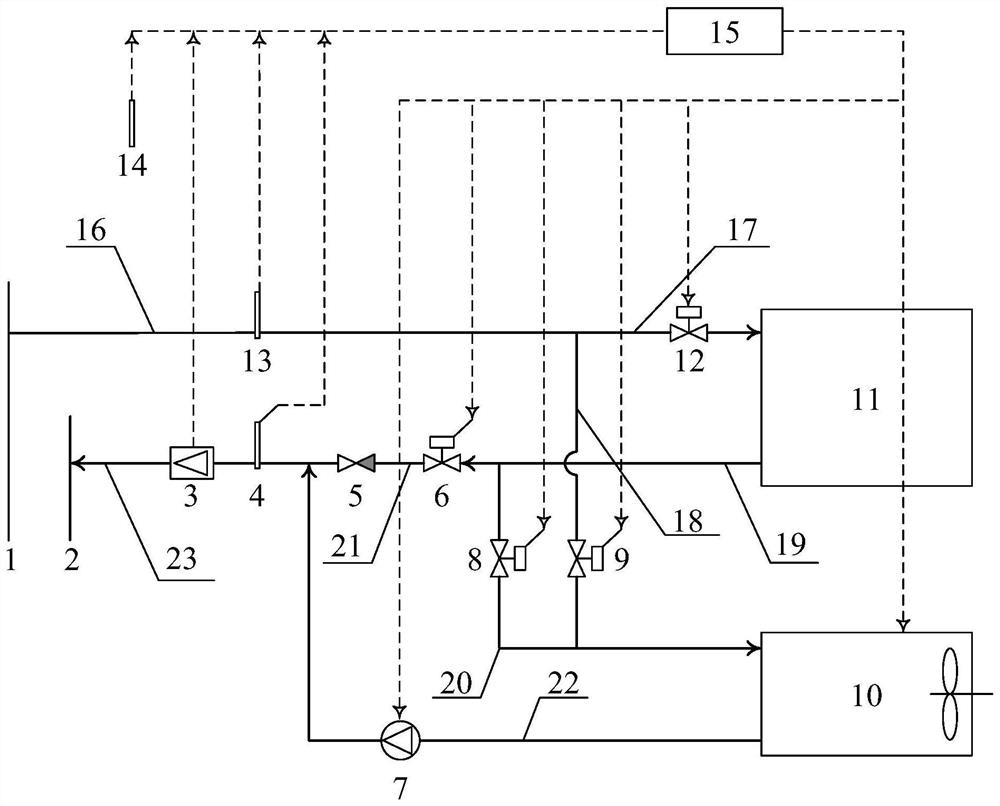

Method used

Image

Examples

Embodiment 1

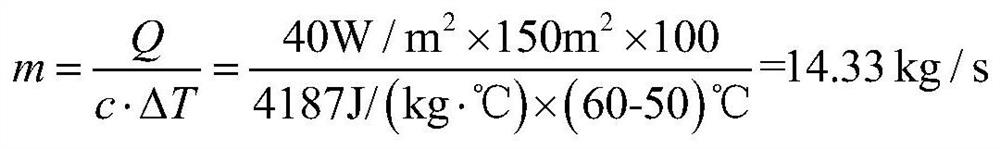

[0032] The use of this system can increase the temperature difference between the secondary network supply and the return water, and bring significant energy-saving benefits.

[0033] Suppose a heating power station supplies heat to 100 building users through the secondary network, and each household has a heating area of 150m 2 , The design heat index is 40W / m 2 ; At the same time, suppose that the design supply and return temperature of the secondary network is 60 / 50℃ (temperature difference 10℃).

[0034] Under the above calculation conditions, the mass flow rate of the circulating pump in the secondary network of radiant floor heating is:

[0035]

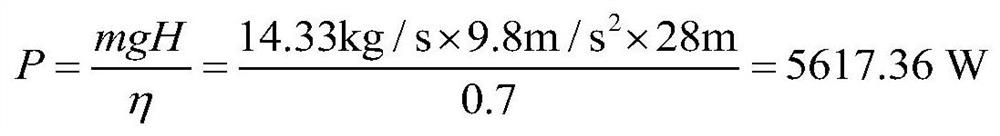

[0036] Assuming that the head of the secondary network circulating pump is 28m and the mechanical efficiency is 0.7, the electric power of the circulating pump is:

[0037]

[0038] When the system of the present invention is adopted and the third operating state of the radiation and convection hybrid heating mode is adopted, the retu...

Embodiment 2

[0043] Compared with conventional air source heat pump air conditioners and electric heaters, the electrically driven heat pump heater 10 in this system has the smallest energy consumption under the same heat output condition, and has a significant energy saving effect.

[0044] If 40% of the heat load of a building user is borne by electric-driven heat pump heaters, air source heat pump air conditioners or electric heaters (total heating power is 40W / m 2 ×150m 2 ×40%=2400W); assuming that the condensing temperature of the electrically driven heat pump heater and the air source heat pump air conditioner are both 50℃, the evaporation temperature is 5℃ and -15℃, and the mechanical efficiency is 60%, then the two types of equipment The ideal Carnot cycle heating coefficients are with The actual heating coefficients are 4.3 and 3.0 respectively. Therefore, the electric power of the electrically driven heat pump heater is The electric power of the air source heat pump air conditione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com