Coal economizer for power station boiler

A technology for power plant boilers and economizers, which is applied to feed water heaters, lighting and heating equipment, steam generation, etc., can solve problems such as no temperature adjustment function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following examples.

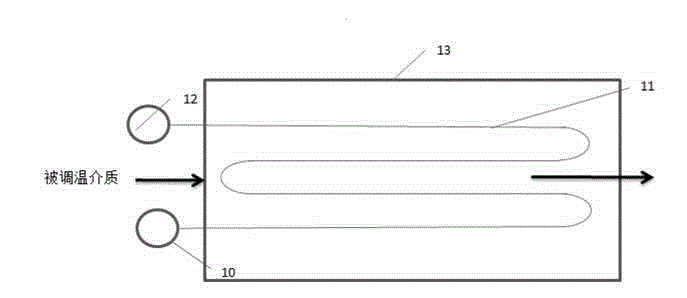

[0022] The economizer system includes: the inlet header of the economizer, the heating surface of the economizer, the outlet header of the economizer, and the outlet pipeline of the economizer. The water supply pipe is connected to the inlet of the economizer inlet header.

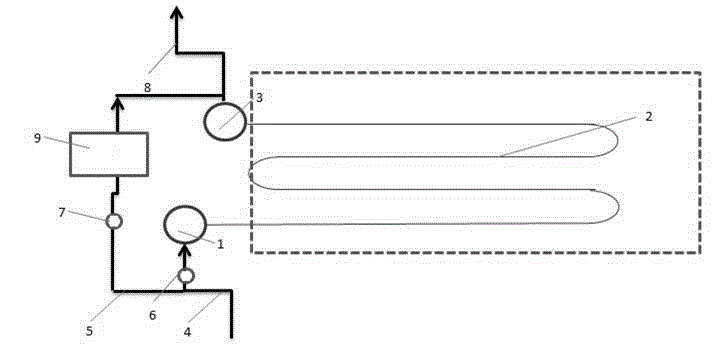

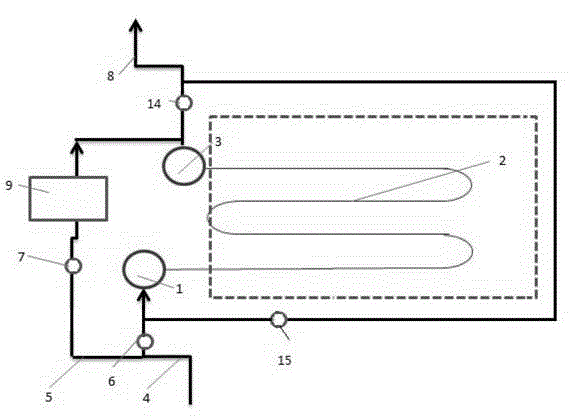

[0023] figure 1 The dotted line area is a conventional economizer system, which can be a parallel, series or series-parallel combination system. The area surrounded by a dotted line may not only be the heating surface of the economizer, but also include headers and pipelines.

[0024] The process of the first bypass pipeline 5 starts from the water supply pipeline 4, and the process returns to the outlet pipeline 8 of the economizer. The actual process is not limited to this. After the process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com