Hot-pressing type ultra supercritical unit number-zero high-pressure heater and switching system thereof

A technology of ultra-supercritical unit and switching system, which is applied in the field of hot-pressed ultra-supercritical unit zero high-intensity and its switching system. problem, to achieve the effect of reducing the outlet smoke temperature, increasing the feed water temperature, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

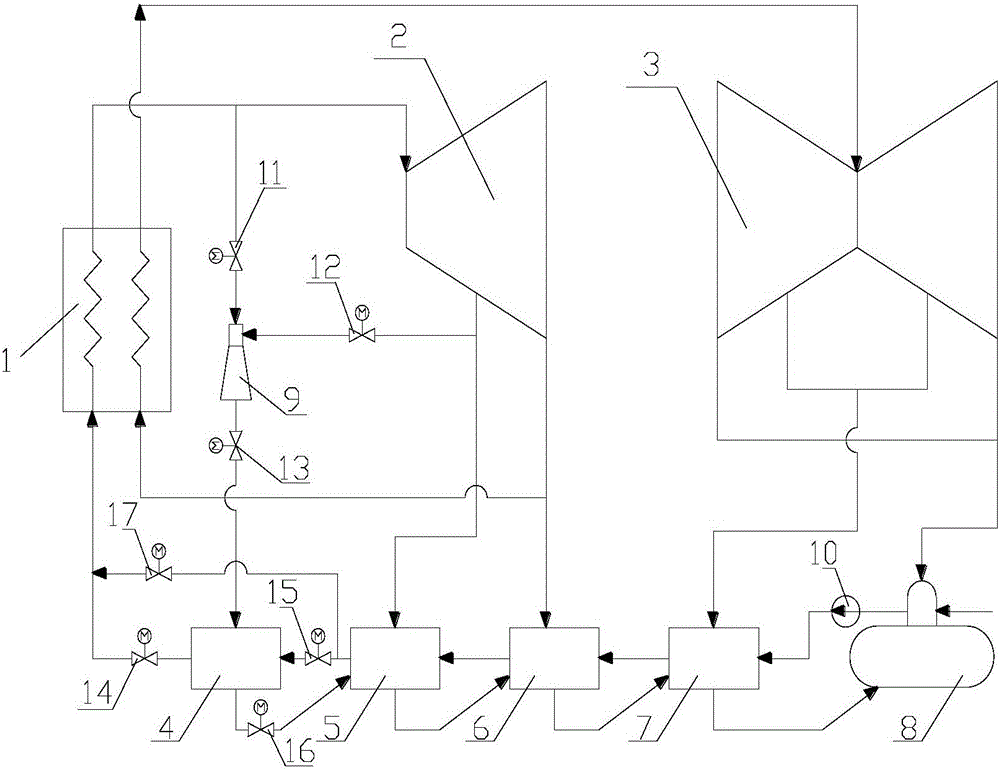

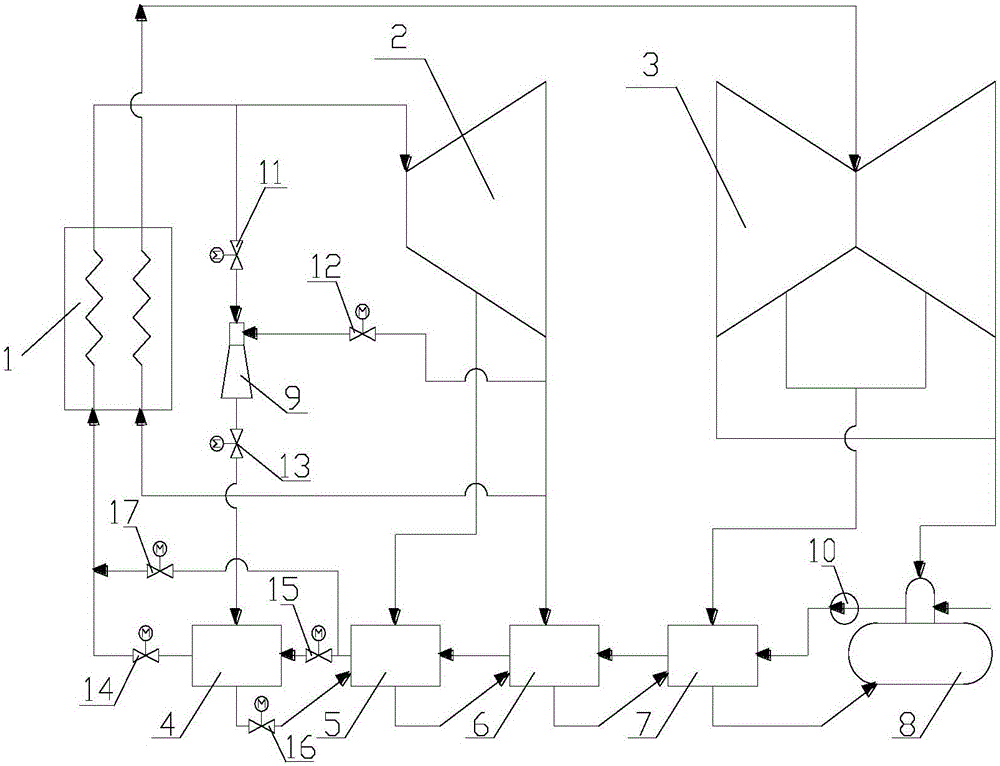

Image

Examples

Embodiment example

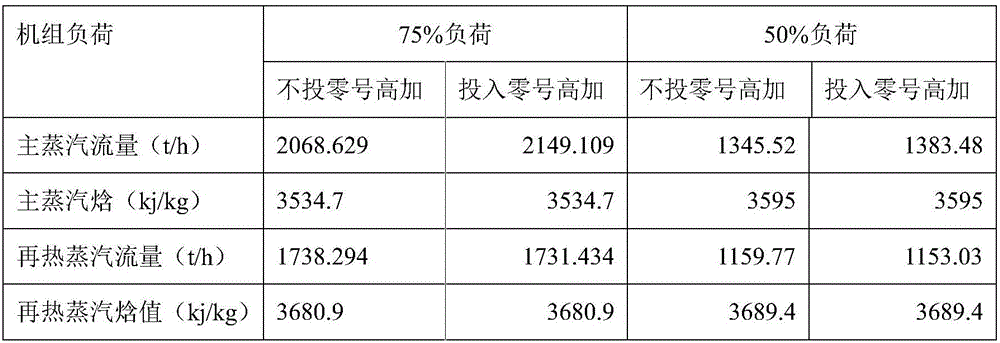

[0045] Taking a 1000MW ultra-supercritical unit in a power plant as an example, the power steam of the hot press is taken from the main steam, and after a section of steam is pumped, the mixed steam enters the No. 0 high-pressure heater. The previous thermal parameters of the unit are as follows: The table below It shows that the heat consumption after putting into No. 0 high-speed heating is reduced by 29kj / (kW.h) under the condition of 75% load, and is reduced by 32kj / (kW.h) under the condition of 50% load. Calculation of calorific value 29300kj / kg, under 75% load condition, the coal consumption of the unit for power generation is reduced by 1.075g / kWh, and under the condition of 50% load, the coal consumption of the unit for power generation is reduced by 1.186g / kWh. If the annual power generation in this load segment is calculated as 3 billion kWh, about 3,300 tons of standard coal can be saved each year, which has significant energy-saving and emission-reduction benefits...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com