Secondary reheating steam turbine generator unit system provided with overheating steam feed water heater

A technology of steam turbine generator set and feed water heater, which is applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of heating feed water capacity limitation, feed water temperature saturation temperature limitation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

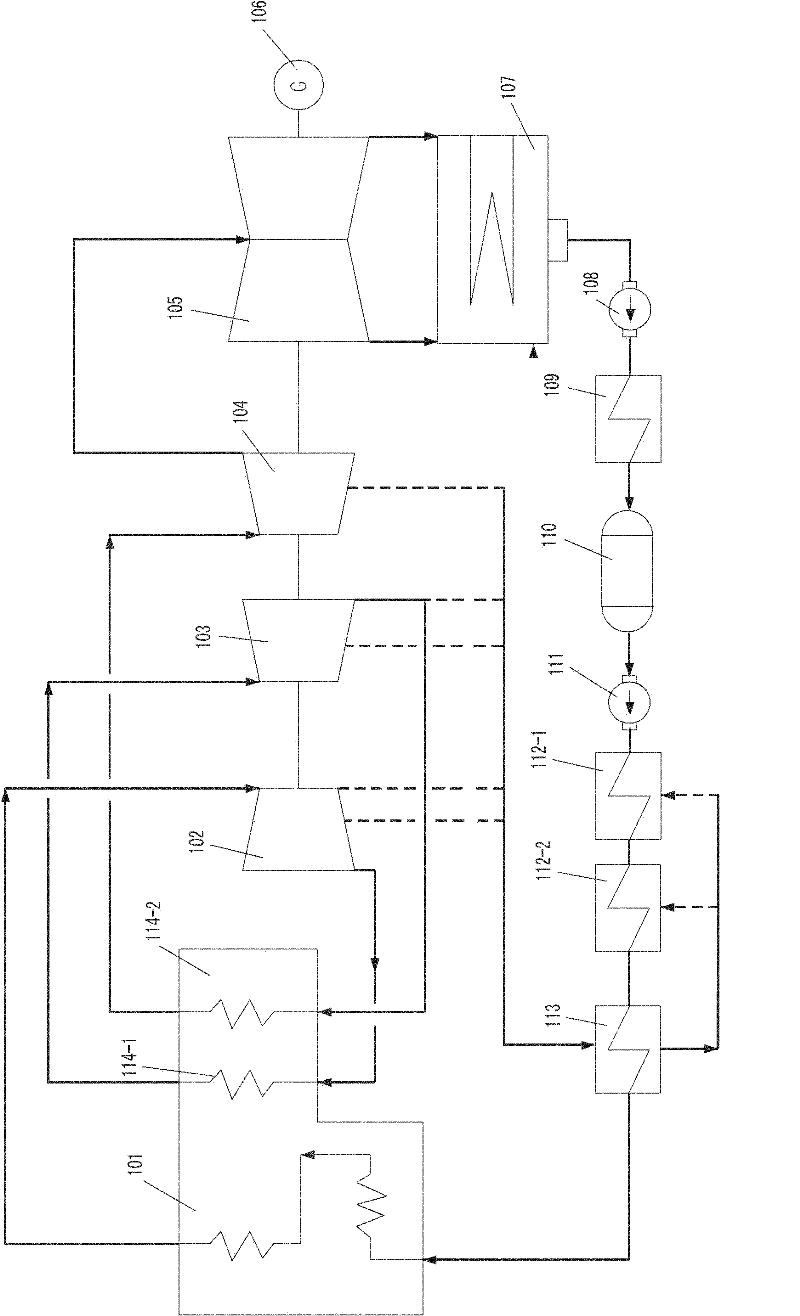

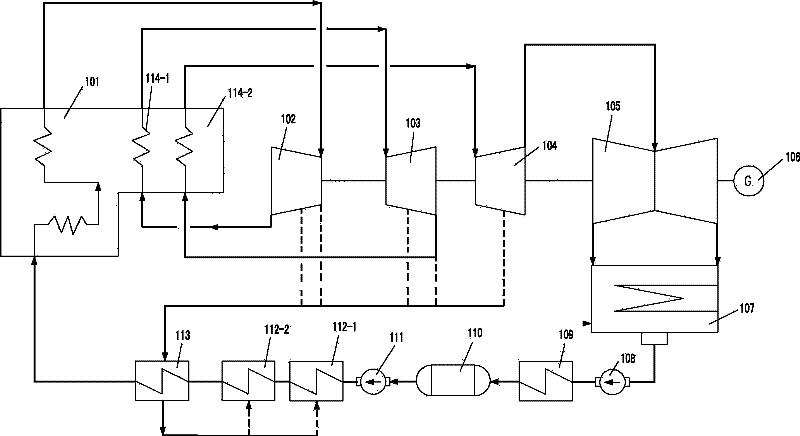

[0019] Such as figure 1 As shown, the twice-reheated turbogenerator set system with superheated steam feedwater heater of the present invention mainly includes the following components: boiler 101, steam turbine (comprising high-pressure cylinder 102, low-pressure medium-pressure cylinder 103, second medium-pressure cylinder 104, low pressure cylinder 105), generator 106, condenser 107, condensate pump 108, low pressure heater group 109, deaerator 110, feed water pump 111, high pressure feed water heater group 112-1 and 112-2 and superheated steam feed water heating Device group 113.

[0020] As shown in the figure, the turbogenerator set is single-shaft, that is, its high-pressure cylinder 102, first medium-pressure cylinder 103, second medium-pressure cylinder 104, low-pressure cylinder 105 and generator 106 are sequentially connected on the same shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com