Vessel atmospheric condenser, manufacturing method thereof and vessel closed cycle system

An atmospheric condenser and marine technology, applied in steam/steam condensers, lighting and heating equipment, preheating, etc., can solve problems such as complex equipment structure, corrosion of zinc blocks, troublesome operation, etc., to achieve small size and occupy an area The effect of small area and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

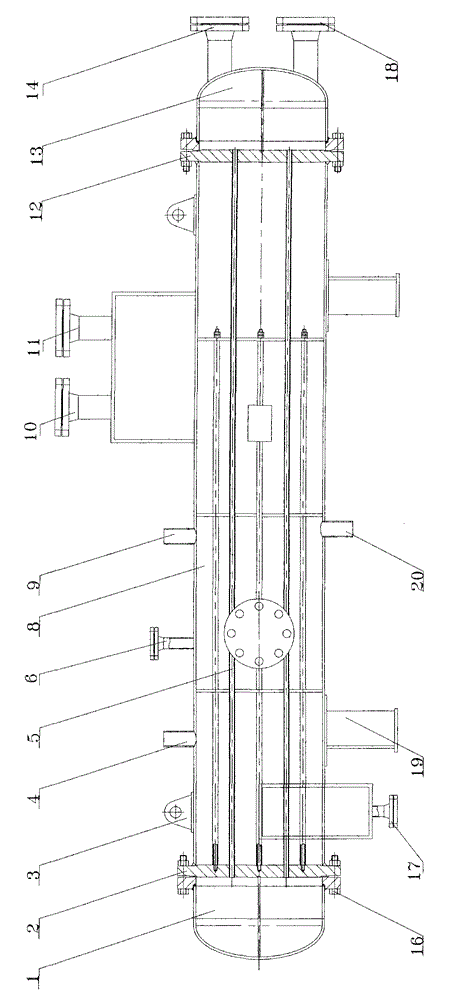

[0028] Example 1, such as figure 1 As shown, this embodiment discloses a marine atmospheric condenser, including a cylinder body 8, the front and rear ends of the cylinder body 8 are respectively provided with a front tube plate 2 and a rear tube plate 12, the front tube plate 2 and the front tube box 1 Connection, the rear tube plate 12 is connected with the rear tube box 13. The rear tube box 13 is provided with a water inlet 14 and a water outlet 16, and a heat exchange tube is provided in the cylinder 8, a steam inlet 10 and a steam outlet of the heat exchange tube 11. The condensate outlet 17 extends out of the surface of the cylinder. The inner side of the front tube box 1 and the rear tube box 13 are respectively provided with a plastic lining layer, the heat exchange tubes are arranged in an equilateral triangle, and the plastic lining layer is made of polytetrafluoroethylene. Hot-melt bonding layer of ethylene and stainless steel substrate. The material of the heat ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com