Cross-flow internally-cooled solution dehumidifier and method thereof

A solution dehumidification and cooling technology, applied in chemical instruments and methods, separation methods, heating methods, etc., can solve the problems of decreased dehumidification efficiency and increased temperature of dehumidification solution, and achieve the effect of reducing air side pressure and improving dehumidification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

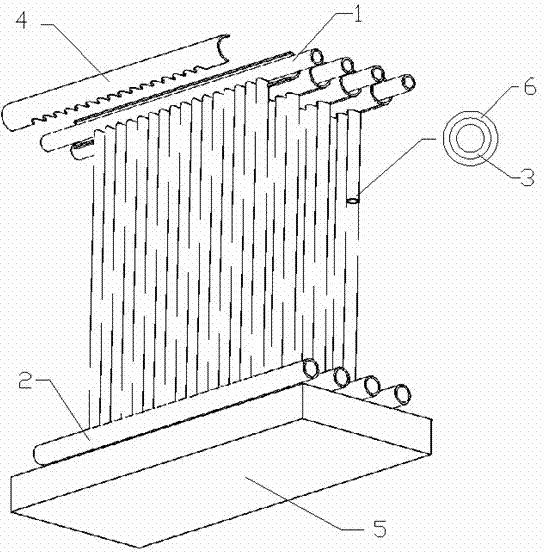

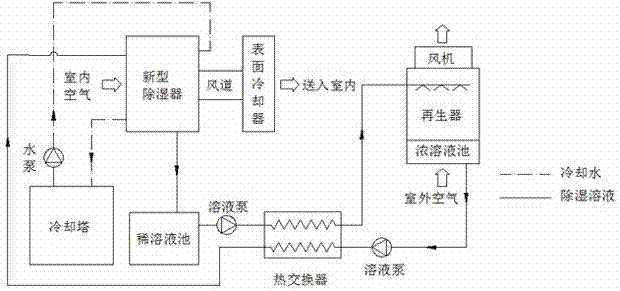

[0023] Air conditioning systems using cross-flow internally cooled solution dehumidifiers. The system is mainly composed of dehumidifier, regenerator, surface cooler, fan, cooling tower, dilute solution pool, concentrated solution pool, solution heat exchanger, heater, water pump, and solution pump.

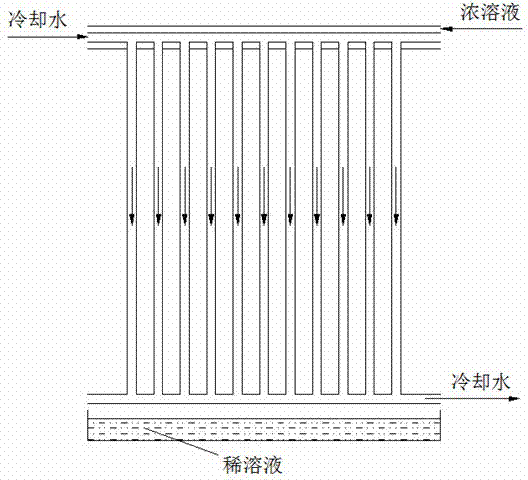

[0024] After the dehumidification solution flows into the casing, it will flow down the capillary and be evenly distributed outside the capillary by the capillary suction of the corduroy. When the humid air passes horizontally between the parallel plates, it contacts with the dehumidification solution and undergoes heat and mass transfer to complete the dehumidification process. The dilute solution that has absorbed water vapor and latent heat of vaporization is collected by the sump and flows out of the dehumidifier to the dilute solution pool, and then the solution is pumped to the heat exchanger to release heat. The dilute solution flowing out of the heat exchanger flows into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com