Multiple reaction integrated process for desulfuizing from fume by dry method and its system

A dry flue gas desulfurization and flue gas technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as complex system structure, human health hazards, and high operating costs, and achieve extended reaction space and reaction time, improve desulfurization efficiency, and increase the effect of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

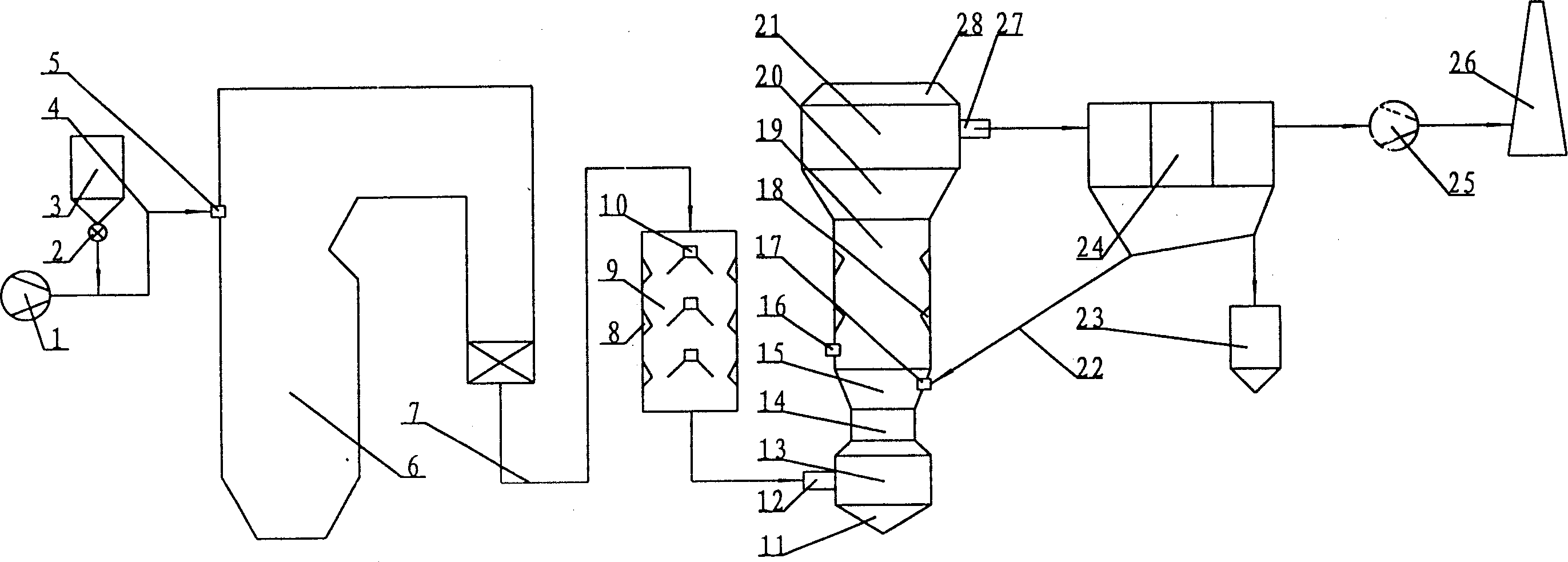

[0024] The following is a further detailed description of the multi-reaction integrated dry flue gas desulfurization process and its system of the present invention for a coal-fired power plant boiler in conjunction with the accompanying drawings:

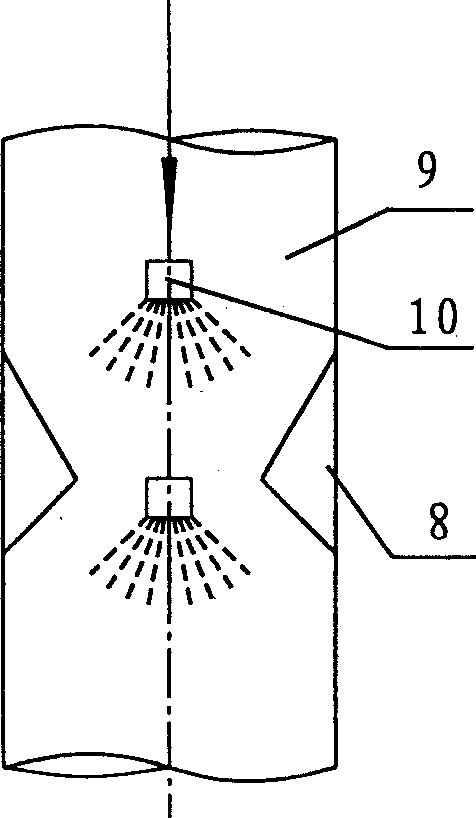

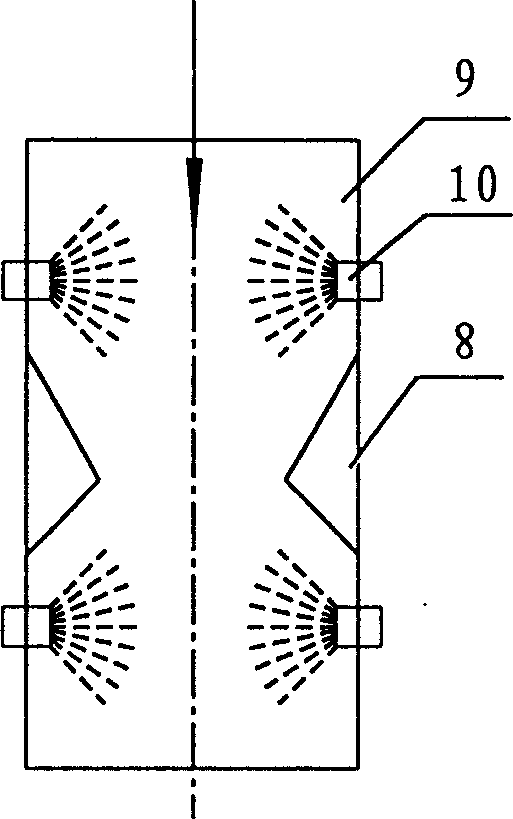

[0025] The multi-reaction integrated dry flue gas desulfurization system shown in the figure is mainly composed of a limestone powder injection device, a humidifying flue 9, a desulfurization tower 28, External electrostatic precipitator 24, induced draft fan 25 and chimney 26 etc. constitute.

[0026]The limestone powder injection device consists of a limestone powder bin 3, a rotary powder feeder 2 installed at the lower end of the limestone powder bin 3, a compressor 1 connected to the rotary powder feeder 2 through a powder delivery pipeline 4, and a powder feeder installed at the end of the powder delivery pipeline 4. Limestone powder nozzle 5 composition. The limestone powder nozzle 5 is arranged above the furnace of the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com