Method and device for operating internal combustion engine having throttle valve and exhaust gas recirculation system for detecting carbon-deposited AGR line

A technology of exhaust gas recirculation and exhaust gas recirculation valve, which is used in exhaust gas recirculation, internal combustion piston engine, charging system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

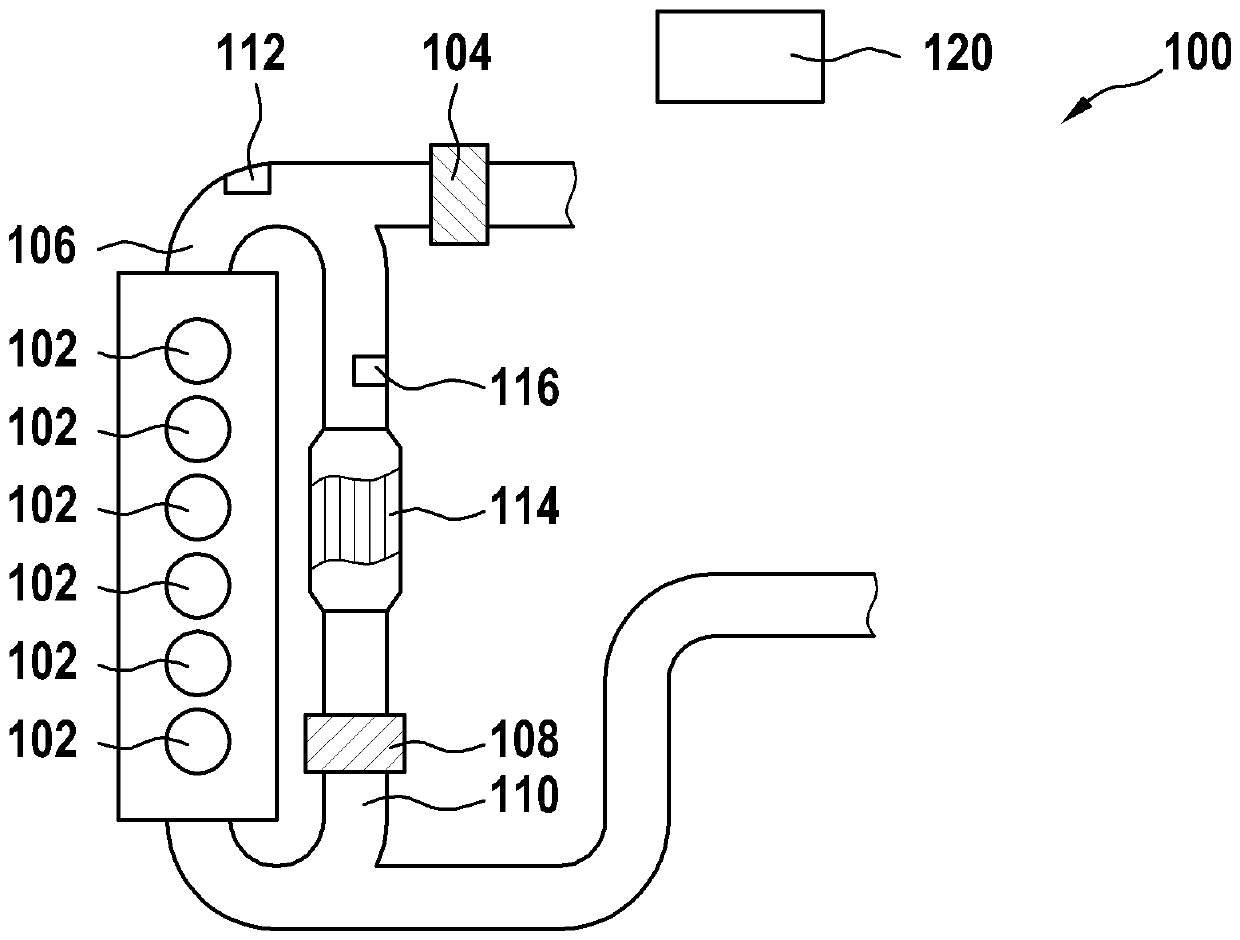

[0022] figure 1 Internal combustion engine 100 is shown schematically. This is a device 100 with a combustion chamber 102 in which a mass flow of air for combustion can be conveyed into the combustion chamber via a throttle valve 104 arranged in an intake manifold 106 .

[0023] Exhaust gas from the combustion can be routed for combustion in the combustion chamber 102 via an exhaust gas recirculation valve 108 arranged in the exhaust gas recirculation path 110 .

[0024] The pressure in intake line 106 can be measured by means of pressure sensor 112 .

[0025] Internal combustion engine 100 includes control unit 120 , which is designed to carry out the method described below by detecting the signal of pressure sensor 112 and outputting actuation signals for throttle valve 104 and exhaust gas recirculation valve 108 .

[0026] The signals of the mentioned sensors can be detected directly by the control unit 120 or received via a communication network, for example a controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com