Low-pressure oil film breaking and atomizing technology and device thereof

An atomization device and low-pressure oil technology, applied in the direction of combustion method, combustion type, burner, etc., can solve the problems of poor adjustability of atomization cone angle, poor oil mist penetration ability, non-stop operation of oil pump, etc., to achieve fog Low gas consumption, significant energy saving effect, stable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

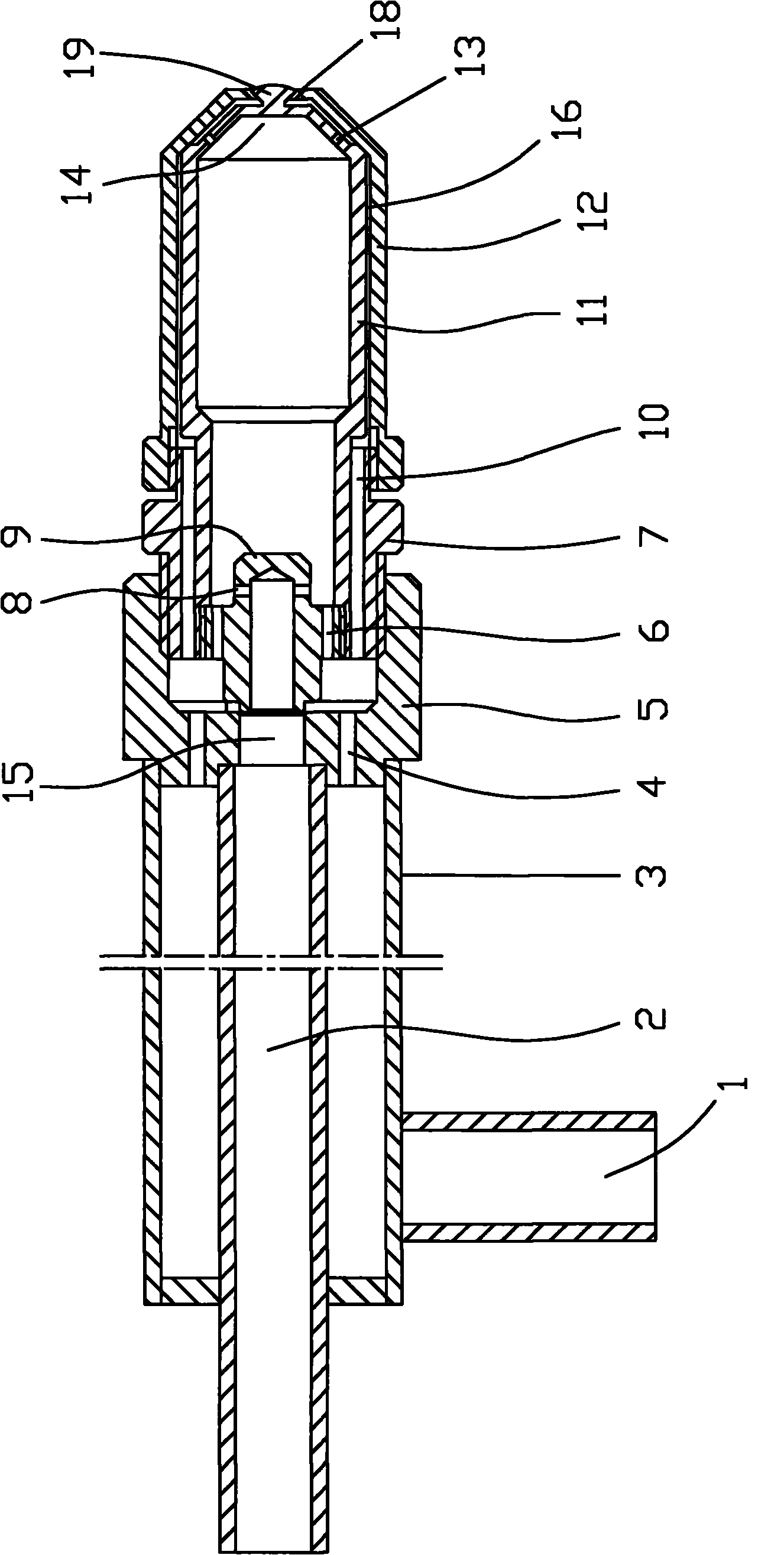

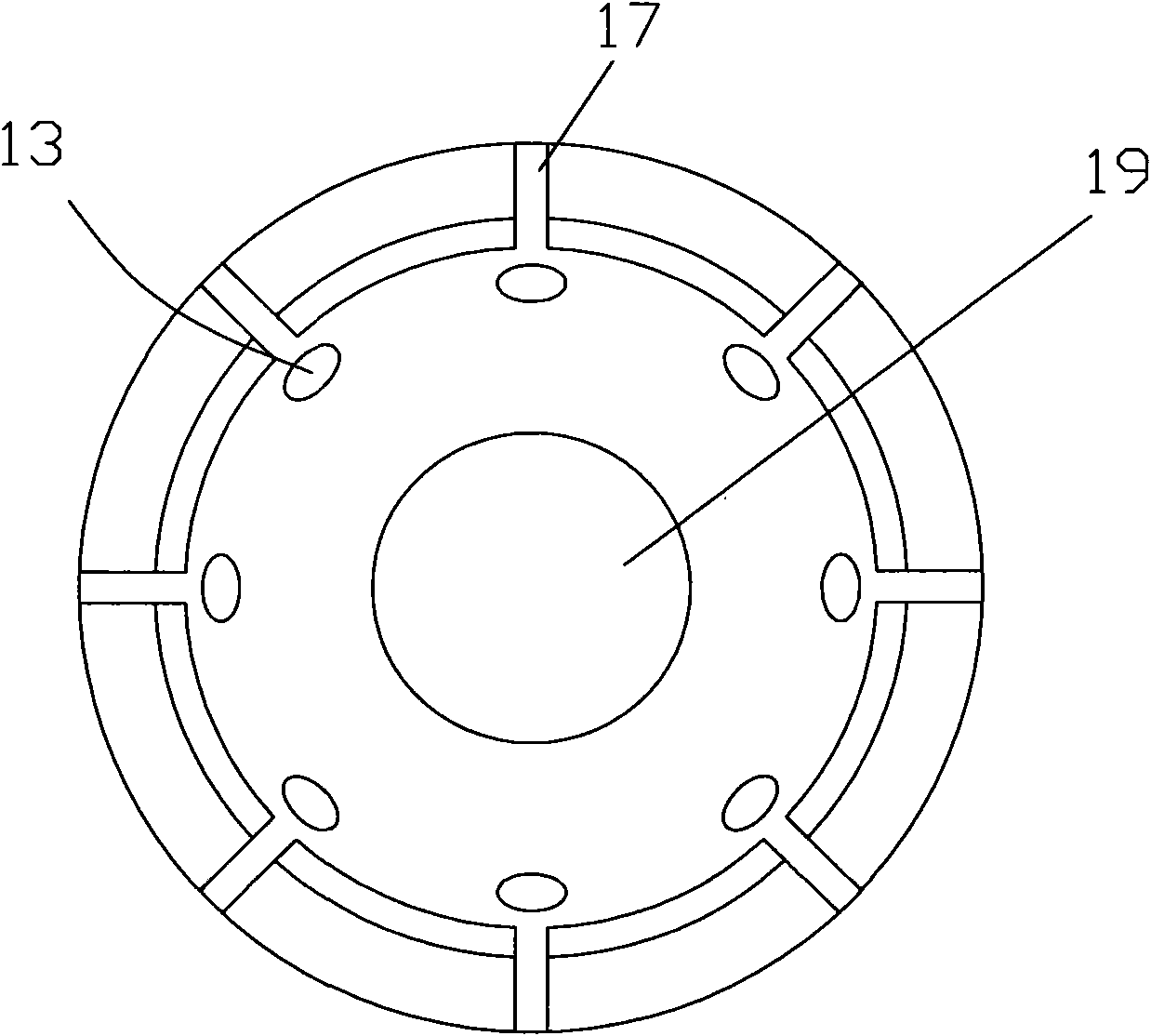

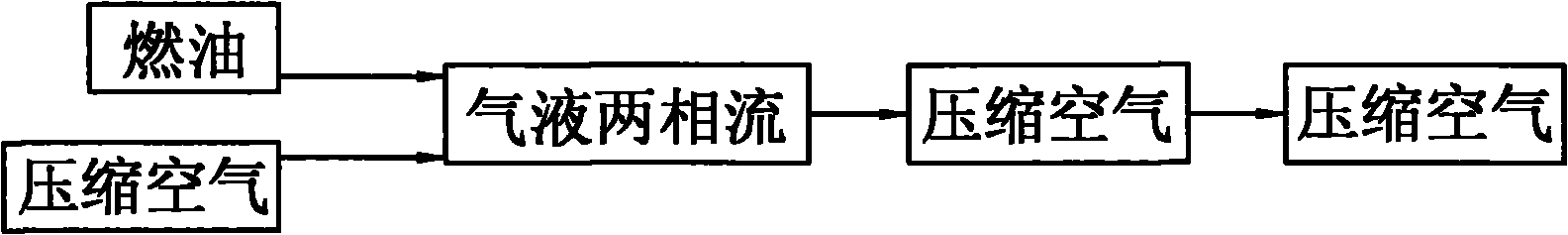

[0030] Such as Figure 1 to Figure 3 As shown, the low-pressure oil film breaking atomization technology of the present invention is specifically: in the gas-liquid two-phase fluid generator, fuel oil and compressed air, steam and other auxiliary gases are formed into a gas-liquid two-phase fluid, and the gas-liquid two-phase fluid includes bubbles flow, slug flow or emulsion flow. The gas-liquid two-phase fluid is sprayed into the furnace through the oil gun, and the injected gas-phase fluid breaks and atomizes the formed oil film at one time by overcoming its strong surface tension, so as to achieve ultra-fine atomization of fuel oil and obtain ultra-fine Fine atomized oil droplets; in the process of primary crushing and atomization, the gas energy is fully and effectively used to achieve the best atomization effect. The gas-liquid two-phase fluid is sprayed from several circular injection holes of the atomization moment provided on the oil gun, and each circular injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com