High-temperature and high-speed stable combustion method and device based on multistage jet flow and rotational flow

A technology of stable combustion and jet flow, applied in the field of combustion, can solve the problems of unstable combustion and ablation, and achieve the effect of reducing the ablation phenomenon, prolonging the service life and realizing the self-cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

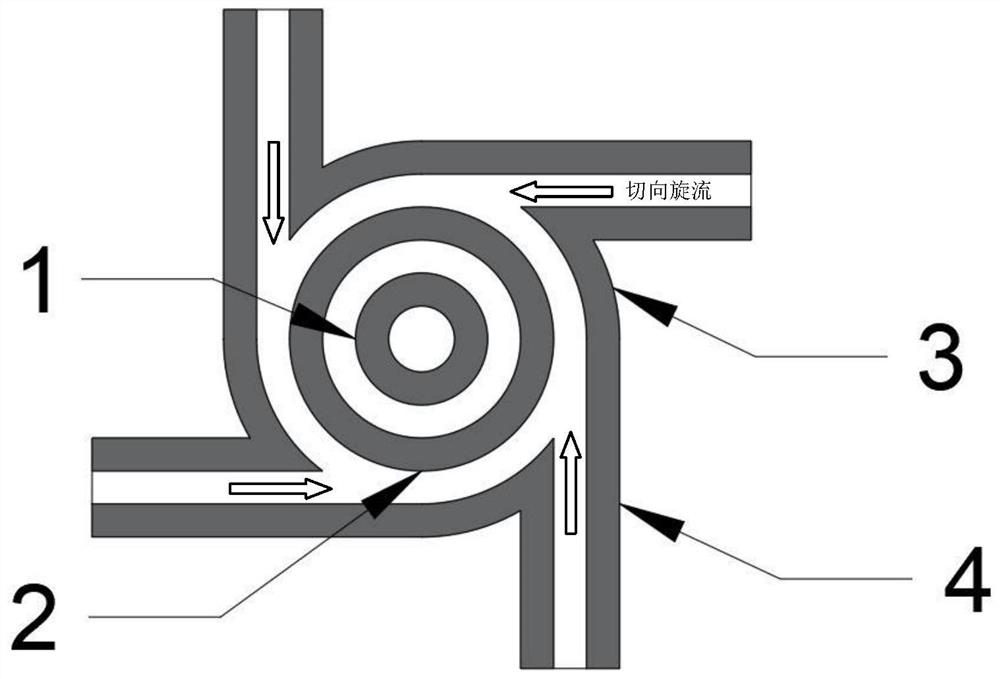

[0031] A high-temperature, high-speed, stable combustion method based on multi-stage jets and swirls disclosed in this embodiment utilizes the flow characteristics and flame stability of axial jet flames and tangential swirl flames, and uses non-premixed high-speed axial jets to provide high-temperature High-speed flame, using pre-mixed swirl to enhance mixing, improve combustion efficiency and maintain stable combustion.

Embodiment 2

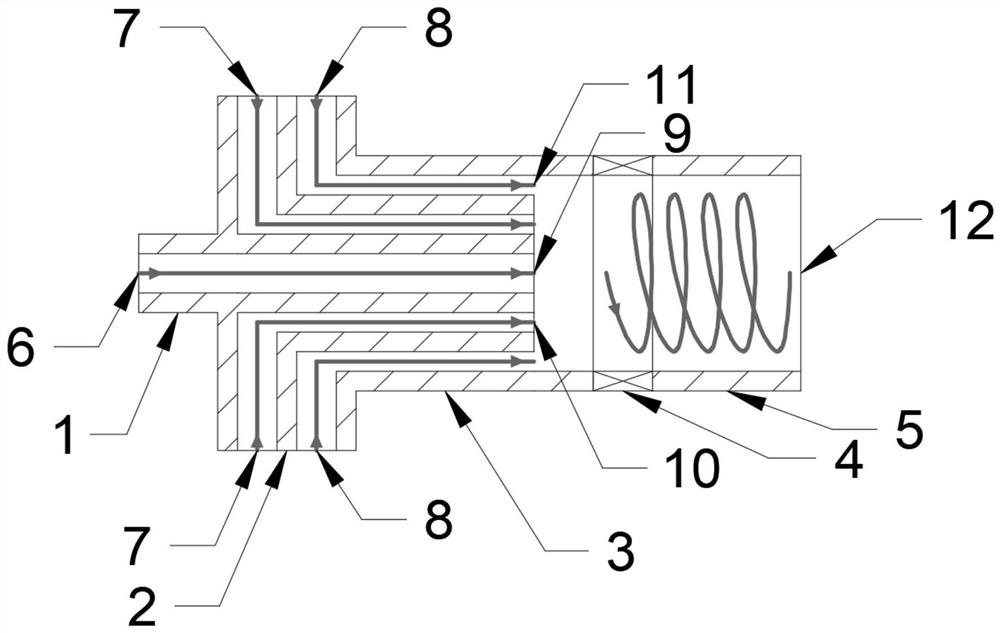

[0033] Such as figure 1 As shown, this embodiment discloses a high-temperature, high-speed and stable combustion device based on multi-stage jets and swirls, including a first-stage axial jet generator 1, a second-stage axial jet generator 2, and a third-stage axial jet generator 3 and tangential swirl generator 4, combustion chamber 5.

[0034] Among them, the first-stage axial jet generator 1 is a hollow cylindrical structure, including an inlet 6 and an outlet 9, which are distributed along the axial direction and are circular; the second-stage axial jet generator 2 is a flanged sleeve structure , including two inlets 7 and one outlet 10, both of which are circular, the two inlets 7 are symmetrically distributed along the radial direction, and the outlet 10 is along the axial direction; the three-stage axial jet flow generating device 3 is a flanging sleeve type structure, including two Two inlets 8 and one outlet 11 are circular, two inlets 8 are symmetrically distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com